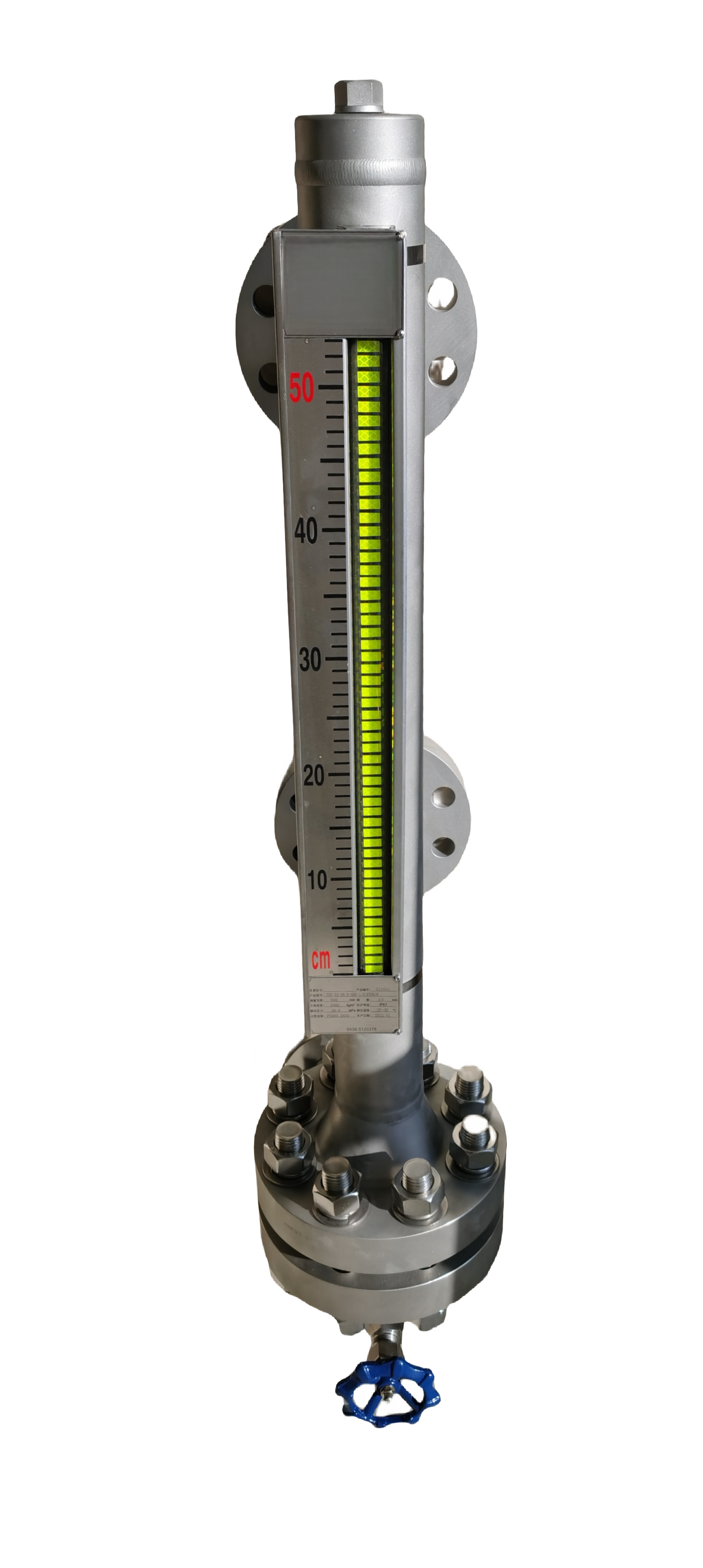

UZC type high temperature and high pressure magnetic level gauge is a series of level gauges specially designed by our company for high temperature and high pressure measurement environment. Magnetic level gauge is based on the connecting device principle, buoyancy principle and magnetic coupling principle work. When the liquid level in the measured vessel rises and falls, the float in the liquid level gauge chamber rises and falls with the buoyancy force, and the magnets inside the float are transferred to the fluorescent flip-flop on the field indication panel through magnetic coupling. When the liquid level rises, the flip-flop fluorescent surface flip, when the liquid level falls flip-flop non-fluorescent surface reversal, the indicator of the yellow-black or red-white junction, that is, the actual height of the medium level in the container (boundary level), so as to realize the level of the field indication. High-temperature and high-pressure magnetic flip-flop level meter is suitable for high-temperature and high-pressure liquid vessel level boundary level measurement and control, clearly indicates the height of the liquid level, intuitive and eye-catching display, the indicator is completely isolated from the tank, safe to use, reasonable design, simple structure, easy installation, stable reliability and long service life.

✱The wall thickness simulation design software independently developed according to the pressure vessel design standard can scientifically design the wall thickness of the pressure chamber of the product and the specifications and dimensions of the floating ball according to the pressure and temperature range of the customer's working conditions, effectively improving The pressure-bearing performance and safety performance of this series of products.

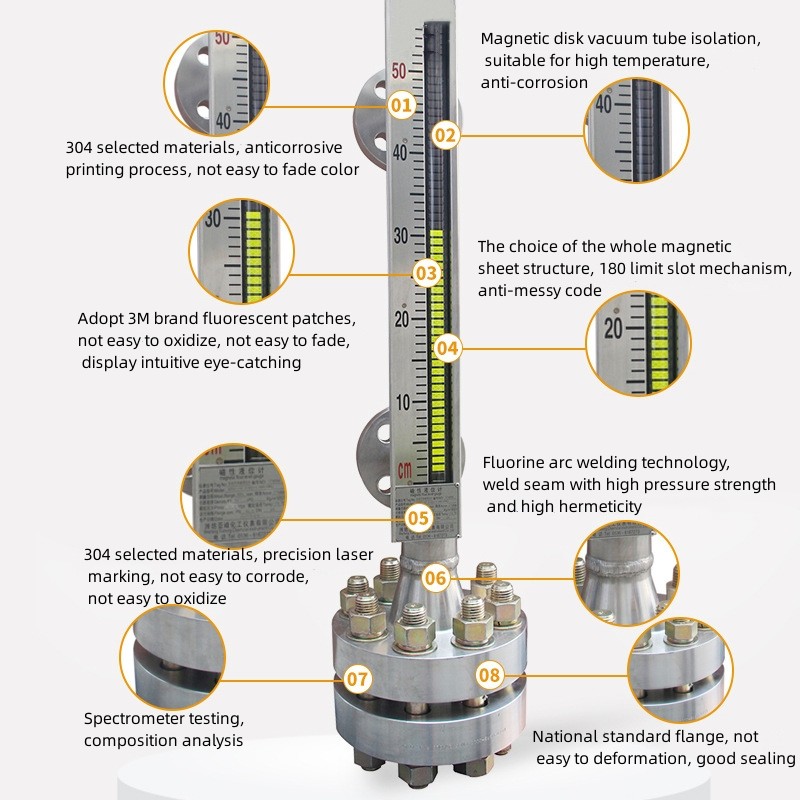

✱ The pressure-bearing chamber and the floating ball adopt the single-sided welding and double-sided forming process, which effectively guarantees the quality of the welding seam.

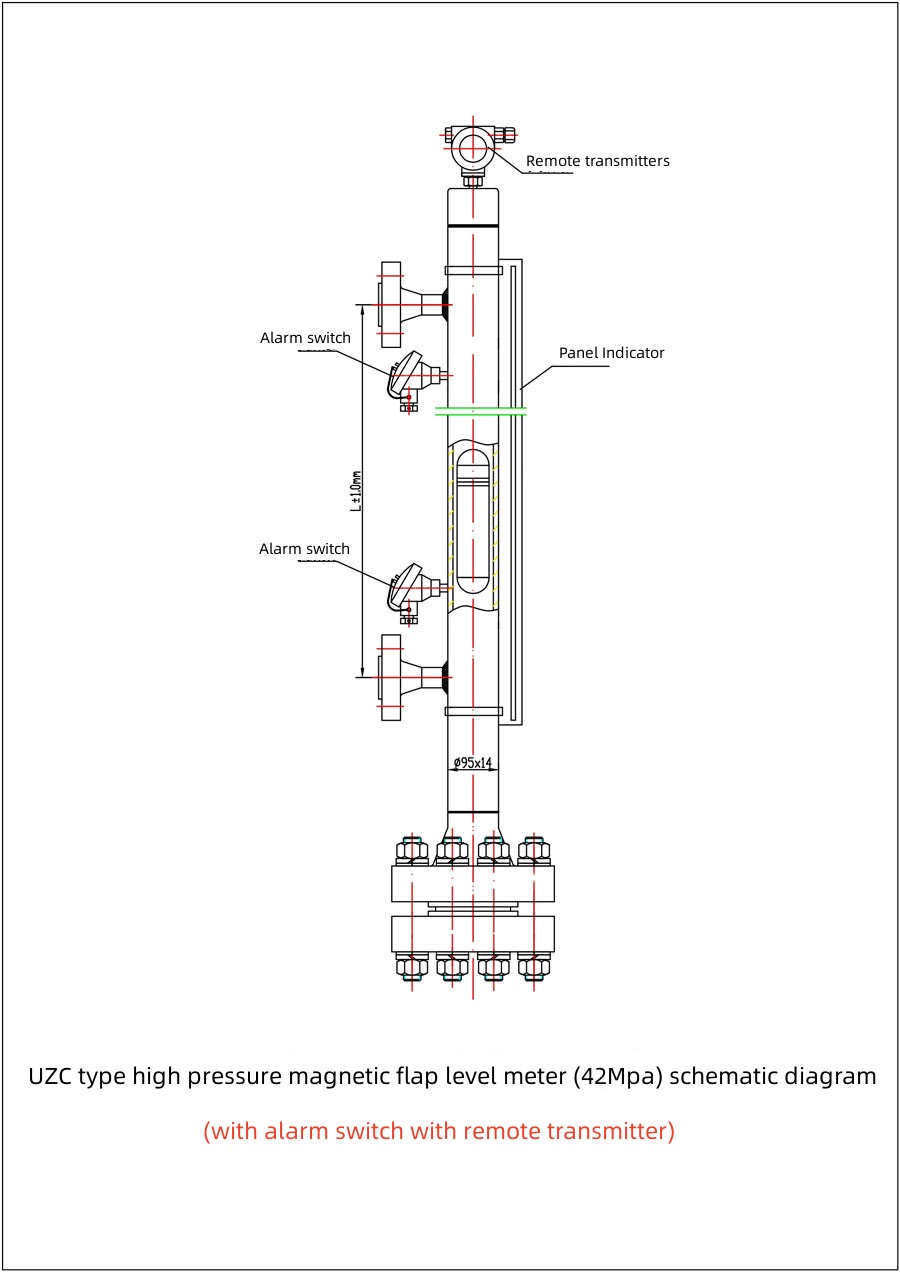

✱ For different pressure levels, the flange connection sealing surface of this product adopts high pressure design. When the connecting flange sealing surface adopts the RJ ring connection surface, the maximum design pressure can reach 42MPa.

✱ Flaw detection and inspection: This series of products will perform a series of flaw detection and inspection on the parts and chambers after welding according to different pressure levels to ensure the quality of the weld and zero defects of the material to the greatest extent.

✱The display panel adopts high temperature isolation technology for high temperature environment, which can effectively isolate the display panel from the high temperature chamber at high temperature, which improves the temperature resistance performance and service life of this product, and the maximum temperature resistance can reach 450 ℃.

✱ Water pressure test: After the production is completed, this product will be subjected to a rigorous high-pressure water pressure simulation experiment. The high-pressure water pressure holding test is 1.25-1.5 times of the customer's site design pressure, which is higher than the customer's site use pressure. The water pressure test simulates the customer's on-site use pressure, guarantees the safety performance and sealing performance of this series of products to the greatest extent, and provides the safest and most reliable products for customers' safe production measurement.

| Measuring Range | 300- 15000mm | Rated Temperature | ≤450℃ |

| Measurement Accuracy | ±5mm | Medium Viscosity | ≤0.02Pa.S . |

| Nominal Pressure | ≤42MPa | Following Speed | ≤0.08m/s |

| Medium Density | ≥0.35g/cm3 | Transmission Output | Two-wire 4-20mA, DC600Ω load |

| Medium Density Difference | ≥0.03g/cm3 (measurement interface) | Connection Flange Size | HG/T20592-20635-2009, DN20, PN2.5 If other flanges are used, please indicate when ordering |

| Model | illustrate | |||

| UZ | Kaidi Magnetic Level Gauge | |||

| Type of installation | C | Side loading | D | Top loading |

| Panel type | A1 | -40-80℃ normal temperature | Z1 | -190~-20℃ Vacuum |

| A2 | 80-180℃ medium temperature | Z2 | -20-180℃ Vacuum | |

| A3 | 180-350℃ high temperature | Z3 | Vacuum at 180-350℃ | |

| A4 | 350-450℃ ultra high temperature | E | -40℃-450℃ magnetic sensitivity | |

| Pressure Rating (MPa) | 1 | PN1.0 | 2 | CL150LB |

| 1.6 | PN1.6 | 5 | CL300LB | |

| 2.5 | PN2.5 | 11 | CL600LB | |

| 4 | PN4.0 | 15 | CL900LB | |

| 6.3 | PN6.3 | 26 | CL1500LB | |

| 10 | PN10.0 | 42 | CL2500LB | |

| 16 | PN16.0 | |||

| Range-Density | Range mm-density g/cm³ | |||

| Flange Material | P | 304 | PF | 304 lined with fluorine |

| PL | 316L | C | Carbon steel | |

| PP | PP | Ti | titanium | |

| Flange Diameter | 15 | Side mounted DN15 | 50 | Top loading DN50 |

| 20 | Side mounted DN20 | 65 | Top loading DN65 | |

| 25 | Side mounted DN25 | 80 | Top loading DN80 | |

| 32 | Side mounted DN32 | 100 | Top loading DN100 | |

| 40 | Side mounted DN40 | 125 | Top loading DN125 | |

| 50 | Side mounted DN50 | 150 | Top loading DN150 | |

| 65 | Side mounted DN65 | 200 | Top loading DN200 | |

| 80 | Side mounted DN80 | 250 | Top loading DN250 | |

| Flange sealing surface | Omit | Raised face | FM | Concave |

| F | Convex | FF | Full plane | |

| Tube material | P | 304 | P1 | 321 |

| PL | 316L | P4 | 304L | |

| PF | 304 lined with fluorine | Ti | titanium | |

| PP | PP | |||

| Insulation/anti-frost | Omit | No | ||

| C | Type C insulation pipe (recommended) | |||

| T1 | Set vacuum insulation | |||

| T2 | Jacket insulation | |||

| D1 | 40-90 constant temperature electric heating | |||

| D2 | 120°C temperature control adjustable electric heating | |||

| S1 | Anti-frost below -40°C | |||

| S2 | -40~-20℃ anti-frost | |||

| Accessories | Y | Remote transmission level gauge | ||

| K | Alarm switch | |||

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.