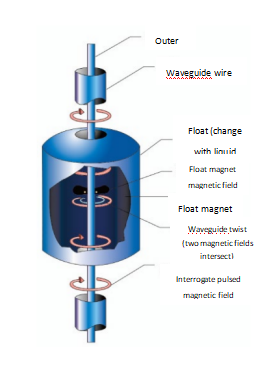

The UCZ magnetostrictive level gauge has the characteristics of high precision, high stability, high reliability, and high cost performance. It can be used in various industrial measurement and control occasions, and can also be used as a measuring instrument. This series of products is a magnetic level gauge sensor with extremely high precision that can continuously measure liquid level and interface, and provide on-site display and analog signal output. The sensing resolution of the traditional reed switch sensor is increased by 10 times. above. The basic structure is composed of three parts: detection rod, circuit sensing element and float. During the measurement, the inductive element of the circuit generates a current pulse, which is transmitted down the probe rod and generates a circular magnetic field. There is a float outside the probe rod, which moves up and down along the probe rod as the liquid level changes. Because the float is equipped with a set of permanent magnets, the float generates a magnetic field at the same time. When the electromagnetic field meets the float's magnetic field, a "twisted" pulse is generated. The time difference between the "twisted" pulse and the float and measure the liquid level. It can also be used in conjunction with the UZ-type magnetic level gauge.

Magnetostrictive level gauge is mainly composed of electronic components, magnetostrictive waveguide wire, float and other parts. During the measurement, the electronic component generates a current "excitation" pulse, the pulse current at the speed of light It runs down the waveguide filament and forms a circumferential ampere-circular magnetic field around the waveguide filament. When the annular magnetic field generated by the excitation pulse current meets the bias magnetic field generated by the permanent magnet in the float, the magnetic field around the float changes, so that the waveguide wire made of magnetostrictive material generates an induced torsional wave at the position of the float Pulse, the torsional wave propagates from the generating point to the two ends of the waveguide wire at the speed of sound, the torsional wave transmitted to the end is absorbed by the damping device, the signal transmitted to the excitation end is received by the detection device, and the pulse current and torsion are measured by the electronic component The time difference of the wave is multiplied by the propagation velocity of the torsion wave in the waveguide wire (the fixed amount is 2800m/s), and the distance between the position where the float generates the torsion wave and the measurement reference point can be accurately calculated, that is, the liquid level Location. The principle of magnetostrictive level gauge sensor is shown on the left.

* It can continuously measure the liquid level or interface of the storage tank.

* The most advanced principle of magnetostriction is adopted.

* The measurement accuracy is extremely high, the error is only 0.01% of the full scale, and the maximum error does not exceed 1mm

* Adapt to high temperature and high pressure working conditions, external binding type: -40~350℃; floating ball insertion type: -40~120℃, the maximum pressure can reach 11.0Mpa.

* It has intrinsic safety and explosion-proof performance and is suitable for use in flammable and explosive places.

* Output standard 4-20mA signal, with Hart protocol communication.

* Installed on the tank top or tank side, integrated installation and maintenance are convenient, and it supports on-site adjustment.

* Can measure liquid level and boundary at the same time

| Nominal pressure | ≤ 11MPa |

| Measuring range | Rigid rod: 300 ~ 6000mm Flexible rod: 5000 ~ 20000mm |

| Probe material | 304, 316, 321, stainless steel lined with PTFE, etc. |

| Measurement accuracy | ±1mm or ±0.3%F·S (current output type) |

| Protection level | IP67 |

| Temperature range | Outside binding type: -40~350℃; floating ball insertion type: -40~120℃ |

| Medium viscosity | ≤ 0.05Pa.s |

| Medium density | ≥ 0.43 g/cm3 |

| Power supply | DC24V |

| Explosion-proof grade | Flameproof type: Exd IICT6 Intrinsically safe type: Exia IIBT6 |

| Nominal diameter | DN50 or according to user requirements. |

| Flange standard | HG/T20592-2009, HG/T20615-2009 or according to user requirements. |

| Classification | Encoding rules | illustrate | ||

| Series | UCZ | Magnetostrictive level gauge | ||

| Form | G | Rigid rod | ||

| R | Flexible rod | |||

| Measurement type | D | Liquid level | Single display | |

| S | Boundary | Dual display | ||

| Pressure Level | 1 | PN10 | ||

| 1.6 | PN16 | 2 | CL150LB | |

| 2.5 | PN25 | 5 | CL300LB | |

| 4 | PN40 | 11 | CL600LB | |

| 6.3 | PN63 | |||

| 10 | PN100 | |||

| Effective insertion depth-range | *-* | Unit mm | * Arabic numerals | |

| -Density- | -*- | Unit g/cm3 | * Arabic numerals | |

| Installation method | Omit | Top mounting flange type | ||

| Y2 | Bundled | |||

| Guide rod material | P | 304 | ||

| PL | 316L | |||

| P1 | 321 | |||

| PF | 304 lined with fluorine | |||

| PCT | 304 Wound PTFE | |||

| Flange specification | * | Flange diameter | 50、65、80、100、125、150 | |

| Sealing surface | Omit | Raised face | Suitable for pressure below 10MPa | |

| FF | Full plane | Suitable for atmospheric pressure | ||

| M | Convex | Suitable for matching with concave surface | ||

| FM | Concave | Suitable for matching with convex surface | ||

| RJ | Ring connection surface | Suitable for high pressure | ||

| Float material | P | 304 | ||

| PL | 316L | |||

| Ti | titanium | |||

| PF | 304 spraying | |||

| TiF | Titanium spray | |||

| Explosion-proof form | Omit | No explosion-proof requirements | ||

| a | Intrinsically safe | |||

| b | Flameproof | |||

| Accessories | Omit | No | ||

| W | With outer float | |||

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.