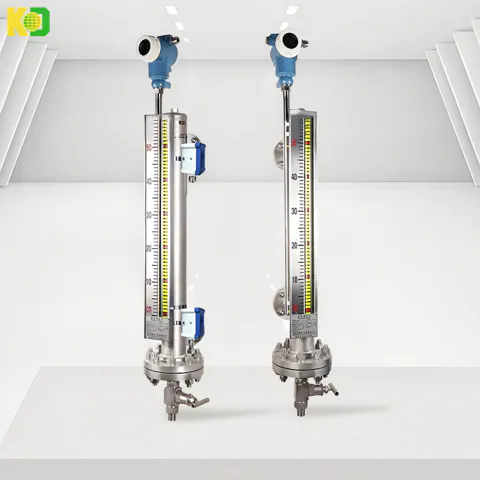

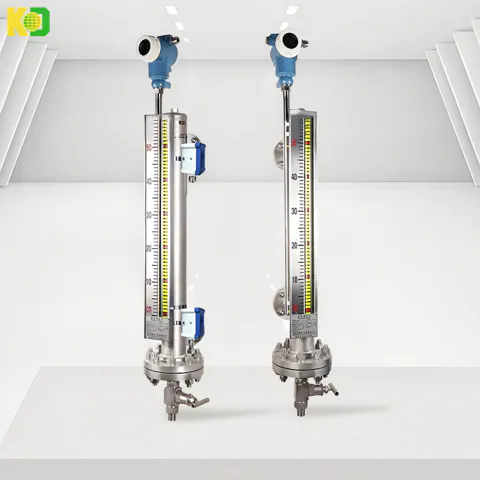

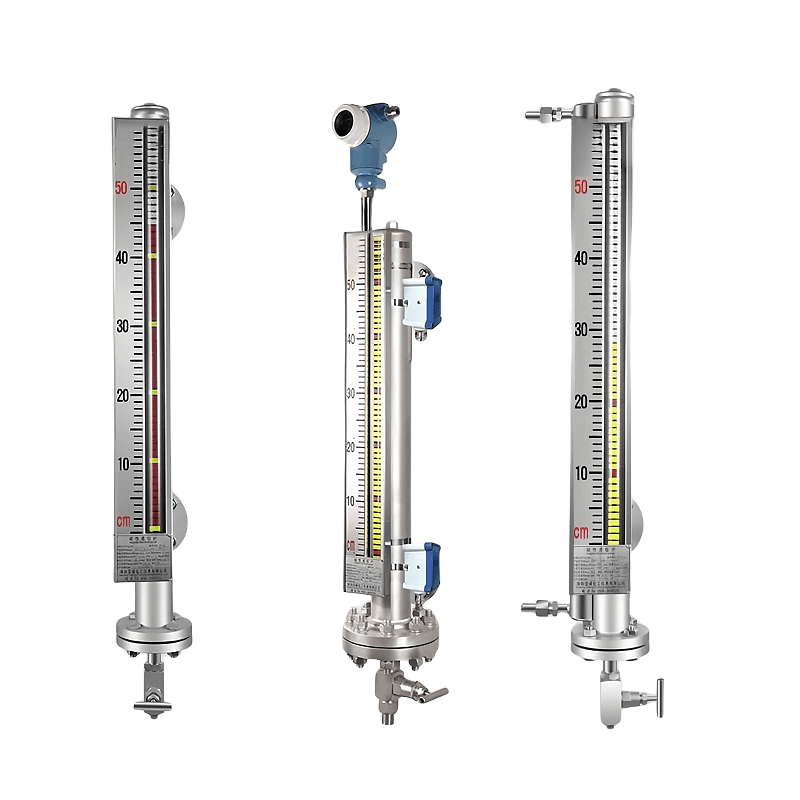

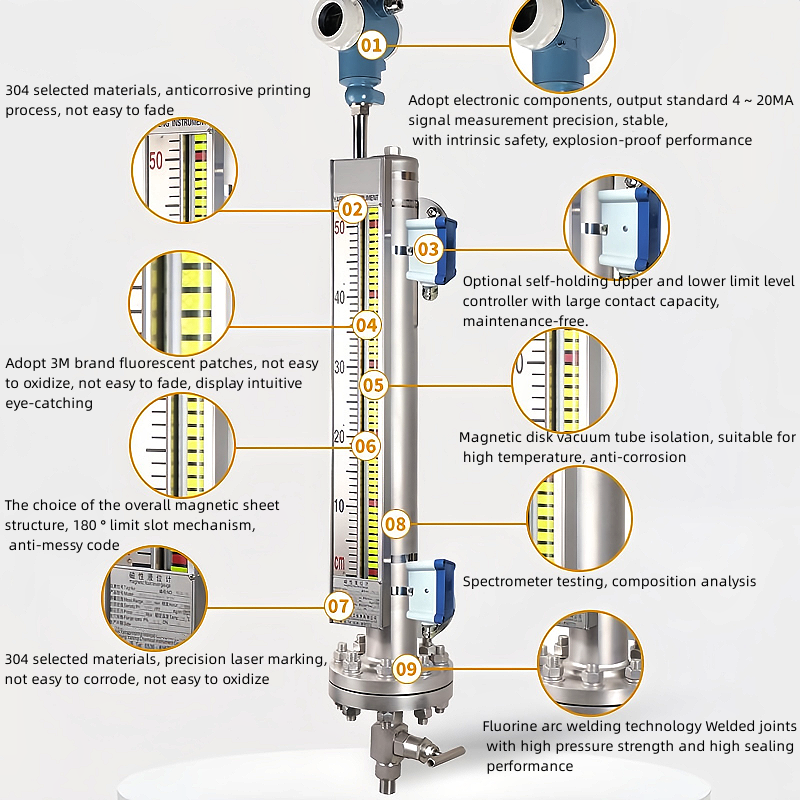

Magnetic level gauge is based on the connecting device principle, buoyancy principle and magnetic coupling principle work. When the liquid level in the vessel under test rises and falls, the float in the chamber of the liquid level gauge rises and falls with the action of buoyancy, and the magnets in the float, through magnetic coupling, are transferred to the on-site indication panel fluorescent flip-flop, when the liquid level rises, the fluorescent surface of the flip-flop turns over, and the flip-flop reverses the non-fluorescent surface when the liquid level falls, and the indicator's yellow-black or red-white intersection, that is, the actual height of the medium liquid level in the vessel (the boundary level), so as to realize the level of the on-site indication. Indication.

Magnetic level gauge and magnetic switch and level transmitter supporting the use of liquid level (boundary level) can realize the upper and lower limits of the alarm and long-distance monitoring and control. It can be widely used in petrochemical, fertilizer, rubber, medicine, ship, military, electric power, food and other industries, all kinds of towers, tanks, tanks, spherical pressure vessels and boilers and other equipment to do the position of the media level indication and automatic control.

| Model | illustrate | |||

| UZ | kaidi Magnetic Level Gauge | |||

| Type of installation | C | Side loading | D | Top loading |

| Panel type | A1 | -40-80℃ normal temperature | Z1 | -190~-20℃ Vacuum |

| A2 | 80-180℃ medium temperature | Z2 | -20-180℃ Vacuum | |

| A3 | 180-350℃ high temperature | Z3 | Vacuum at 180-350℃ | |

| A4 | 350-450℃ ultra high temperature | E | -40℃-450℃ magnetic sensitivity | |

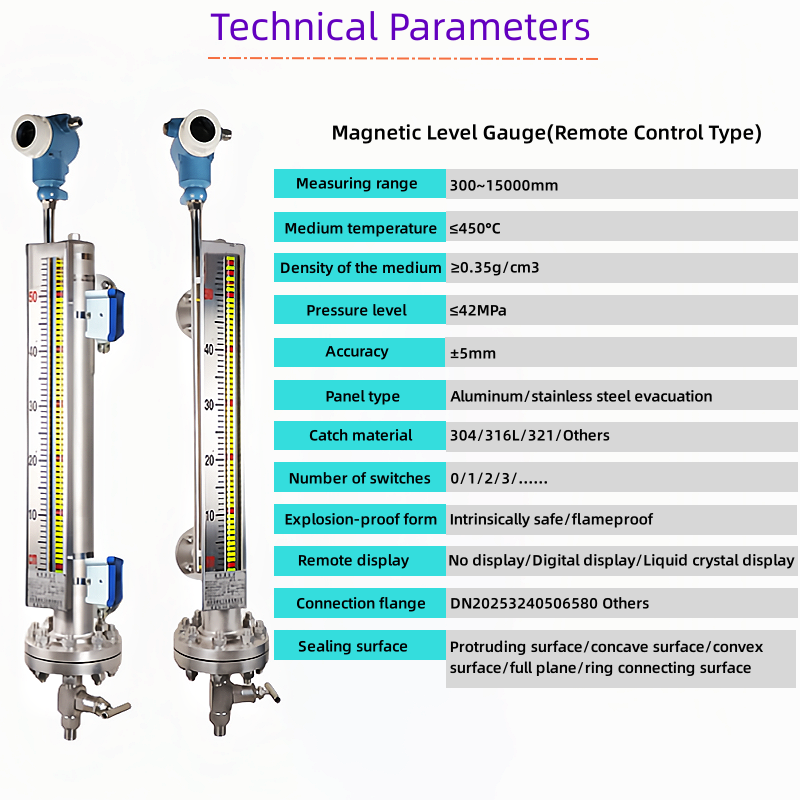

| Pressure Rating (MPa) | 1 | PN1.0 | 2 | CL150LB |

| 1.6 | PN1.6 | 5 | CL300LB | |

| 2.5 | PN2.5 | 11 | CL600LB | |

| 4 | PN4.0 | 15 | CL900LB | |

| 6.3 | PN6.3 | 26 | CL1500LB | |

| 10 | PN10.0 | 42 | CL2500LB | |

| 16 | PN16.0 | |||

| Range-Density | Range mm-density g/cm³ | |||

| Flange Material | P | 304 | PF | 304 lined with fluorine |

| PL | 316L | C | Carbon steel | |

| PP | PP | Ti | titanium | |

| Flange Diameter | 15 | Side mounted DN15 | 50 | Top loading DN50 |

| 20 | Side mounted DN20 | 65 | Top loading DN65 | |

| 25 | Side mounted DN25 | 80 | Top loading DN80 | |

| 32 | Side mounted DN32 | 100 | Top loading DN100 | |

| 40 | Side mounted DN40 | 125 | Top loading DN125 | |

| 50 | Side mounted DN50 | 150 | Top loading DN150 | |

| 65 | Side mounted DN65 | 200 | Top loading DN200 | |

| 80 | Side mounted DN80 | 250 | Top loading DN250 | |

| Flange sealing surface | Omit | Raised face | FM | Concave |

| F | Convex | FF | Full plane | |

| Tube material | P | 304 | P1 | 321 |

| PL | 316L | P4 | 304L | |

| PF | 304 lined with fluorine | Ti | titanium | |

| PP | PP | |||

| Insulation/anti-frost | Omit | No | ||

| C | Type C insulation pipe (recommended) | |||

| T1 | Set vacuum insulation | |||

| T2 | Jacket insulation | |||

| D1 | 40-90 constant temperature electric heating | |||

| D2 | 120°C temperature control adjustable electric heating | |||

| S1 | Anti-frost below -40°C | |||

| S2 | -40~-20℃ anti-frost | |||

| Accessories | Y | Remote transmission level gauge | ||

| K | Alarm switch | |||

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.