UQD series intelligent large float level transmitter is the third-generation upgraded product of electric float level gauge. On the basis of the original two generations of liquid level transmitters, it has the advantages of product maintenance, instrument sensitivity, and high temperature resistance. , Sealing reliability has been greatly improved and improved.

This series of products are mainly based on the principle of Archimedes buoyancy. When the liquid level rises and falls, the large floating ball floating on the liquid level of the measuring medium is subjected to buoyancy, and will float up and down with the rise and fall of the liquid level, driving the driven connection mechanism The angle is changed to convert the liquid level change into an angle change, and the angle change is converted into a liquid level change through a high-precision angle sensor and an analog signal is output. In order to improve the sensitivity of the product, a set of lever counterweight counterweights is designed. The number and position of the counterweights can be adjusted externally according to changes in density and range, so as to balance the buoyancy of the float, the gravity of the float, and the gravity of the connecting rod. And the purpose of the friction between the connecting shafts, effectively improving the sensitivity and stability of the product. The head part of the transmitter is separated from the measuring mechanism, which improves the explosion-proof level and makes the measurement safer and more accurate. The transmitter converts the analog voltage signal into a 4-20mA two-wire current output signal, and is loaded with HART protocol communication. It can realize the functions of remote configuration, monitoring, maintenance, and calibration of the instrument, and can constitute a production process measurement, supervision and management system. It is especially suitable for continuous measurement of the liquid level of hot heavy oil (temperature ≤ 450°C, pressure ≤ 6.3MPa), viscous dirty media, asphalt, grease and other oils, as well as flammable, explosive, and corrosive media in oil refineries. It can be widely used in petroleum, chemical industry, metallurgy, medicine and other industrial fields, and it is an ideal liquid level instrument in production process control.

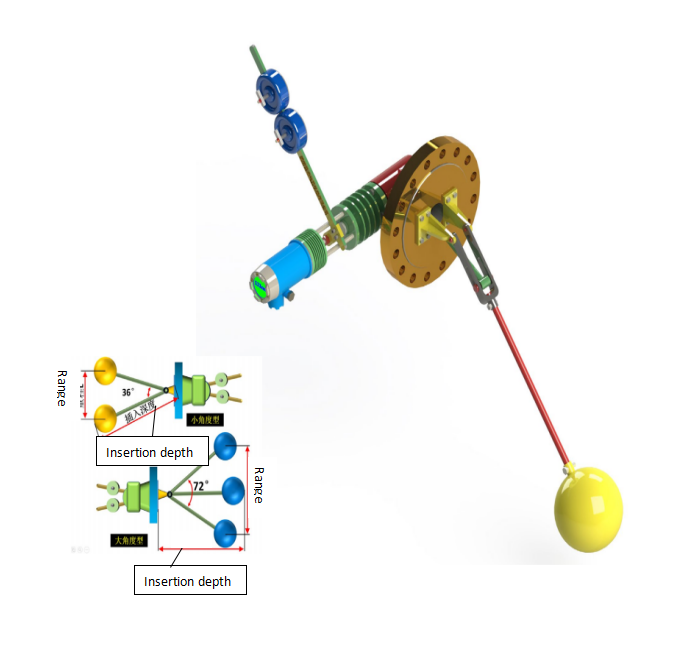

UQD Intelligent Large Float Ball Liquid Level Transmitter is mainly composed of two parts: measuring sensing mechanism and intelligent transmitter. The measuring sensor element is a spherical floating ball. The transmitter uses a balance bar, a balance hammer and a floating ball to form a moment balance mechanism, so the floating ball can freely rise and fall with changes in liquid level. According to different structural characteristics, it can be divided into UQD-1 small corner type and UQD-2 large corner type. When the liquid level changes, the position of the floating ball changes accordingly, driving the main shaft to rotate. The main shaft is connected to the output shaft of the meter head (indicator) angular displacement sensor. The angular displacement sensor converts the floating ball into corresponding changes with the liquid level. The electric signal of the float controller is converted into a standard current signal proportional to the change of the liquid level by the circuit inside the float controller.

| voltage | 24V DC | Nominal pressure | ≤ 6.3MPa |

| Output | 4 ~ 20mA superimposed HART communication | Nominal diameter | DN250 |

| Load Resistance | 230 ~ 1100Ω | Accuracy class | Class 1.0; Class 1.5 |

| Damping time selection | 0 ~ 32 seconds | Medium density | ≥ 0.55/cm3 |

| Operating temperature | -40℃≤ T ≤ 500℃ | Ambient temperature | - 30℃~ 70℃ |

| Measuring range | 400 ~ 1200mm (small corner type); 550 ~ 1600mm (large corner type) | ||

| Flange standard | HG/T20592-2009, HG/T20615-2009 or according to user requirements | ||

| Power inlet | M20X1.5 (inside) or according to user requirements | ||

| Protection level | IP67 | ||

| Diagnosis function | When the instrument fails, output the alarm current | ||

| Configuration function | Configuration of engineering unit, range, display, measurement type, medium density, float height, alarm, etc. | ||

| Alarm function | The upper and lower alarm limits can be set. Output 3.8mA below the lower limit; output 22mA above the upper limit | ||

| Monitoring dynamic variable function | Liquid level/boundary level, percentage, output current, etc. | ||

| Upper and lower limit calibration | Two-point calibration function to achieve fine adjustment of zero point and full scale | ||

| Fixed-point fine-tuning | Migrate at any point to realize the translation function | ||

| In-place configuration function | Configure engineering units, range, display, damping, density, etc. and have data recovery functions | ||

| LCD display function | With backlight, with symbols, 5-digit LCD display, can display various engineering units | ||

| Power failure protection | Yes | ||

| Model | illustrate | |||

| UQD | Kaidi Intelligent Large Float Level Transmitter | |||

| Type | 1 | Small corner | 2 | Big corner |

| Flange diameter | 250 | DN250 | XXX | DNXXX |

| Pressure Level | 2.5 | PN25 | 2 | Class 150 |

| 4 | PN40 | 5 | Class 300 | |

| 6.3 | PN63 | |||

| Range | -XXX | Unit mm | ||

| Density | -XXX | Unit g/cm3 | ||

| Flange material | C | Carbon steel | P | 304 |

| PL | 316L | P1 | 321 | |

| T | Other material | |||

| Flange sealing surface | Omit | RF | F | Convex |

| FM | Concave | FF | Full plane | |

| Float material | P | 304 | PL | 316L |

| P1 | 321 | T | Other material | |

| Explosion-proof grade | Omit | No explosion-proof requirements | ||

| a | Intrinsically safe | b | Flameproof | |

Application examples:

Intelligent large floating ball liquid level transmitter, large angle type, measuring range 1200mm, medium density 0.8g/cm3, flange 304, floating ball material 316L, pressure rating 4.0MPa, flange sealing surface raised face, explosion-proof rating type.

Model: UQD-2-250-4.0-1200-0.8-PPLb

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.