1.Product Features

Intelligent transmitter, through the customized highly integrated SoC system level processor, accurately collects the voltage signal from the pressure sensor, converts it to standard analog DC4 ~ 20mA current signal with high accuracy for remote transmission, and stably displays the measured value. It is a high performance system that integrates pressure measurement, analog transmission

output and on-site display as one of the high-precision products.

Intelligent menu, simple interface, make production easier and more efficient. System-level processor makes the product more stable and reliable.

0.45mA high stability and low temperature drift constant current output for diffusion silicon pressure sensor.

Diffusion Silicon Pressure Sensor.

There is also a constant pressure source output for ceramic pressure sensors.

Up to 11 points calibration, perfect linearization, so that the product accuracy is higher. SPN parameter multi-range selection, support 士15mV-土500mV wide range input.

Arbitrarily set the output range of the transmitter, convenient for field modification of the transmitter output range. Output range is convenient to modify the transmitter on site.

2 .Main Parameters

Power supply: DC12 ~30V (24V recommended)

Power supply: DC12 ~30V (24V recommended)

Measurement accuracy: +0.2%FS, +0.5%FS

Power consumption: ≤3.85mA

Signal Fan Park: DC 0- 500mV (special signals can be customized)

Output Signal: 2-wire 4 20mA (24V, with load capacity 500Ω).

(Voltage output 0~10V, 0~5V, 1~5V can be customized)

Sampling rate: 5 times per second

Display range: -1999 ~ 9999

Temperature drift: 60PPm/C

Operating Temperature: -10~ 50C

Relative Humidity: ≤85%RH, no strong corrosive gas

Dimension: 54x54x26

Sensor diaphragm: 316 stainless steel

Contact media connection: stainless steel

Pressure range: -100kpa-0-100Mpa

(Customized according to customer's range)

Medium temperature: - -40- -85C

Explosion-proof grade: Exdll CT6 (customized)

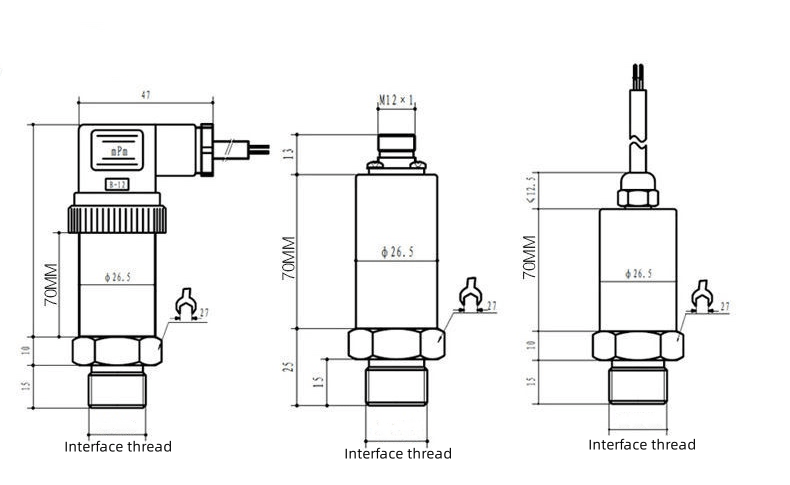

3. Structural dimensions

4. Installation matters

①Select a place for installation that is easy to operate and maintain.

② Installation should be as far away as possible from the source of vibration

③Install it as far away as possible from the heat source; ④Install it directly on the pipeline or equipment.

④Install directly on the pipeline or equipment, and use a wrench to

Clamp the transmitter in the hexagonal position.

5.Precautions

① Be careful when handling and installing the transmitter to avoid impacting the circuit performance.

avoid impacting the performance of the circuit.

②There is an isolation diaphragm in the pressure inlet of the transmitter, do not touch it with foreign objects.

Do not touch the diaphragm inside the inlet port of the transmitter with foreign objects.

③The outer thread of the transmitter should be sealed carefully, otherwise it will cause unstable pressure.

The pressure is not allowed to be unstable.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist