PRODUCT OVERVIEW

6GHz intelligent series radar level meter is suitable for non-contact continuous measurement of the level of liquid slurry, particle material and block material, suitable for large temperature and pressure changes;

The microwave pulse measurement method is used in the presence of inert gas and volatiles, and can work normally in the range of industrial frequency band. The beam energy is low, and can be installed in various metal and non-metal containers or pipelines, which does no harm to human body and the environment.

THE PRODUCT PRINCIPLE

Antenna system to launch and microwave receiving energy is very low, very short pulse. Radar waves travel with the speed of light. The running time can be through the electronic components are converted into a signal. Measurement of this special time extension method can realize stable, accurate in a very short period of time.

Even if the condition is very complex, the presence of false echo, with the latest micro- processing technology and debugging software also can analyze the level echo accurately.

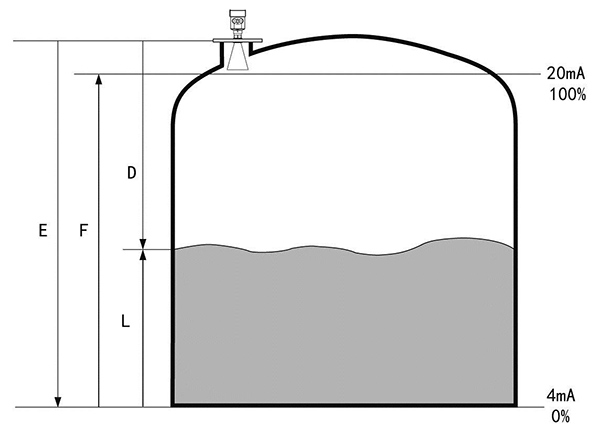

Microwave antenna to receive the reflected pulse and transmitted to the electronic circuit, a microprocessor to signal processing, to identify the micro pulse generated on the material surface echo. Echo recognition is completed by the pulse system, the accuracy can reach millimeter level. From the material surface distance between D and T pulse is proportional to the time travel: D=C×T/2 Where C is the speed of light Because of the air tank is a known distance E, L: L=E-D By setting the empty tank height E (= zero), the full height of F (= full scale) and some application parameters, application parameters automatically makes the instrument to measure the environment. 4 - 20mA with a corresponding output.

This instrument fully meets the requirements of protection class IP66/67.

This instrument fully meets the requirements of protection class IP66/67.

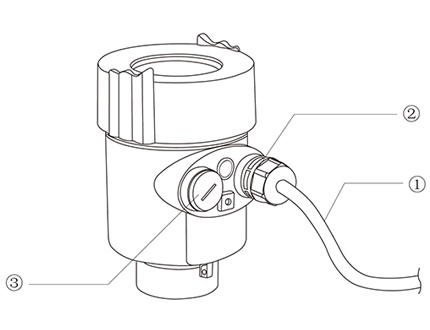

Please make sure that the cable sealing head is waterproof. As shown

How to ensure that the installation meets the requirements of IP67.

Please make sure that the sealing head is not damaged.

Please make sure that the cable is not damaged.

Please ensure that the cable used meets the requirements of the electrical connection specification.

Before entering the electrical connection, bend the cable downwards to ensure that water

does not flow into the housing, see ①

Please tighten the cable sealing head, see ②

Please plug the unused electrical connections with blind plugs, see ③

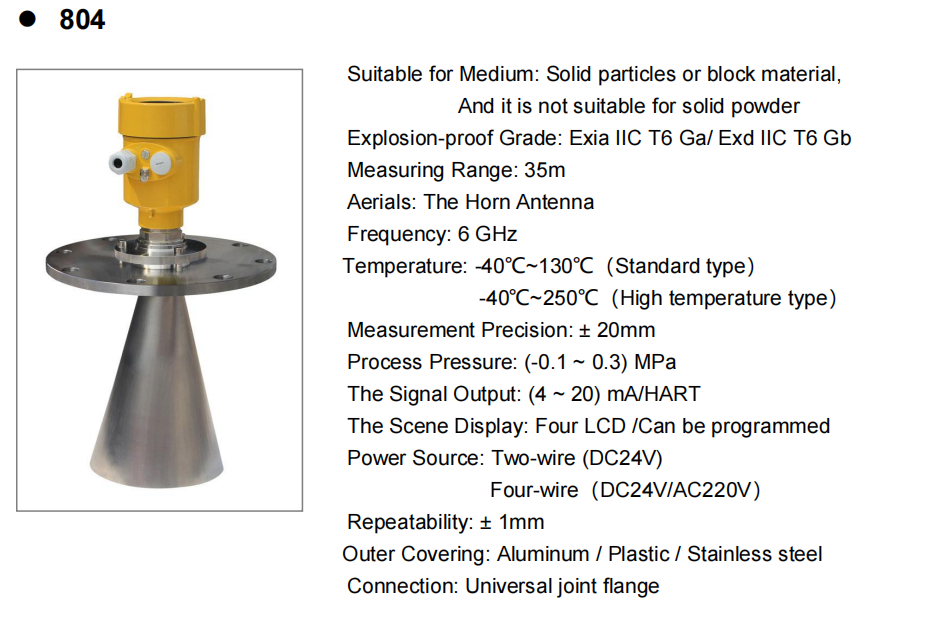

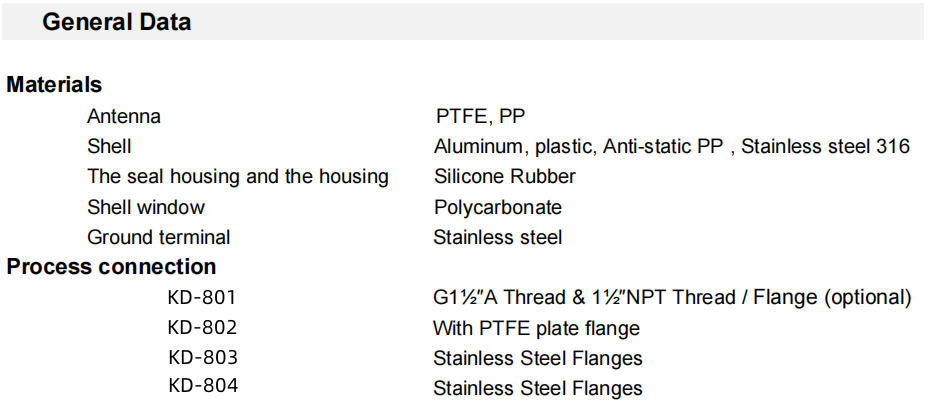

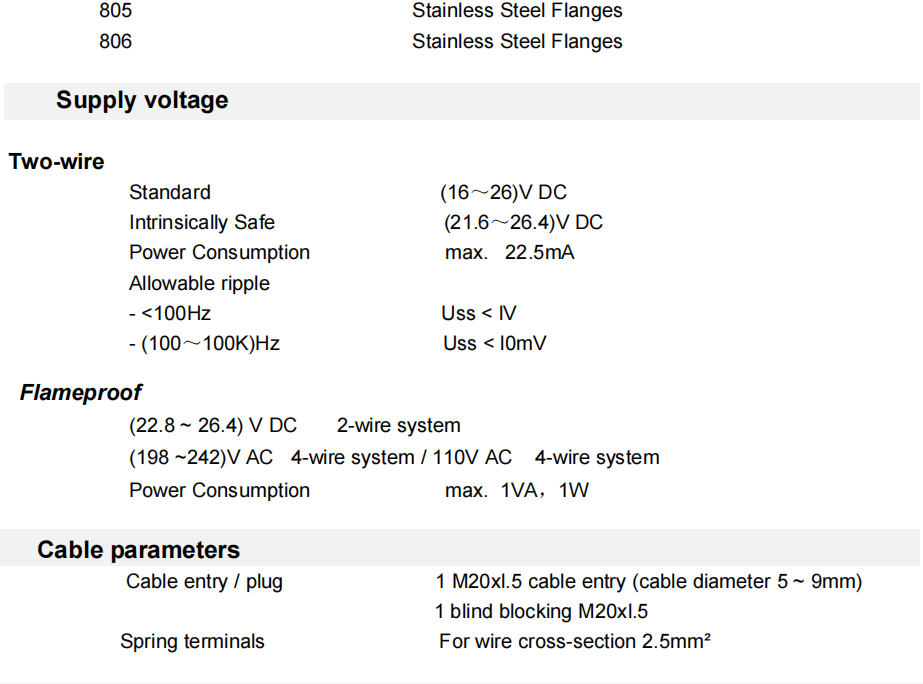

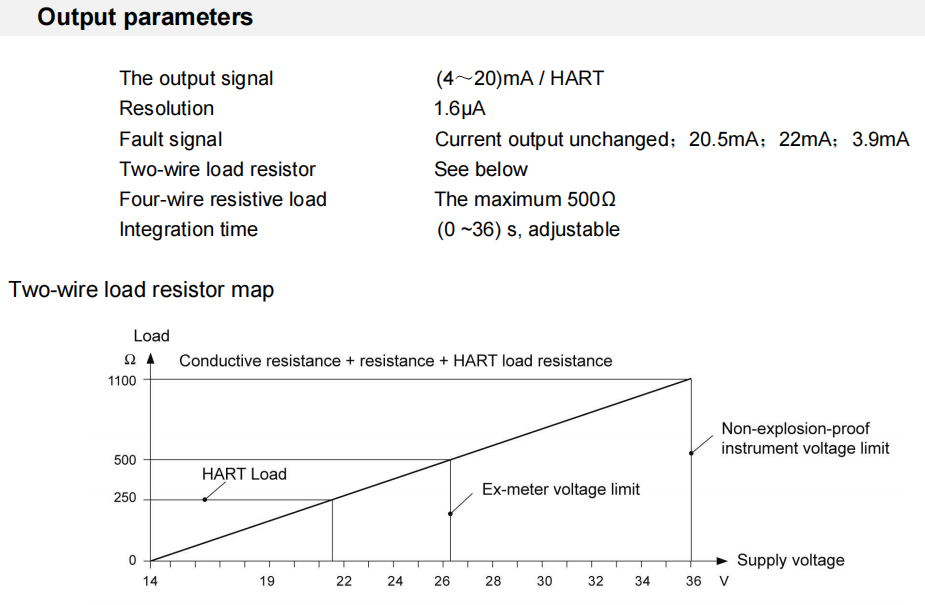

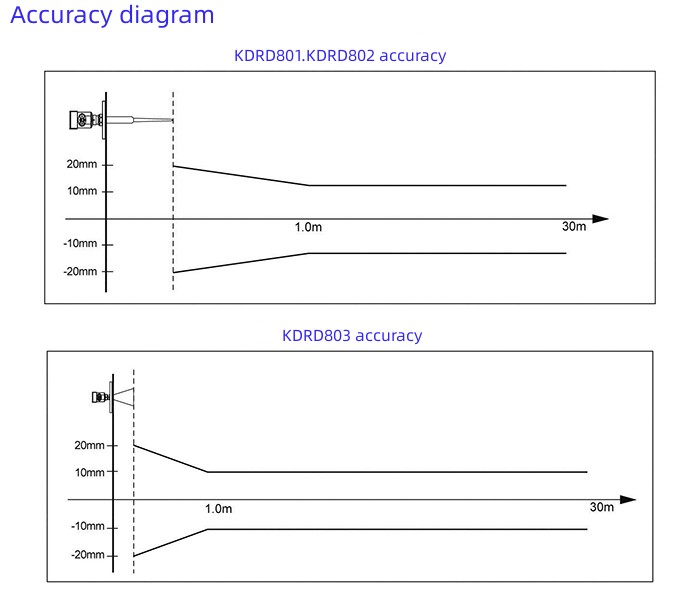

PRODUCT SPECIFICATION

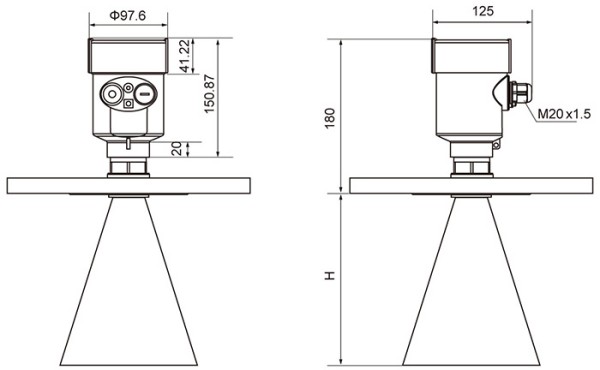

APPEARANCE OF SIZE

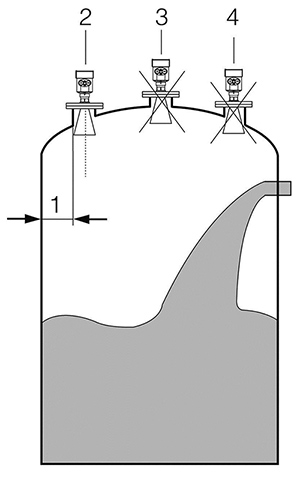

The recommended position (2), the outer wall of tank wall to install pipe shall

The recommended position (2), the outer wall of tank wall to install pipe shall

meet the following from the tank wall best distance to tank diameter of 1/4 or 1/6,

the minimum distance from the installation of tank wall as the measurement range of 1/10.

For example: liquid level of storage tank 10m, and the tank wall install the minimum distance of 1m.

Cannot be installed above the feeding port (4).

Cannot be installed in the central position (3), if installed in the central, yield multiple false echo,

clutter echo will lead to real signal loss.

If you can't keep the instrument and the tank wall of the tank wall distance, the medium will

adhesion caused by false echo, when debugging instrument should be false echo storage.

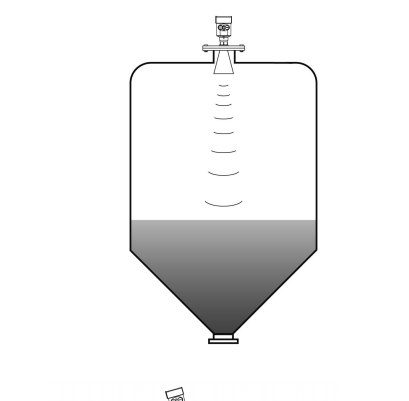

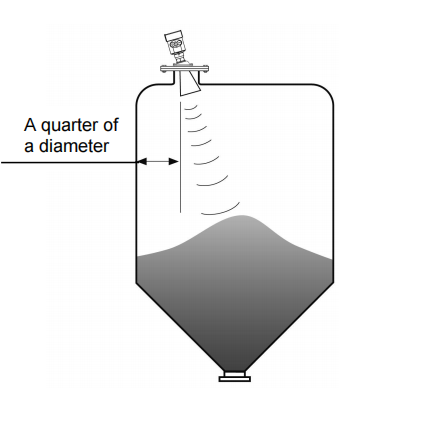

The top conical tank level, can be installed at the top of the tank is intermediate,

can guarantee the measurement to the conical bottom.

A feed antenna to the vertical alignment surface. If the surface is rough, stack angle must be used to adjust the angle of Universal joint flange of the antenna to the alignment surface.

(Due to the solid surface tilt will cause the echo attenuation, even Loss of signal.)

Tank installation instructions:

Tank installation instructions:

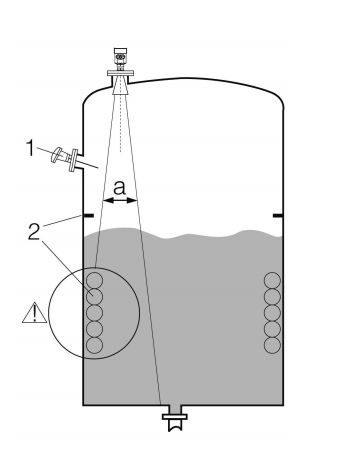

In the signal beam, should avoid the following installation:

Such as: (1) the limit switch, temperature sensor.

Symmetric devices such as (2): vacuum ring, a heating coil , Baffle plate etc.

If the tank (1) (2) interference object, should be guided wave tube measurement.

Best installation options:

Antenna size: larger antenna, beam angle smaller, interfering echoes will be weaker.

Antenna adjustment: the antenna to adjust to the best measurement position.

Guided wave radar take over: The installation of the wave guide is used to avoid disturbing the echo.

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist