The intelligent float level transmitter is designed on the Archimedes buoyancy principle. It is used to continuously measure the level, interface or density of liquids in industrial applications. This product is sturdy and durable. The measured value can be converted into analog and digital signals. . Through PC or control system, digital communication is convenient for complete operation and configuration. Even in extremely high temperature, high pressure and strong corrosive liquids, the level gauge can always measure stably and with high precision. It is approved to be installed in an explosive gas environment and is widely used in liquid level measurement and control in the production process of various industries such as refining, petroleum, chemical, medicine, and food.

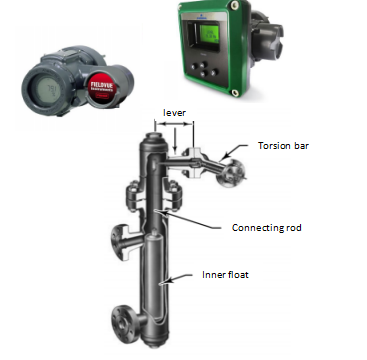

UTD series intelligent float liquid (boundary) level transmitter is composed of intelligent liquid level controller (meter head) and measuring chamber, measuring mechanism, float, torque tube assembly, etc. The change in the liquid level of the measured medium causes a change in the force position of the inner float, which is transmitted to the torsion tube assembly, so that the torsion tube and the mandrel rotate synchronously. At the same time, the magnetic steel component fixed on the torsion tube core shaft undergoes rotational displacement, which changes the magnetic field detected by the Hall effect sensor. The sensor converts the magnetic field signal into an electrical signal. The intelligent level controller uses the controller and related electronic circuits to measure process variables, provides current output, drives a liquid crystal display (LCD) and provides HART communication capabilities. The controller receives the environmental temperature compensated and linearized electrical signal, and can also compensate for the change in liquid density caused by the process temperature change, and output and provide a 4-20mA current output signal. LCD can display analog output, process variables, process temperature (if RTD is installed), torque tube rotation angle and variable percentage range, etc.

| Liquid density | ≥ 0.2 g/cm3 | Minimum density difference | ≥ 0.08g/cm3 |

| Measuring range | 300~3000mm | Medium temperature | -196~500℃ |

| Power supply | DC24V | Output signal | 4-20mA+HART |

| Accuracy class | 0.5 level | Ambient temperature | -40~60℃ |

| Torque tube material | 316L、Inconel600 OR HasetlloyC-276 | ||

| Inner float material | 304, 316L, 321 or according to user requirements | ||

| Outer float material | Carbon steel, 304, 316L or according to user requirements | ||

| Nominal pressure | ≤ 42MPa | Nominal diameter | DN25 or according to customer requirements. |

| Protection level | IP67 | ||

| Flange standard | HG/T20592-2009, HG/T20615-2009 or according to user requirements | ||

✧FISHER (Fisher) series of intelligent float liquid (boundary) level transmitter

This series of products directly introduce the original FIELDVUE DLC3010 or DLC3100 series of intelligent liquid level controllers. This series of intelligent buoy liquid (boundary) level transmitters output 4-20mA standard DC signal. Through the HART communicator compatible with DLC series intelligent liquid level controllers, the intelligent liquid level controller can be inquired, configured, calibrated or tested , Can also accept the information of a single loop, and can download the information from the scene to the control system. It uses displacement sensor technology to measure the liquid level or the interface level between two liquids. In addition to the normal function of reporting process level PV, the DLC series uses the FOUNDATION Fieldbus protocol, which allows easy access to important information about process operations and can be integrated into new or existing control systems at any time.

Main purpose and scope of application: It is widely used in the measurement of the level, boundary and density of various pressure, high temperature and low temperature liquids in the production process control of petroleum, chemical, metallurgy, electric power and light industry.

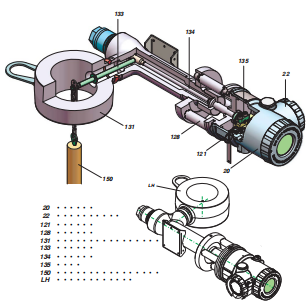

✧FOXBORO (Foxboro) series intelligent float liquid (interface) level transmitter

This level gauge combines the rich experience of FOXBORO and adopts the most advanced digital technology. All the sensors, amplifiers, torque transmission components, watch case components, heat dissipation components and other key components of the meter head of this series of transmitters are original products provided by FOXBORO. The whole machine is delivered according to original standards. The buoyancy of the float is transmitted to the working rod of the sensor through the float rod and the torque tube, and then acts on the free end of the sensor element. Four thin-film metal strain measuring elements are sprayed onto the sensor element, and the resistance changes with tension or pressure. The four thin-film metal strain measuring elements are connected to a Wheatstone bridge powered by an amplifier, and the diagonal bridge voltage proportional to the effective weight is fed back to the electronic amplifier as an input signal. The voltage is converted into a 4-20mA two-wire output signal through an electronic amplifier.

*HART communication, 4 ~ 20mA output

* Measuring point backup

* Physical units such as% and 4-20mA can be displayed on site

* Configuration via FDT-DTM

* Continuous self-test, status and test information

* Easy to adjust the measuring point, without factory calibration

* Process temperature range 196℃~ +500℃

* Multi-language LCD display

* Configurable safety value

* Standard IR communication

*32-point linear volume measurement

* Utilize metal thin film sensor technology

| Classification | encoding rules | illustrate | ||

| series | UTD | Intelligent float level gauge | ||

| brand | Z | kaidi's own brand | kaidi | |

| A | FISHER | Fisher | ||

| B | FOXBORO | Foxboro | ||

| Measurement type | Y | Liquid level | ||

| J | Boundary | |||

| Installation method | C | Side loading | ||

| D | Top loading | |||

| Pressure Level | 1 | PN10 | 2 | CL150LB |

| 1.6 | PN16 | 5 | CL300LB | |

| 2.5 | PN25 | 11 | CL600LB | |

| 4 | PN40 | 15 | CL900LB | |

| 6.3 | PN63 | 26 | CL1500LB | |

| 10 | PN100 | 42 | CL2500LB | |

| 16 | PN160 | |||

| 25 | PN250 | |||

| Range-density | *-* | Unit mm-g/cm3 | * Arabic numerals | |

| Temperature | W1 | <180℃ | ||

| W2 | ≥ 180℃ | |||

| Inner sink material | Ti | titanium | ||

| P | 304 | |||

| PL | 316L | |||

| P1 | 321 | |||

| T | Other material customization | |||

| Explosion-proof form | Omit | no request | ||

| a | Intrinsically safe | |||

| b | Flameproof | |||

| Accessories | Omit | No accessories | ||

| W | With outer float | D | With guide tube | |

| Outer float material | C | Carbon steel | PL | 316L |

| P | 304 | P1 | 321 | |

| Connecting flange | * | Flange diameter | 20,25,32,40,50,65,80,100 | |

| Sealing surface | Omit | Raised face | Suitable for pressure below 10MPa | |

| FF | Full plane | Suitable for atmospheric pressure | ||

| M | Convex | Suitable for matching with concave surface | ||

| FM | Concave | Suitable for matching with convex surface | ||

| RJ | Ring connection surface | Suitable for high pressure | ||

| Keep warm | Omit | No insulation | No insulation requirements omitted | |

| B1 | Type C heating (recommended) | |||

| B2 | Electric heating | |||

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.