PRODUCT DESCRIPTION:

It is necessary to have a water level gauge at each end of the boiler as the ship moves. To observe the water level accurately, it is necessary to have a water level gauge at each end of the boiler. Whenever the boiler pressure exceeds 17 bar, plate glass-type water level gauges are used.In factories, chemical plants, electrical substations, and other liquid storage systems, water level indicator circuits are used. This simple system can be used for monitoring sump pits (to control pump activation), detecting rainfall, and detecting leaks.Capacitive, ultrasonic, frequency, guided wave GWR, and pressure transducers are the five basic types of commercially available water level indicators.

What is the purpose of water level gauge?

The water level indicator circuits are used in factories, chemical plants, electrical substations, and in other liquid storage systems. This simple system can be used to monitor a sump pit (to control pump activation), detect rainfall, and detect leaks.

BENEFITS OF WATER LEVEL INDICATORS

Easy to install

Very little maintenance

Compact design

Automatic save you can save manual labor time

Consumes very little energy, perfect for continuous operation

Shows incitation of water levels in any type of tank

Automatic water level indicators ensure no overflows or running of dry pumps

Saves money by using less water and electricity

Can help avoid seepage of walls and roofs due to tanks overflowing

Two-color mica water level meter is a once-in-place direct reading instrument for monitoring water level in steam boilers or other pressure vessels in power plants, petrochemicals and industrial and mining enterprises, which is a new type of two-color water level meter successfully developed on the basis of various transmissive two-color water level meters at home and abroad, which has the characteristics of high measurement accuracy, good observation effect and long service life of window components.

Self-flushing two-color water level meter is based on the traditional two-color water level meter on the body of the functional design, adding a strong flushing function.

A condenser can be added to the top of the water level meter body, and the condenser is separated by a spacer with a middle hole, and is offset to the outside. Adding a partition is to prevent the flow of condensate to one end, to the outside because the outside temperature is low, the formation of condensate faster, the purpose is to prevent the flow of condensate in the two columns of the window condensate is not as much. When the saturated steam in the steam ladle flows through the condenser, using the heat dissipation function of the condenser, a large amount of pure water without salt is formed, and this pure water continuously rinses the observation window along the inner surface of the two windows, forcing the dirt attached to the mica of the observation window to be washed away. More importantly, a large amount of pure water flows back into the body cavity, and continuously replaces the saturated water in the body, which eventually turns the saturated water in the body cavity into pure water without salt and impurities, making the window free of hanging scale, achieving high color clarity and durability, improving the observation effect and extending the service life of the window component.

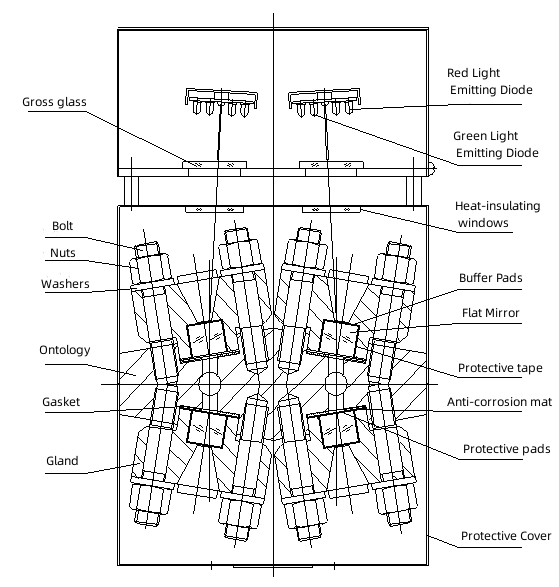

PRINCIPLE STRUCTURE:

WORKING PRINCIPLE:

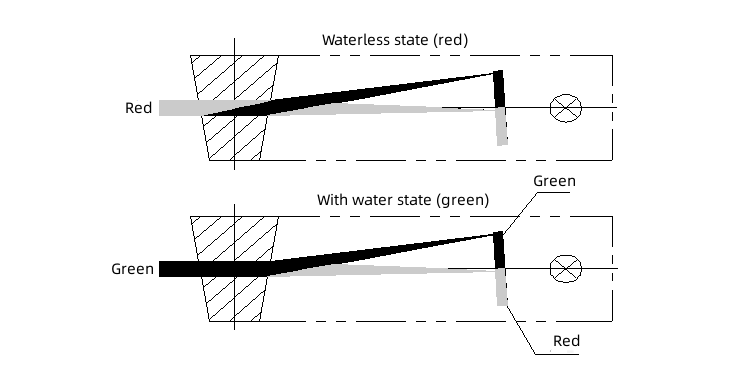

Light from the light source through the red and green filter lens, shot to the water level meter body liquid cavity. In the vapor phase part of the cavity, the red light is directed to the front, while the green light is obliquely shot to the wall and absorbed. And in the liquid phase part of the cavity, due to the refraction of the water level so that the green light is shot to the front, while the red light is oblique to the wall, so in front of the observation, showing the vapor red water green.

TECHNICAL PARAMETER:

| Monitoring method | Direct front visual or color monitor monitoring |

| Water level display | Color separation according to medium, steam red, water green |

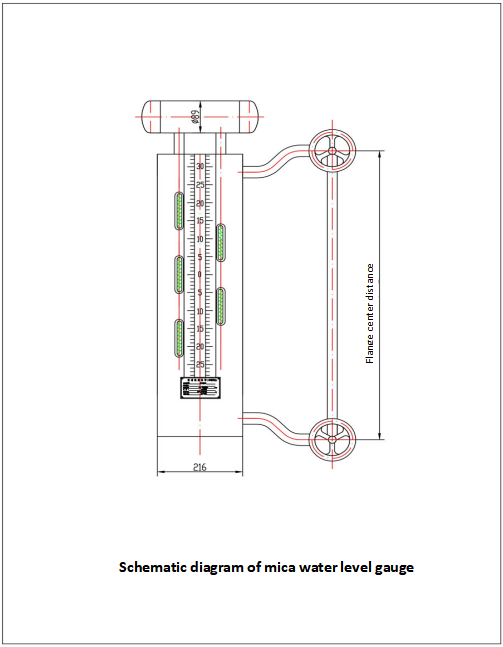

| Installation center distance | 670mm or according to user requirements |

| Lighting source | 24V DC 60W Light Emitting Diode (LED) |

| Interface form | Welding or flange connection |

| The visible range can also be specially manufactured according to user requirements | |

SELECTION TABLE:

| Model | illustrate | |||

| UBYS | Kaidi mica two-color water level meter | |||

| structure type | 1 | Single row | 2 | Double row |

| Process connection | SW | Flangeless welding type | F | Flange type |

| Connection specifications | Omit | Liquid level monochrome | 15 | DN15 |

| 20 | DN20 | 25 | DN25 | |

| 32 | DN32 | 40 | DN40 | |

| 50 | DN50 | 65 | DN65 | |

| 80 | DN80 | 100 | DN100 | |

| Installation direction | L | Installation on the left | R | Installation on the right |

| Pressure rating (MPa) | 4 | PN40 | 5 | Class300 |

| 6.3 | PN63 | 10 | PN 100 | |

| 11 | CL600LB | 15 | CL900LB | |

| 16 | PN160 | 25 | CL1500LB | |

| 42 | CL2500LB | |||

| Range | Range (mm) | |||

DIMENSIONS:

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.