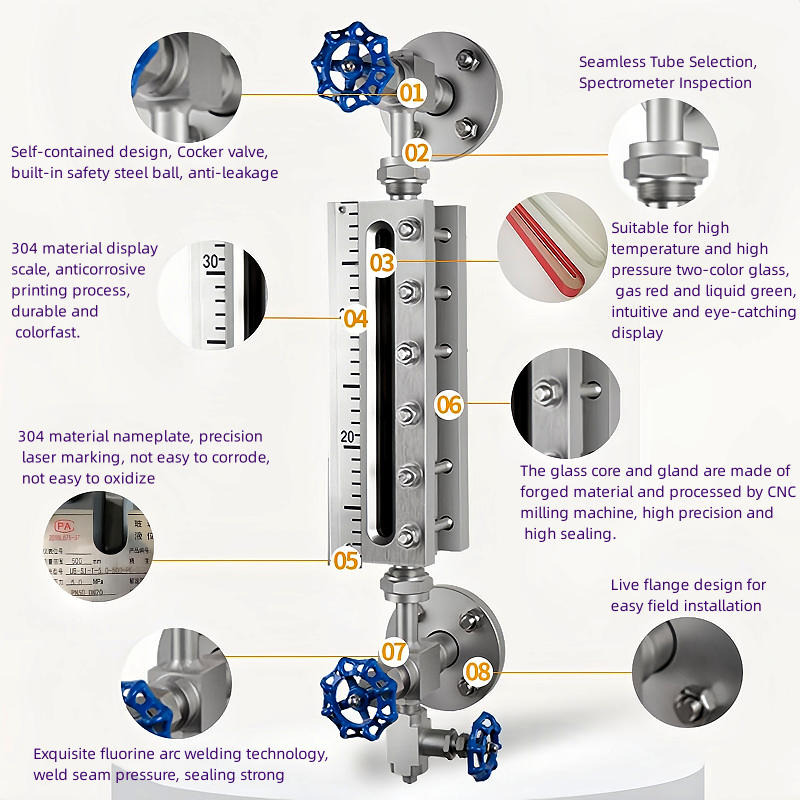

1. Self-closing design (standard):

In order to improve the safety performance of the glass level gauge, this product adopts a special structural design when designing the glass level gauge (valve). , automatically close the liquid flow channel to prevent the medium from continuing to flow out.

2. Heat tracing device (optional)

The heat tracing or cooling device can be customized according to the customer's measurement requirements. There are various types of connection ports, which can be customized according to the form or size of the customer's on-site interface, and there is no need for the customer to change the form or size. When heating, it can be heated by steam or hot water to prevent the medium from freezing or crystallizing when the temperature is too low. During cooling: when the temperature of the measuring medium is too high and gasification is likely to occur, cold water can be introduced for cooling to slow down the gasification of the medium and make the liquid level display more accurate and stable.

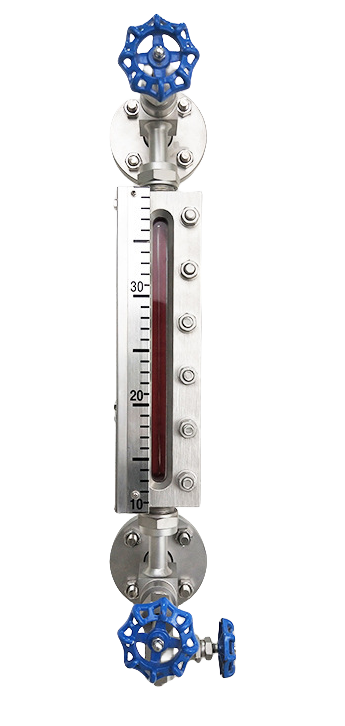

3. Red and green two-color display (optional)

The glass of the glass level gauge is made of high-quality high-pressure glass, which has the characteristics of uniform thickness, high transparency, clear indication, corrosion resistance, high temperature and high pressure resistance, etc. According to the customer's on-site use requirements, special technology and materials can be used, and the liquid level can be displayed in two colors by using the optical principle, making the liquid level display more clear and intuitive.

4. Display the scale ruler (optional)

This product can add a scale scale to the display body part of the glass level gauge according to the needs of customers, so that the glass level gauge can directly read the height of the liquid level scale like a magnetic flip level gauge, which greatly simplifies And facilitate the liquid level measurement process.

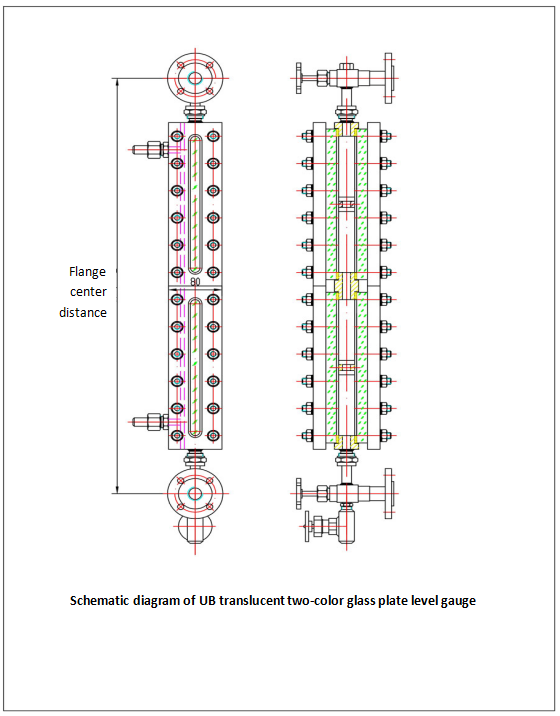

5. No blind area optimization design (optional)

In order to meet the measurement requirements of no blind zone, this product has optimized the design of the traditional basic glass plate level gauge. By moving the connecting pipe upwards, the measurement requirements of no blind zone are achieved.

| Measuring range | (Flange center distance L): 500mm, 800mm, 1100mm, 1400m, 1700mm or according to user requirements; | Visual range | H=L-260; |

| Nominal pressure of level gauge | ≤4.0 MPa | Operating temperature | -20~+250℃ |

| Needle valve automatic closing pressure | ≥0.3MPa | Wetted material | 20, 304, 316 or according to user requirements |

| Non-wetted material | Carbon steel | Heated steam jacket joint | R3/8 (external thread) or according to user requirements |

| Heating steam pressure | ≤1 MPa | Connecting flange | HG/T20592-2009, HG/T20615-2009 or according to user requirements |

| Product parameter | ||||

| Model | illustrate | |||

| UB | KD two-color glass disc level meter | |||

| Category | Omit | Cork | 3T | Three-way |

| D | Chase Sutra | |||

| Display category | S1 | monochrome | S2 | Two-color |

| Type | F | Reflective | T | Transmissive |

| Pressure rating (MPa) | 1.6 | PN1.6 | 6.3 | PN6.3 |

| 2 | CL150LB | 10 | PN10.0 | |

| 2.5 | PN2.5 | 11 | CL600LB | |

| 4 | PN4.0 | 15 | CL900LB | |

| 5 | CL300LB | 16 | PN16.0 | |

| Range | Range mm | |||

| Material | CC | Whole carbon steel | ||

| PP | Overall 304 | |||

| PC | Wetted 304, gland carbon steel | |||

| PLC | Wetted 316/321, gland carbon steel | |||

| PLP | Wetted 316/321, gland 304 | |||

| PLPL | Wetted 316/321, gland 316 | |||

| Flange specification | 15 | DN15 | 40 | DN40 |

| 20 | DN20 | 50 | DN50 | |

| 25 | DN25 | 65 | DN65 | |

| 32 | DN32 | FF | Full plane | |

| Flange sealing surface | Omit | Raised face | RJ | Ring connection surface |

| M | Convex | |||

| FM | Concave | |||

| Keep warm | Omit | No | ||

| B | carry | |||

| Temperature | W2 | 0-250 | ||

| W4 | 0-400 | |||

| W5 | 0-500 | |||

| Glass material | GH | Tempering (pressure ≤ 4.0MPa, temperature ≤ 250℃) | ||

| GP | High borosilicate (pressure ≤ 8.0MPa, temperature ≤ 400℃) | |||

| LG1 | Aluminum silicon 1 (pressure ≤ 16.0MPa, temperature ≤ 500℃) | |||

| LG2 | Aluminum silicon 2 (pressure ≤ 20.0MPa, temperature ≤ 500℃) | |||

| LG3 | Aluminum silicon 3 (pressure ≤ 25.0MPa, temperature ≤ 500℃) | |||

| Blind spot requirements | Omit | No | ||

| A | Normal no blind zone | |||

| B | Single row interleaving | |||

| S | Double row interleaving | |||

| Anti-frost | Omit | No | ||

| F | With anti-frost | |||

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.