The emergence of magnetostrictive level measurement technology is a good solution to the problem of measuring liquid level and interface with high accuracy and reliability. KD8800 series magnetostrictive level (interface) transmitter is an extremely high-precision measurement instrument that can measure liquid level and interface at the same time in most of the working environment conditions.

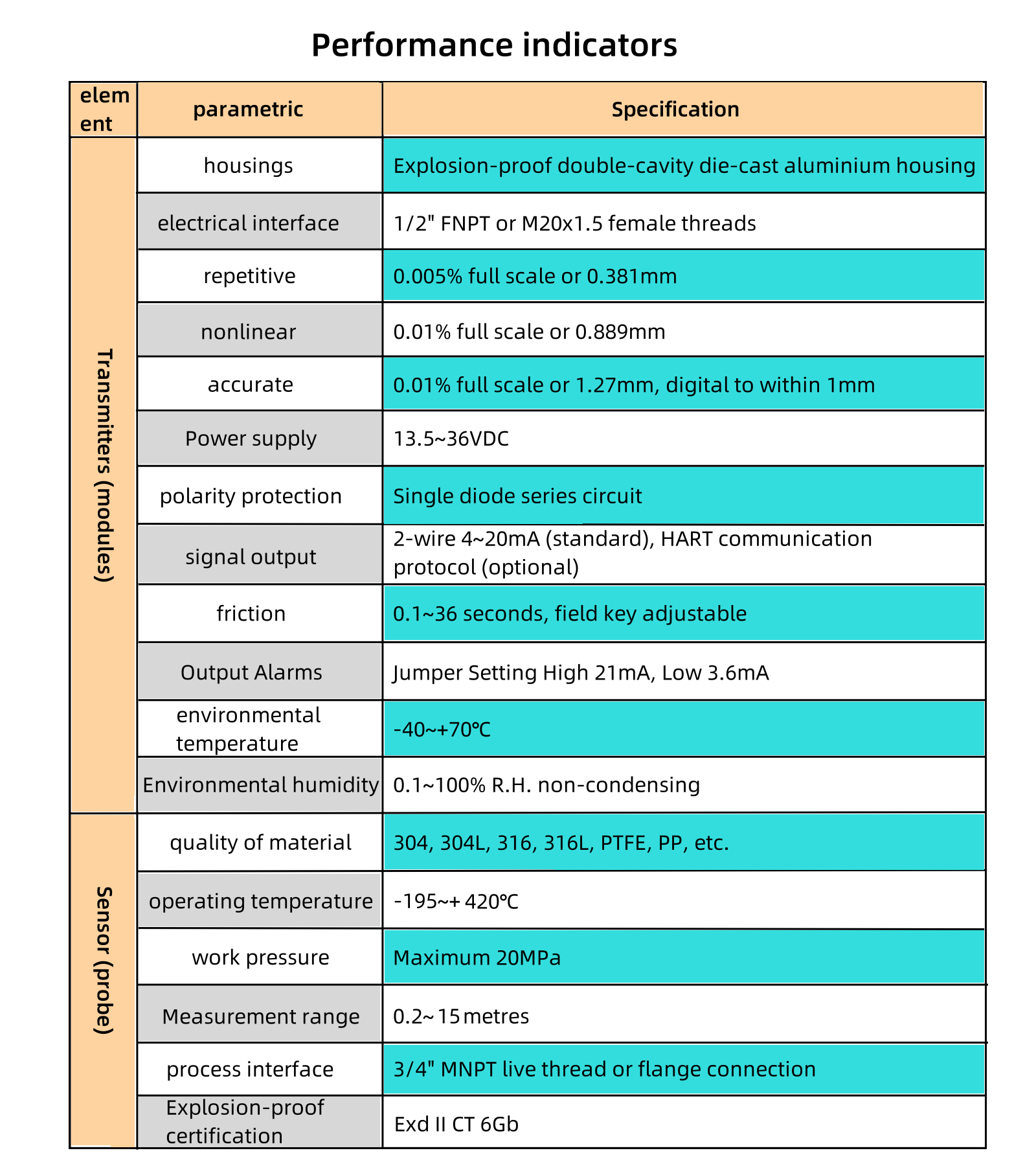

Magnetostrictive level transmitters are widely used in the world for accurate level measurement in process control, with temperature up to 420 ℃ and pressure up to 20MPa optional grade. 4 ~ 20mA analogue and HART (Highway Addressable RemoteTransducer) can be addressed remote sensor high-speed channel of the open communication protocol, so that and most of the control system more convenient digital connection. The KD8800 series of magnetic sensors are available in a wide range of different sizes and grades. Therefore, since the introduction of the KD8800 series magnetostrictive liquid level gauge, it has been widely used in industry, and has gained excellent stability of the measurement effect.

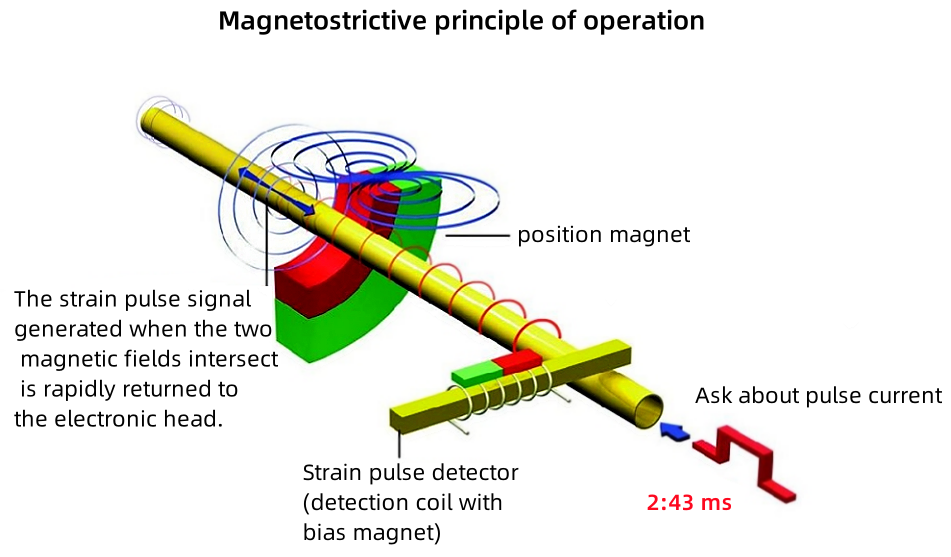

The KD8800 is based on the magnetostrictive principle. Inside the probe there is a magnetostrictive wire that is subjected to a fixed frequency pulse. The pulses and the magnetic field generated by the magnetic float interact to produce an induced wave on the magnetostrictive wire. The induced wave is transmitted at a known speed from the current position of the magnetic float to the electronic compartment of the magnetostrictive wire. The sensors assembled on the transmitter's electronic compartment convert the received wave into an electronic signal which is measured and calculated by an electronic microprocessor device and converted into a 4-20mA signal output proportional to the position of the magnetic float.

▶High accuracy: 0.01% of full scale or 1mm

▶High accuracy: 0.01% of full scale or 1mm

▶Simple calibration: push-button or using HART protocols

▶No need to repeat the calibration, once set up for permanent use

▶Adopting double-cavity structure, electronic components and terminals

are independent double-cavity

▶No drift or error due to changes in the following parameters:

Changes in dielectric constant. Changes in gas-phase composition

▶4~20mA current loop power supply, the maximum length of the probe 22m

▶Total level/interface measurement or total level and interface measurement

at the same time

▶Temperature range:-195~+420°C

▶Field replaceable module, no need to recalibrate after replacement

▶Built-in RFI/EMI filter

▶Digital-analogue dual-signal communication

KD8800 magnetostrictive level (interface) transmitter adopts modular design, simple structure, consists of three parts.

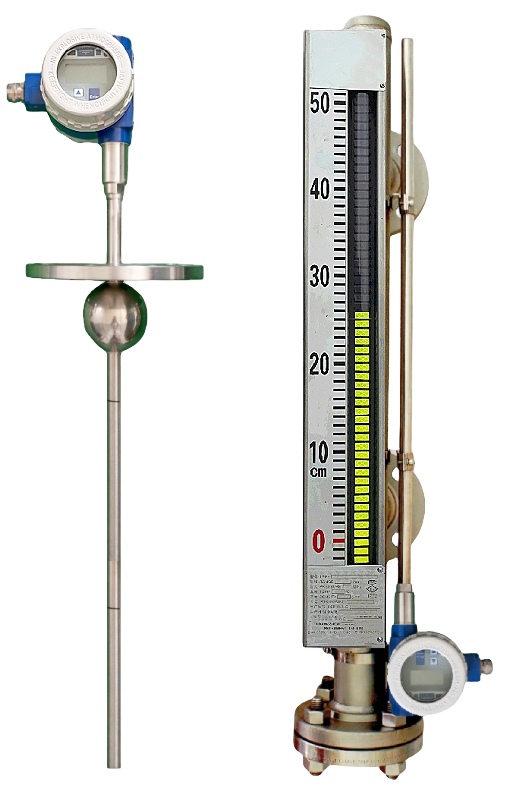

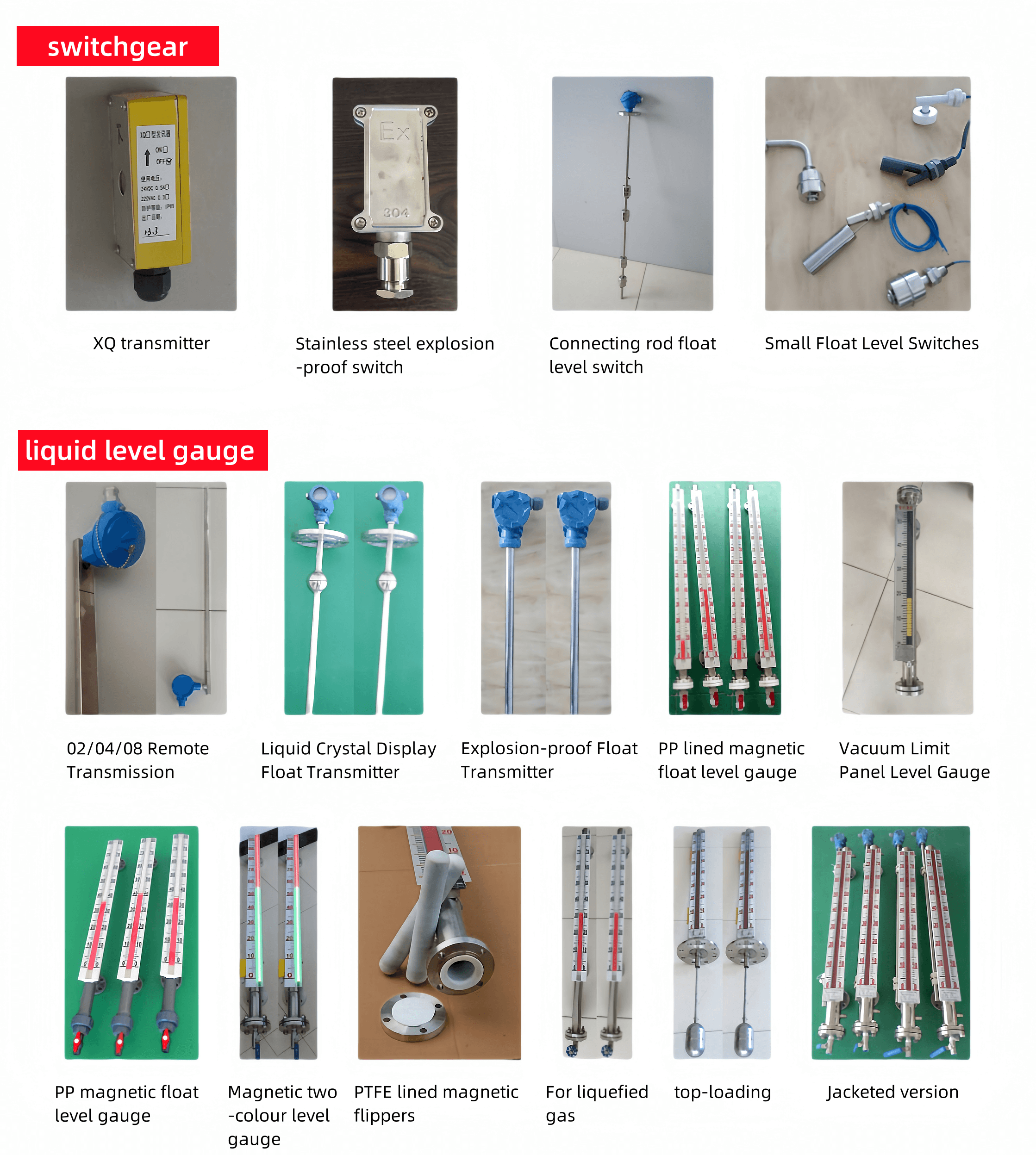

1. Fully intelligent electronic transmitter: Intelligent programming, with liquid crystal display, optional HART communication output.

2. Sensor part: including high sensitivity, large signal range of high-power sensors and long life magnetostrictive signal pulse waveguide.

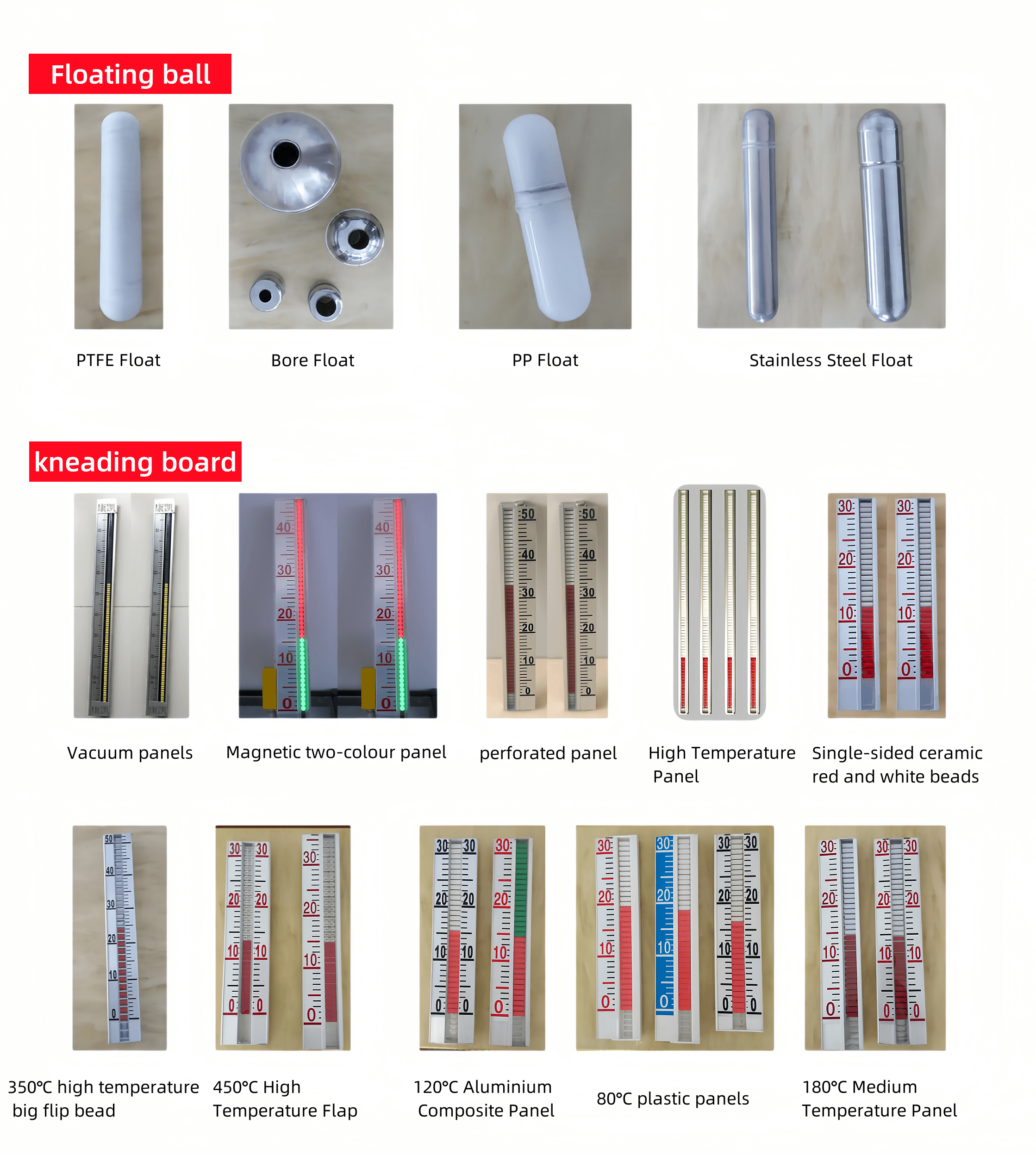

3. Magnetic float: KD8800 magnetostrictive level (interface) transmitter float for the special 360 ° no dead angle, ultra-far magnetic line of magnetic float. High-temperature and high-pressure floats can be selected, and ensure that the float does not demagnetise under high and low temperature environment for a long time.

I. Product overview

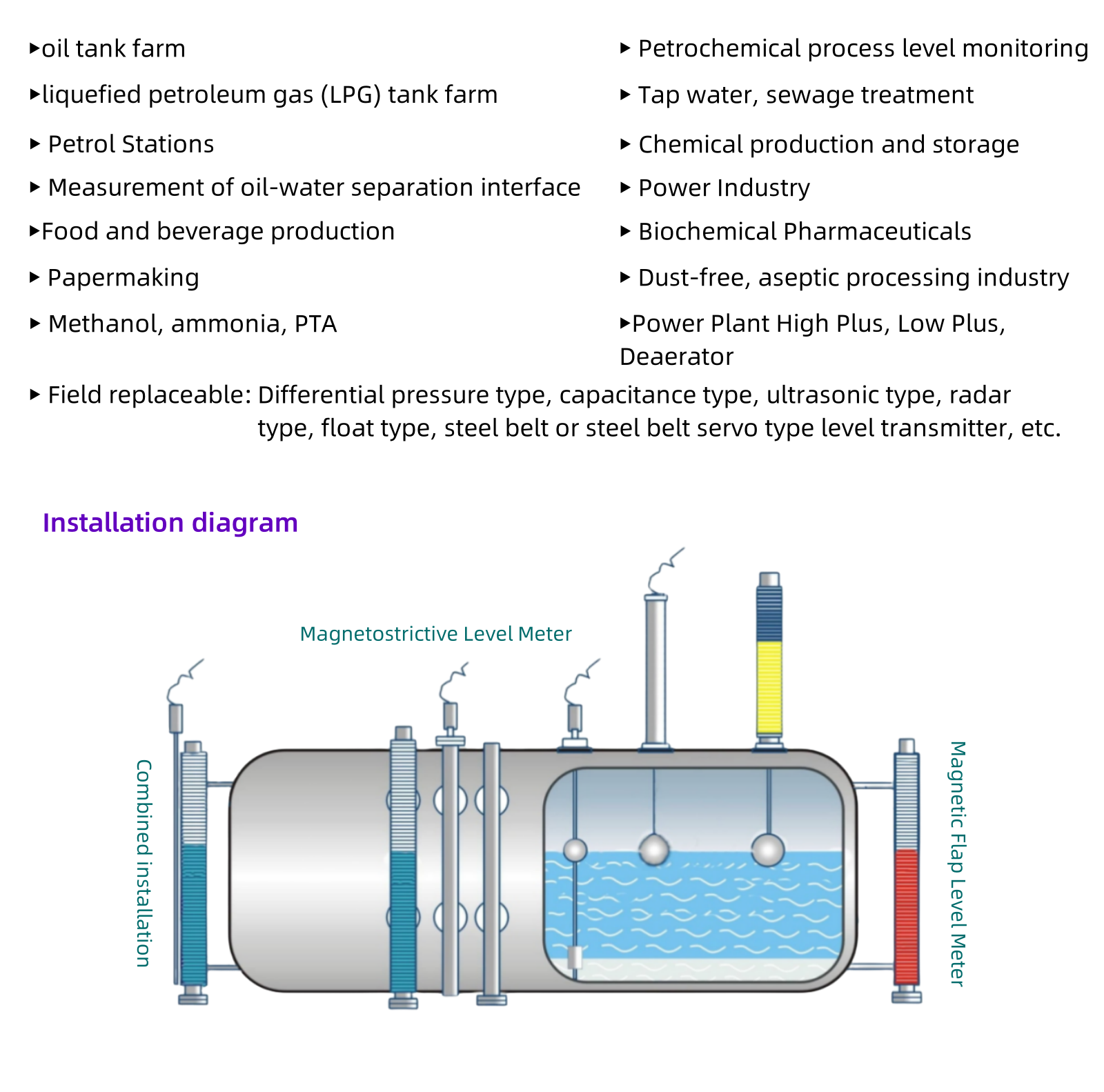

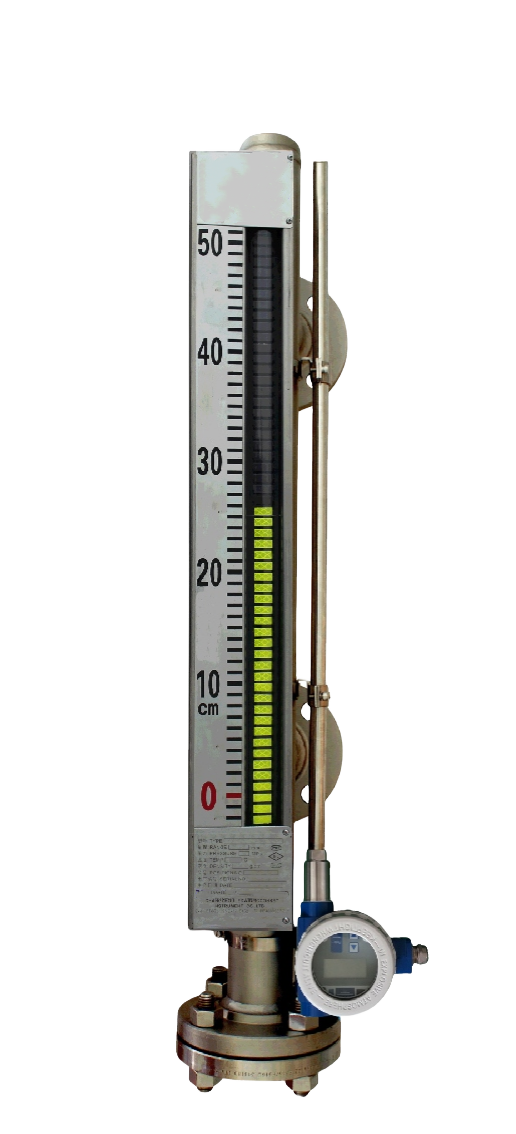

The KD8800C side-mounted magnetostrictive level (interface) transmitter (externally mounted on a magnetically coupled level indicator) is widely used in industry for accurate level measurement of process vessels. High accuracy and maintenance-free are two important reasons for choosing this product. Optional ratings up to 420°C and 20 MPa are available.

The KD8800 Magnetostrictive Level (Interface) Transmitter is suitable for virtually all application conditions.The HART communication protocol option makes it easy to digitally connect the KD8800 to most control systems. The built-in LCD provides 4~20mA, percentage, and other engineering unit displays.

When used on storage tanks, considerations of high accuracy, low maintenance and reasonable overheads motivate users to install a magnetically coupled level indicator with visual indication and connect to a DCS system with the KD8800. The built-in high accuracy processing sensor allows the KD8800 to provide accurate output in horizontal or spherical tanks.

The KD8800 series of magnetostrictive level gauges are used as "float replacements" in dynamic processing. Most float level gauges are repeatedly found to have the following problems in operation: most output errors are caused by changes in specific gravity, leakage from the torsion tube, and process media sticking to the torsion tube and transducer. The new external float (magnetically coupled level indicator) for the KD8800 solves these problems. A huge improvement in accuracy can also be realised. In addition, it is a very convenient way to update the motorised float transmitter.

II. Product overview

Magnetostrictive level gauges can be used for interface measurements.The KD8800 is the best technology available for level interface measurement and control.The KD8800 series can provide two outputs: i) interface; ii) total level. It can be applied to the specific gravity difference down to 0.02. The KK8800 series is commonly used for oil-water interface measurements, and other applications including acid tanks, propane tanks, desalters and sumps.

The non-contact measurement of the KD8800 series can be used as a valve positioner. A magnet is attached to the end of the valve and the KD8800 is placed next to the end of the valve.The high accuracy of 0.01% inherent in the KD8800 transmitter allows it to measure and control the position of the valve better than other products. The KD8800 can also be used as a device positioner. Industrial equipment requires precise positioning of instruments. This can be achieved by magnetostriction (non-contact measurement). It is used in many applications including, gates, skylights, dampers, hydraulic cylinders, etc. The KD8800 has the advantage of a keypad structure, and 4~20mA output, and the complex design structure ensures the user an easy installation and a long service life.KD8800 has the advantage of key structure and 4~20mA output.

Features of the KD8800C side mounted magnetostrictive level (interface) transmitter include: high accuracy 0.01% of full scale; easy push-button calibration; forget-me-not technology (never need to be recalibrated); and is not affected by changes in dielectrics, water vapour compositions, temperatures and pressures.

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.