Radar level meter working principle:

Radar level transmitters are electronic devices used to measure fluid levels. Radar technology is employed by these transmitters, taking advantage of the 10GHz electromagnetic waves of the microwave X-band bandwidth. Kaidi Sensors supply radar level meters which offer non-contact continuous monitoring of liquid, slurry, powder and solids. Radar sensors can remain accurate even when working temperatures and pressures fluctuate drastically. As these instruments emit low energy beams, they have no adverse effect on humans or the environment when installed in metal or non-metal tanks or pipes. Furthermore, radar level sensors feature a high signal to noise ratio for accurate (2mm) measurement despite rapidly changing levels; this is maintained by the narrow beam angle unaffected by angle of repose.

Radar level transmitters utilize top-down waveguides to send out microwave pulses directed into a containment vessel. Due to gas and vapor species' low dielectric constant, or relative permittivity (Er), these signals can propagate through the headspace. Upon hitting the abrupt change in dielectric between the headspace's reduced-dielectric medium and the elevated-dielectric liquid or solid surface, these pulses are reflected back to their source. An integrated timing system computes how much time is needed for these signales generated from the antennae to return, delivering exact digital precision level measurments based on the dielectric properties of the substance being monitored.

Advantages of radar level meter:

1. Interference echo can be suppressed

This function can be set in the radar transmitter, our radar level meter has digital display and easy operation buttons, users can set this function when needed.

2. The best part is that it can have solids level measurement which our SH series capacitance type level transmitters cannot achieve. It can measure ore level, and powder level in dusty environment.

3. Radar level meter can also be used in some high temperature and pressure conditions by choosing different kinds of precision digital level indicator.

4. Radar sensor can accurately measure level and be the measurement is continuous

This is mainly because the radar level meter signal wave is the electromagnetic wave, so it will not be affected by the environment and also the measurement can be non-contact.

Application:

6GHz radar level gauge is suitable for liquid, paste, granule and block material level and non-contact measurement, suitable for changes in temperature, pressure big; there is an inert gas and volatile.

The measurement method of microwave pulse, can work normally in the industrial frequency band range. The beam energy is low, can be installed on all kinds of metal, non-metallic container or pipe, no harm to human body and environment.

| Suitable for Medium: | Liquid, especially for corrosive liquid |

| Explosion-proof Grade: | Exia IIC T6 Ga/ Exd IIC T6 Gb |

| Measuring Range: | 20m |

| Aerials: | The Rod Antenna (PTFE) |

| Frequency: | 6 GHz |

| Temperature: | -40℃~130℃ |

| Measurement Precision: | ±10mm |

| Process Pressure: | (-0.1 ~ 1.6) Mpa |

| The signal Output: | (4 ~ 20) mA/HART |

| The Scene Display: | Four LCD /Can be programmed |

| Power Source: | Two-wire (DC24V) 、Four-wire (DC24V/AC220V) |

| Repeatability: | ± 1mm |

| Outer Covering : | Aluminum /Plastic /Stainless steel |

| Connection: | With PTFE plate flange |

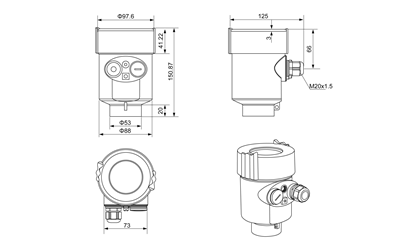

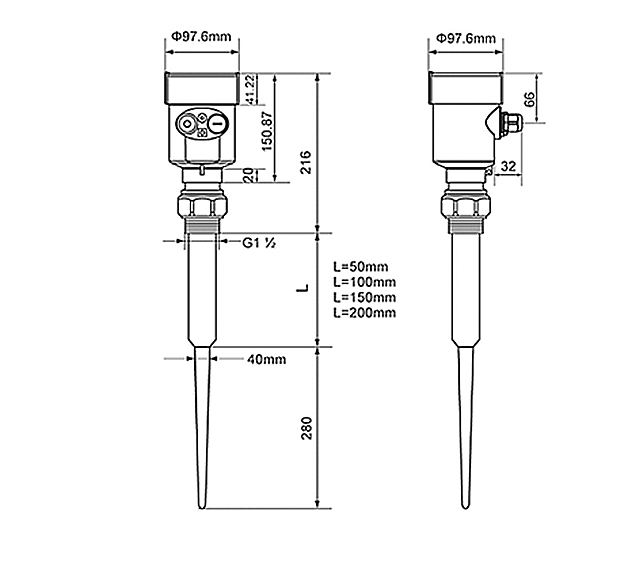

1. Dimensions of Instruments

l The rod antenna radar size (unit: mm)

l

The rod antenna radar size (unit: mm)

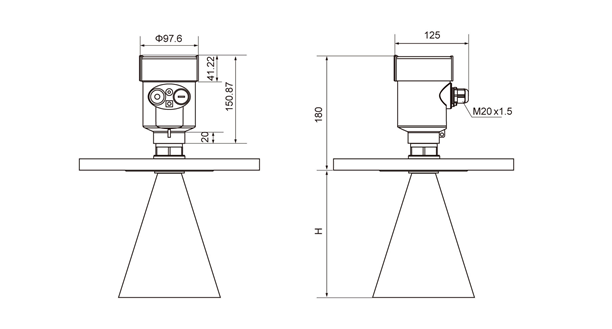

l Horn antenna size (unit: mm)

l Horn size (unit: mm)

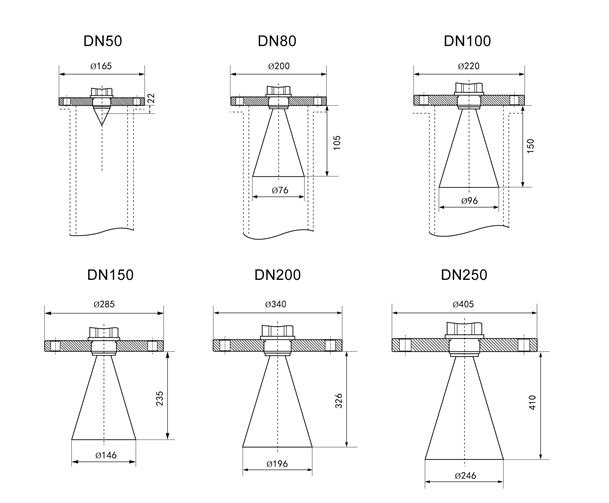

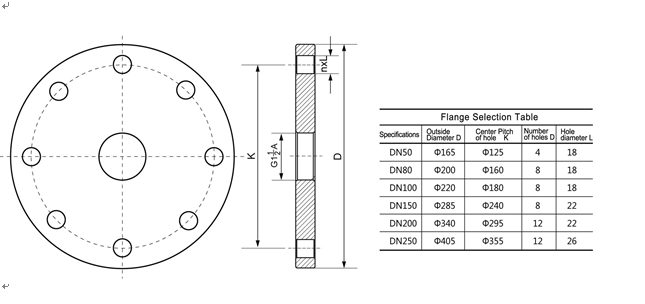

l Flange Selection (unit: mm)

2. The Electrical Connection

l The power supply voltage:

| (4~20)mA/HART (Two wire system) | The power supply and the output current signal sharing a two core shield cable. The supply voltage range see technical data. For intrinsically safe type must be a safety barrier between the power supply and the instrument. |

| (4~20)mA/HART(Four wire system) | Separate power supply and the current signal, respectively using a two-core shielded cable. The supply voltage range see technical data. |

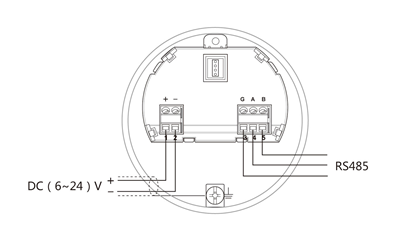

| RS485 / Modbus | Power supply and Modbus signal line are separated, respectively using a two-core shielded cable, the power supply voltage range see technical data. |

l Connection mode:

Ø

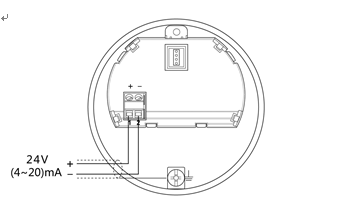

24V two wire wiring diagram as follows:

Ø

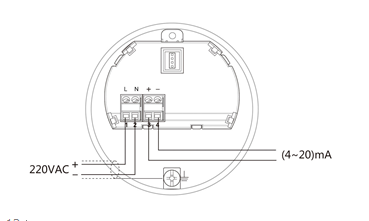

220V four wire connection is as below:

Ø 24V RS485/Modbus wiring diagram as follows:

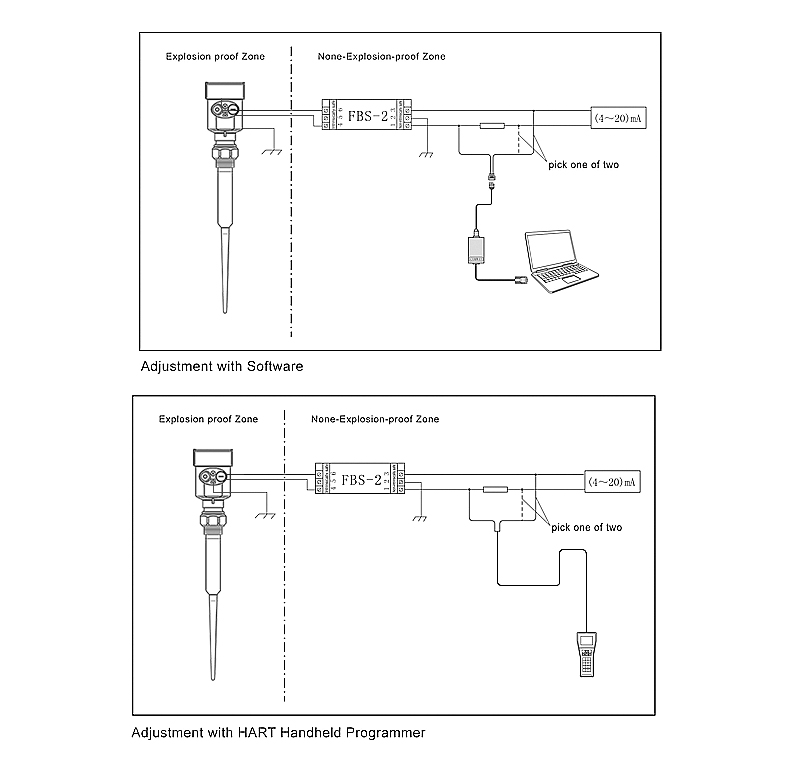

l Explosion Proof Connection

The intrinsic safety version sensors (Exia IIc T6) use Alu-die casting housing and filling Silicone rubber sealants internal structure aimed to prevent sparks resulted from circuit failure from leaking out. It is applicable for the continuous level measurement of flammable medium under Exia IIc T6.

A safety barrier FBS-2 must be used together with the intrinsic safety instrument. It is an associated device to this product for the power supply of this product. The main specification is intrinsic safety: Exia IIC, voltage of power supply: 24V DC±5%, short-circuit current: 135mA, operating current: 4...20mA.

All cables must be shielded. The max length is 500m for the cable from the barrier to the sensor. Stray capacitor≤0.1μF/Km, stray inductance 1mH/Km. Instrument must be connected to the ground potential. Any unapproved associated device is not allowed to be used.

l Protection grade:

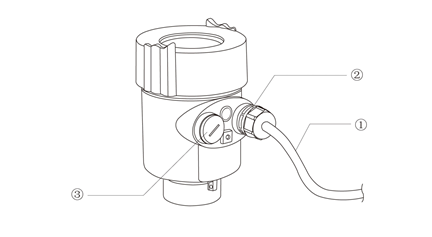

This instrument meets the protection class IP66/67 requirements, please ensure the waterproof cable sealing head. The following diagram:

3. Programming and Debugging

l There are three kinds of debugging method:

1) Display / Keyboard

2) Host debugging

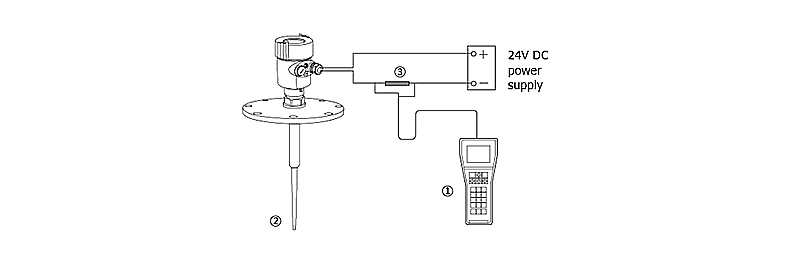

3) HART handheld programmer

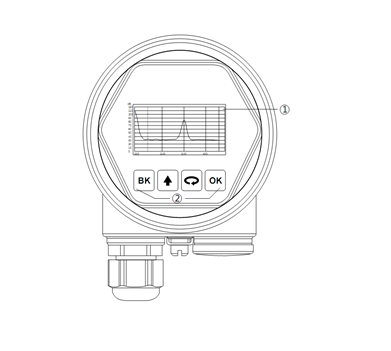

l Display / Keyboard:

Please debug the instrumentation by four buttons on the display screen. There are three debug menu languages optional. After debugging is generally used only for display, through the glass window can read measured value very clearly.

l Display / Keyboard

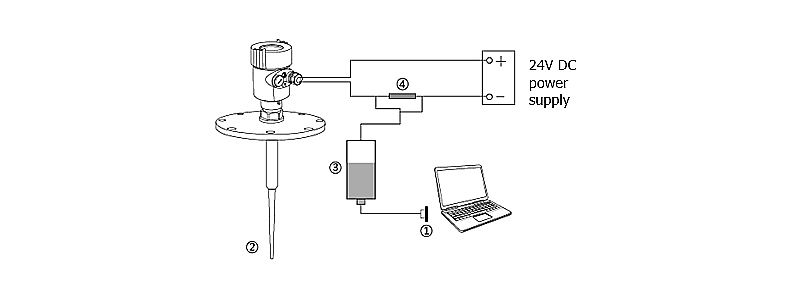

l PC debugging:

Connected to PC by HART

l HART handheld programmer:

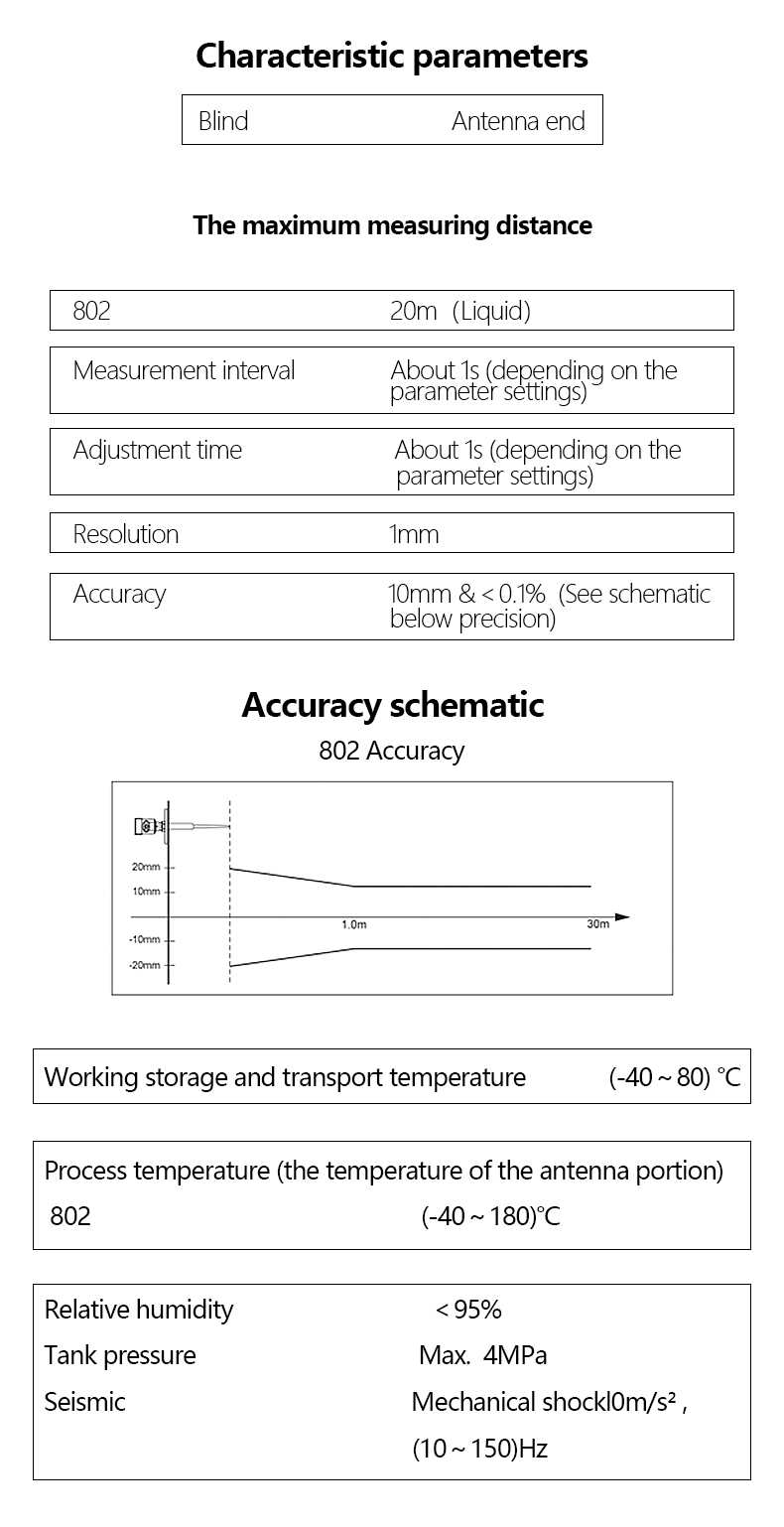

4. Technical Parameters

| General data | |

| Materials | |

| Antenna | PTFE, PP |

| Outer Covering | Aluminum, Plastic, Anti-static PP, Stainless steel 316 |

| The seal housing and the housing | Silicone Rubber |

| Shell window | Polycarbonate |

| Ground terminal | Stainless steel |

| Process connection | |

| 801 | G1½″A Thread & 1½″NPT Thread / Flange (optional) |

| 802 | With PTFE plate flange |

| 803 | Stainless Steel Flanges |

| 804 | Stainless Steel Flanges |

| 805 | Stainless Steel Flanges |

| 806 | Stainless Steel Flanges |

| Supply voltage | |

| Two-wire | |

| Standard | (16~26)V DC |

| Intrinsically Safe | (21.6~26.4)V DC |

| Power Consumption | Max.22.5mA |

| Allowable ripple | |

| <100HzH47 | Uss < lV |

| - (100~100K)Hz | Uss < l0mV |

| Flameproof | |

| (22.8 ~ 26.4) V DC 2-wire system | |

| (198 ~242)V AC 4-wire system / 110V AC 4-wire system | |

| Power Consumption Max. 1VA,1W | |

| Cable parameters | |

| Cable entry / plug | 1 M20xl.5 cable entry (cable diameter 5 ~ 9mm) |

| 1 blind blocking M20xl.5 | |

| Spring terminals | For wire cross-section 2.5mm² |

| Output parameters | |

| The output signal | (4~20)mA / HART |

| Resolution | 1.6μA |

| Fault signal | Current output unchanged;20.5mA;22mA;3.9mA |

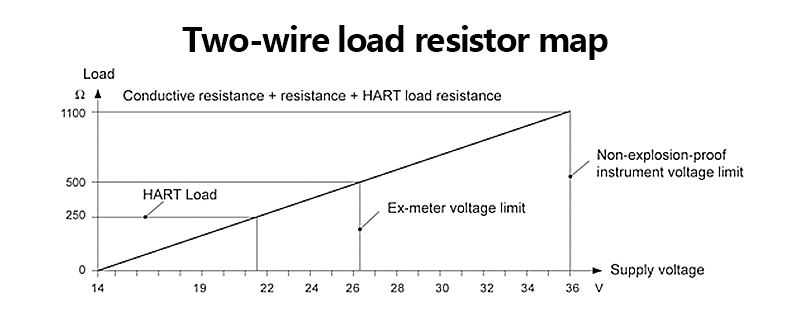

| Two-wire load resistor | See below |

| Four-wire resistive load | The maximum 500Ω |

| Integration time | (0 ~ 36) s, adjustable |

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist