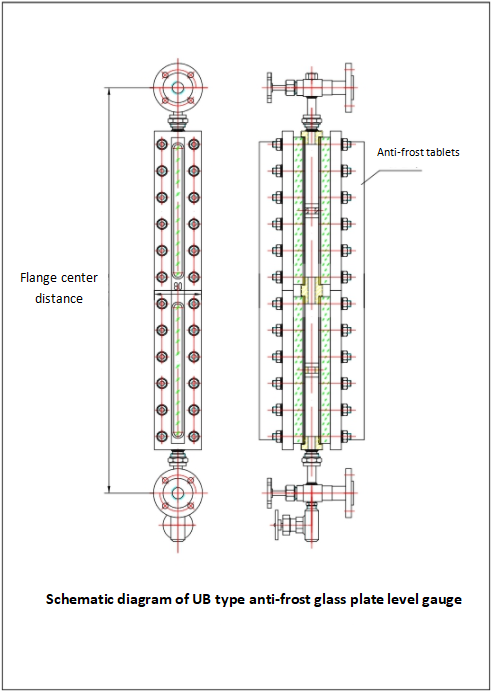

A liquid level indicator designed for cryogenic equipment in the petroleum industry. In the liquid level measurement, the low temperature (below 0℃) medium can make the surface of the container frost, so that the frost layer covers the surface of the container, so it is not feasible to measure the liquid level of the low temperature medium with a general glass plate level gauge. The anti-frost glass plate level gauge designed by our company can clearly observe the liquid level of the measured medium through the anti-frost fins. The anti-frost glass plate level gauge not only uses the principle of the glass plate level gauge connector, but also solves the problem of anti-frost based on the principle of temperature gradient in physics. That is, when a material with a transfer temperature contacts a low-temperature source, the farther away from the low-temperature source, the closer its temperature is to the ambient temperature, which solves the problem of liquid level reading. The transparent plexiglass fins installed on the anti-frost glass plate level gauge are set based on this principle, so the actual liquid level of the container can be seen on the transparent plexiglass fins.

◐Measuring range (installation center distance L): 580mm, 920m, 1260mm, 1600mm, 1940mm;

◐Visual range: H=L-300;

◐Nominal pressure: ≤4.0 MPa;

◐Working temperature: -160~0℃;

◐Needle valve automatic closing pressure: ≥0.3MPa;

◐Flushing and sewage outlet: M12×1.25 (internal thread);

◐Connecting flange: HG/T20592-2009, HG/T20615-2009 or according to user requirements

| Visual range | H=L-300 | Nominal pressure | ≤4.0 MPa |

| Operating temperature | -160~0℃ | Needle valve automatic closing pressure | ≥0.3MPa |

| Flushing, sewage outlet | M12×1.25 (internal thread) | Connecting flange | HG/T20592-2009, HG/T20615-2009 or according to user requirements |

| The main technical parameters | Measuring range (installation center distance L): 580mm, 920m, 1260mm, 1600mm, 1940mm | ||

| Model | illustrate | |||

| UB | Kaidi glass plate level gauge | |||

| Category | Omit | Cork | 3T | Three-way |

| D | Chase Sutra | |||

| Display category | S1 | monochrome | S2 | Two-color |

| Type | F | Reflective | T | Transmissive |

| Pressure rating (MPa) | 1.6 | PN1.6 | 6.3 | PN6.3 |

| 2 | CL150LB | 10 | PN10.0 | |

| 2.5 | PN2.5 | 11 | CL600LB | |

| 4 | PN4.0 | 15 | CL900LB | |

| 5 | CL300LB | 16 | PN16.0 | |

| Range | Range mm | |||

| Material | CC | Whole carbon steel | ||

| PP | Overall 304 | |||

| PC | Wetted 304, gland carbon steel | |||

| PLC | Wetted 316/321, gland carbon steel | |||

| PLP | Wetted 316/321, gland 304 | |||

| PLPL | Wetted 316/321, gland 316 | |||

| Flange specification | 15 | DN15 | 40 | DN40 |

| 20 | DN20 | 50 | DN50 | |

| 25 | DN25 | 65 | DN65 | |

| 32 | DN32 | FF | Full plane | |

| Flange sealing surface | Omit | Raised face | RJ | Ring connection surface |

| M | Convex | |||

| FM | Concave | |||

| Keep warm | Omit | No | ||

| B | carry | |||

| Temperature | W2 | 0-250 | ||

| W4 | 0-400 | |||

| W5 | 0-500 | |||

| Glass material | GH | Tempering (pressure ≤ 4.0MPa, temperature ≤ 250℃) | ||

| GP | High borosilicate (pressure ≤ 8.0MPa, temperature ≤ 400℃) | |||

| LG1 | Aluminum silicon 1 (pressure ≤ 16.0MPa, temperature ≤ 500℃) | |||

| LG2 | Aluminum silicon 2 (pressure ≤ 20.0MPa, temperature ≤ 500℃) | |||

| LG3 | Aluminum silicon 3 (pressure ≤ 25.0MPa, temperature ≤ 500℃) | |||

| Blind spot requirements | Omit | No | ||

| A | Normal no blind zone | |||

| B | Single row interleaving | |||

| S | Double row interleaving | |||

| Anti-frost | Omit | No | ||

| F | With anti-frost | |||

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.