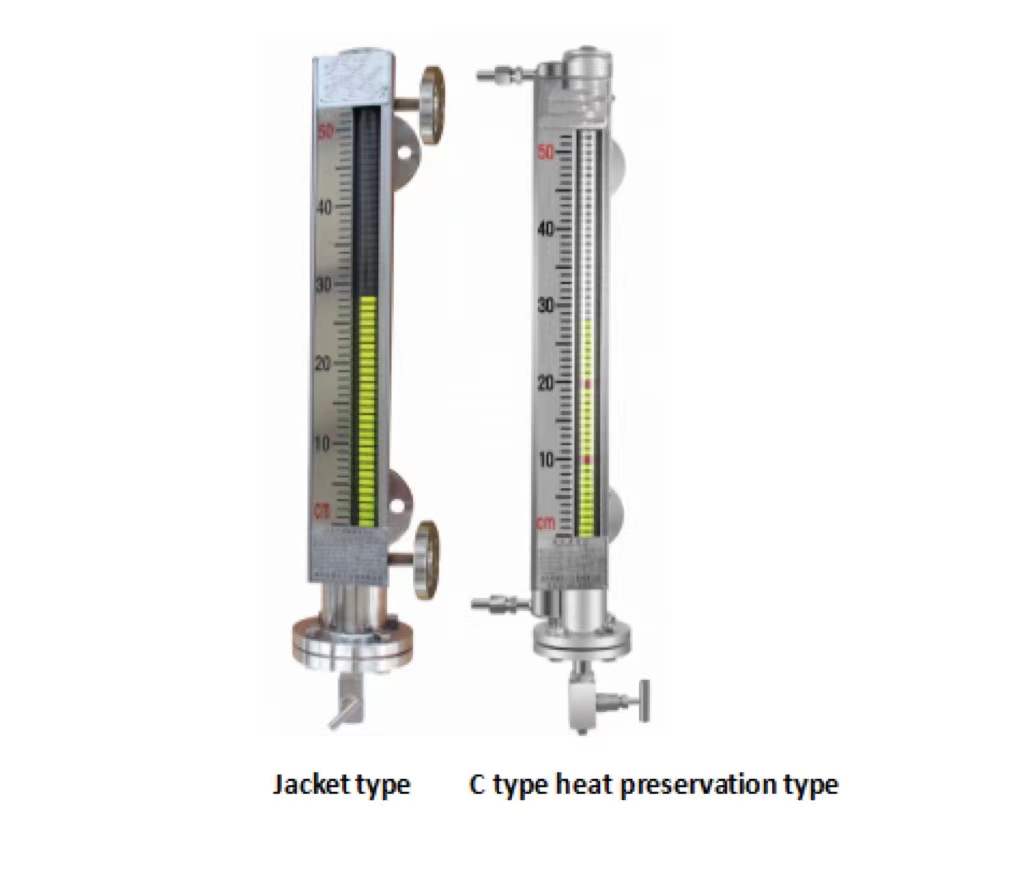

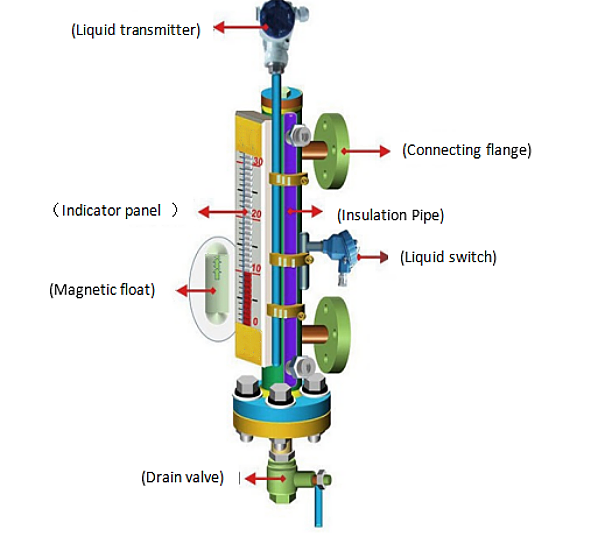

Magnetic level gauges work on the principle of communicating vessels, therefore the level in the measuring chamber will be the same as the level in the vessel.The UZC jacketed magnetic level gauge adopts a jacketed design, which achieves the purpose of temperature control by vacuuming the jacket layer or introducing a circulating medium, which provides reliable measurement of liquids that are easy to crystallize or have poor fluidity at lower temperatures. Measurement scheme. The thermal insulation jacket plays the role of heating and thermal insulation, and can also be passed into the cooling medium to cool down. It is suitable for liquid level measurement in chemical equipment where antifreeze, thermal insulation, high temperature and heating are required. The jacket forms include steam, circulating water, and vacuum jacket methods. The biggest advantage of this series of products is the integrated structure of the jacket and the magnetic level gauge chamber, which is convenient for installation.

Magnetic float level sensors and their mechanical counterparts both rely on a sealed permanent magnet inside a float to control a mechanical switch, either through contact or proximity to a reed switch. In the case of mechanically actuated floats, a micro switch is connected directly to the float. When selecting the appropriate stem and float for these sensors, factors such as chemical compatibility, temperature, specific gravity (density), buoyancy, and viscosity must be taken into consideration. For instance, larger floats can still remain buoyant with liquids that have a low specific gravity of 0.5 or higher. Temperature-induced changes in specific gravity and viscosity are also important considerations when choosing the material for the float.

This magnetic level gauge is available with a full plastic indication rail or with stainless steel flaps in a aluminium or stainless steel 316 housing.Because of the construction of the flaps, one side white and on the other red / orange it is possible to see the level over a greater distance or in darker places.With the available “Pointers” it is possible to set the visual limits on the indicating rail on every level you require.

When the magnetic level gauge is fitted with magnetic switches it is possible to get a signal. With more switches you can make a pump control (pump on / off) and / or create a high / low alarm. Beside or instead of level switches a reedchain transmitter can be mounted, this reedchain has an standard output signal of 4-20 mA.Magnetic level gauge are also suitable for interface reading. The float will sink into the medium with the lower density and will float on the medium with the higher density.

The UZC jacketed magnetic level gauge adopts a jacketed design, which achieves the purpose of temperature control by vacuuming the jacket layer or introducing a circulating medium, which provides reliable measurement of liquids that are easy to crystallize or have poor fluidity at lower temperatures. Ground survey plan. The thermal insulation jacket plays the role of heating and thermal insulation, and can also be passed into the cooling medium to cool down. It is suitable for liquid level measurement in chemical equipment where antifreeze, thermal insulation, high temperature and heating are required. The jacket forms include steam, circulating water, and vacuum jacket methods.

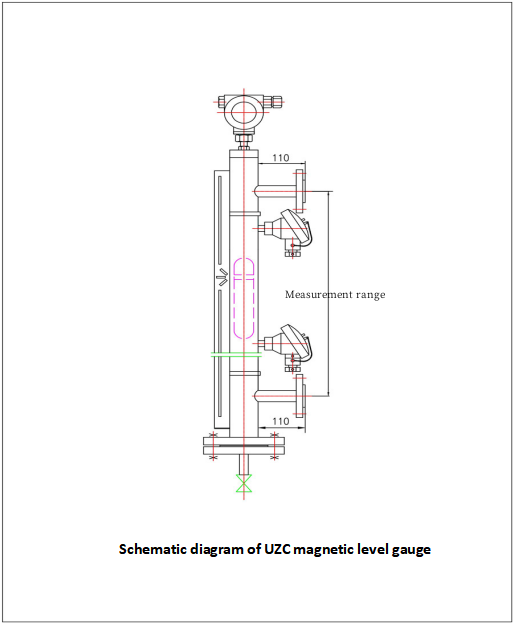

| Measuring range | 300- 15000mm | Rated temperature | ≤450℃ |

| Measurement accuracy | ±5mm | Medium viscosity | ≤0.02Pa.S . |

| Nominal pressure | ≤42MPa | Following speed | ≤0.08m/s |

| Medium density | ≥0.35g/cm3 | Transmission output | Two-wire 4-20mA, DC600Ω load |

| Medium density difference | ≥0.03g/cm3 (measurement interface) | Connection flange size | HG/T20592-20635-2009, DN20, PN2.5 If other flanges are used, please indicate when ordering |

| Model | illustrate | |||

| UZ | Kaidi Magnetic Level Gauge | |||

| Type of installation | C | Side loading | D | Top loading |

| Panel type | A1 | -40-80℃ normal temperature | Z1 | -190~-20℃ Vacuum |

| A2 | 80-180℃ medium temperature | Z2 | -20-180℃ Vacuum | |

| A3 | 180-350℃ high temperature | Z3 | Vacuum at 180-350℃ | |

| A4 | 350-450℃ ultra high temperature | E | -40℃-450℃ magnetic sensitivity | |

| Pressure Rating (MPa) | 1 | PN1.0 | 2 | CL150LB |

| 1.6 | PN1.6 | 5 | CL300LB | |

| 2.5 | PN2.5 | 11 | CL600LB | |

| 4 | PN4.0 | 15 | CL900LB | |

| 6.3 | PN6.3 | 26 | CL1500LB | |

| 10 | PN10.0 | 42 | CL2500LB | |

| 16 | PN16.0 | |||

| Range-Density | Range mm-density g/cm³ | |||

| Flange Material | P | 304 | PF | 304 lined with fluorine |

| PL | 316L | C | Carbon steel | |

| PP | PP | Ti | titanium | |

| Flange Diameter | 15 | Side mounted DN15 | 50 | Top loading DN50 |

| 20 | Side mounted DN20 | 65 | Top loading DN65 | |

| 25 | Side mounted DN25 | 80 | Top loading DN80 | |

| 32 | Side mounted DN32 | 100 | Top loading DN100 | |

| 40 | Side mounted DN40 | 125 | Top loading DN125 | |

| 50 | Side mounted DN50 | 150 | Top loading DN150 | |

| 65 | Side mounted DN65 | 200 | Top loading DN200 | |

| 80 | Side mounted DN80 | 250 | Top loading DN250 | |

| Flange sealing surface | Omit | Raised face | FM | Concave |

| F | Convex | FF | Full plane | |

| Tube material | P | 304 | P1 | 321 |

| PL | 316L | P4 | 304L | |

| PF | 304 lined with fluorine | Ti | titanium | |

| PP | PP | |||

| Insulation/anti-frost | Omit | No | ||

| C | Type C insulation pipe (recommended) | |||

| T1 | Set vacuum insulation | |||

| T2 | Jacket insulation | |||

| D1 | 40-90 constant temperature electric heating | |||

| D2 | 120°C temperature control adjustable electric heating | |||

| S1 | Anti-frost below -40°C | |||

| S2 | -40~-20℃ anti-frost | |||

| Accessories | Y | Remote transmission level gauge | ||

| K | Alarm switch | |||

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.