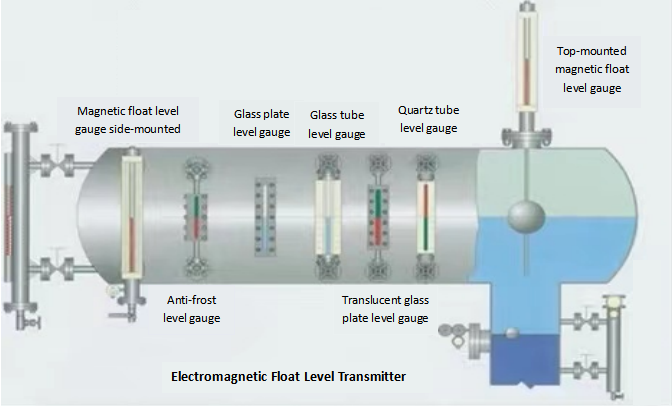

The top-mounted magnetic flap level gauge is directly installed on the top of the container, and the magnetic link is driven up and down by the floating ball with the up and down movement of the liquid level (or interface). The magnetic steel in the magnetic link uses the principle of magnetic coupling to drive the magnetic flip. The board indicator uses red and blue (liquid red and gas blue) to clearly and intuitively indicate the liquid level or boundary level in the process container, which can be transmitted over a long distance and realize automatic control. UFDZ series top-mounted magnetic flap level gauges are mainly composed of the body part, on-site indicator, remote transmitter and upper and lower limit alarms.

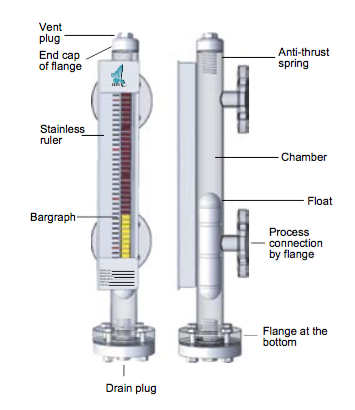

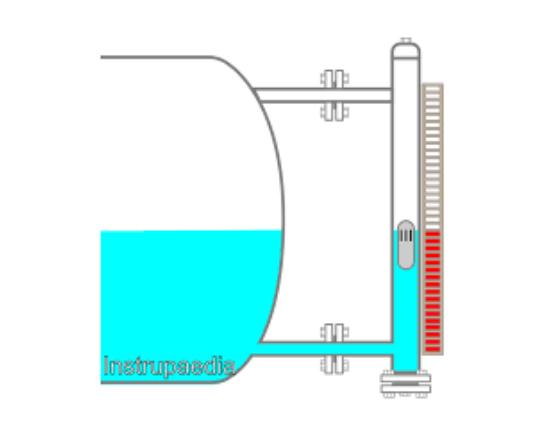

The level gauge is developed based on the principle of buoyancy and magnetic coupling. When the liquid level in the container under test rises and falls, the magnetic float in the body tube of the level gauge also rises and falls, and the magnetic steel in the float is transferred to the magnetic turning column indicator through magnetic coupling, driving the red and white turning columns to turn 180° , When the liquid level rises, the turning column turns from white to red, when the liquid level drops, the turning column turns from red to white. The red and white junction of the indicator is the actual height of the liquid level inside the container, so as to achieve a clear indication of the liquid level.

| Measuring range | 0-4000mm |

| Nominal pressure | 1.0MPa;1.6MPa;2.5MPa;4.0MPa |

| Nominal diameter | DN150 |

| Working temperature | -40℃~120℃ |

| Medium density | Liquid level:ρ≥0.5.g/cm³ |

| Boundary:ρ1-ρ2≥0.25g/cm³ | |

| Wetted material | 1Cr18Ni9Ti |

| Flange standard | JB82-59(Level gauge flange: flat or raised face flange) |

| Heat tracing jacket joint | ZG1/2’’ (internal thread) |

| Upper and lower limit alarm | Output signal: One normally open, two normally closed (or two normally open, two normally closed, please specify when ordering) |

| Ambient temperature | -20℃~40℃ |

| Measurement accuracy | ±10mm |

| Life span | ≥105 |

| Protection level | IP65 |

| Power inlet | M20*1.5 (internal thread) |

| Explosion-proof mark | Flameproof:dIIBT4 |

| Essential type:iaIICT5 |

The basic level gauge is based on the principle of buoyancy. The float moves up and down with the rise and fall of the liquid level in the measuring tube. The magnetic steel in the float drives the red and white turning columns to turn over 180 degrees through magnetic coupling. When the liquid level rises, the turning column turns from white to red, and when it falls, it turns from red to white, thereby realizing the indication of the liquid level.

Upper and lower limit switch output The magnetic float is used to move with the liquid level to make the reed switch installed at the setting position of the liquid level gauge riser actuate to realize ON-OFF control or alarm.

Electric remote transmission Install the transmitter on the magnetic float level gauge. The transmitter is composed of a sensor and a converter. It moves up and down through the magnetic float, and causes the measurement parts in the catheter to act sequentially through magnetic coupling to obtain the resistance signal change and convert it into a 0~10mA or 4~20mA standard current signal Output so as to connect with digital display instrument or computer to realize remote display.

The product consists of a main body (composed of upper and lower ducts), a flap box (composed of red and white two-color magnetic flaps), a float (composed of magnets, ejector rods, and pontoons). Its structure is shown in the figure. The working principle is: the pontoon in the container (developed according to different media and pressures), floats up and down with the change of the liquid level in the downcomer, and the magnet moves up and down in the upper duct through the ejector rod, which promotes the flipping of the outer flap And use red and white colors to indicate the height of the liquid level.

①This type of level gauge can be installed on the upper or lower part of the container when opening holes on the side of the container are not suitable and there is little space around the container

②Suitable for liquid medium with high viscosity

③The viewing direction of the display can be changed arbitrarily

④Other features are the same as those of UFZ

◑The protective pipe of the level gauge and the main pipe must be kept vertical

◑The connecting rod cannot be bent and must be inserted straight

◑After installation, the turning column of the display needs to be guided once with magnetic steel to make it display white above zero and red below zero.

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.