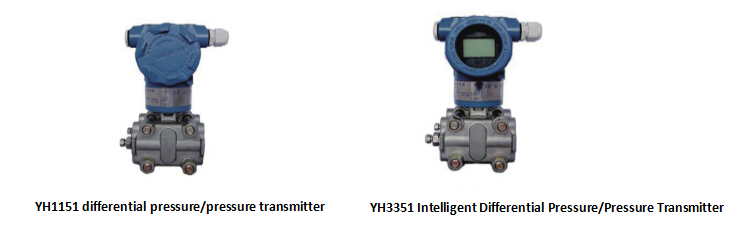

The key raw materials, components and parts of the YH1151/3351 differential pressure/pressure transmitter are all imported or produced by joint ventures, and the whole machine has been strictly assembled and tested. The product has the characteristics of advanced design principles, complete varieties and specifications, and easy installation and use. Because the appearance of this model completely integrates the structural advantages of the two most popular and widely used transmitters (Rosemount 3051 and Yokogawa EJA), it gives users a refreshing feeling and has a strong Versatility and substitution capabilities. In order to be suitable for the continuous improvement and development of the domestic automation level, this series of products not only has a small and exquisite design, but also has an intelligent function with HART fieldbus protocol.

1. Super measurement performance, used for differential pressure, pressure, liquid level, flow measurement;

2. High precision: digital precision + (-) 0.05%; analog precision + (-) 0.5% ~ + (-) 0.1% F·S;

3. The range and zero point are continuously adjustable externally, with a range ratio of 100:1;

4. Positive migration can reach 500%, negative migration can reach 600%;

5. Good stable performance, stability: 0.25% for 60 months;

6. Withstand overvoltage;

7. Solid sensor design;

8. The whole series has a unified structure and strong interchangeability;

9. Diaphragm material that contacts the medium is optional;

10. Low-pressure cast aluminum alloy shell;

11. Measuring rate: 0.2S

12. Miniaturization, all stainless steel flange, easy to install;

13. The process connection is compatible with other products to achieve the best measurement;

14. Smart transmitter with 16-bit computer;

15. Standard 4-20mA, with digital signal based on HART protocol, remote control;

16. Support the upgrade to fieldbus and technology based on field control

1. Use object: liquid, gas or steam

2. Output signal: 4~20mADC. (Specially available for four-wire 200V AC power supply and 0-10mA DC output)

3. Power supply voltage: 12-36V DC, standard value 24VDC;

4. Ambient temperature: -25~70℃ (general transmitter), -15~70℃ (with on-site indicator)

5. Measuring temperature: -40-104℃, flange filled with silicone oil -40-104℃, filled with high temperature silicone oil 15-315℃;

6. Storage temperature: -40~100℃;

7. Relative temperature: 0-100%RH;

8. Protection level: dⅡBT4, iaⅡCT5;

9. Power influence: less than ±0.005%/V of the output range;

10. Vibration influence: 200Hz vibration in any direction, the error caused is 0.05%/g of the maximum range;

11. Influence of installation position: When the working diaphragm is not installed vertically, a zero error of not more than 0.24Pa may occur, and the error may be over-adjusted

The zero position is used to eliminate, which will affect the range;

12. Stability: the accuracy of the transmitter is not exceeded within six months;

13. Indicator: linear indication 0~100%; 3-1/2 digit LCD liquid crystal display;

14. Range and zero position: externally continuously adjustable;

15. Positive and negative migration: the maximum positive migration is 500%, and the maximum negative migration is 600%;

16. Material isolation diaphragm: 316L stainless steel, Hastelloy-C, Monel, tantalum;

Exhaust/drain valve: 316L stainless steel, Hastelloy-C, Monel;

Flanges and joints: 316L stainless steel, Hastelloy-C, Monel;

"O" ring: fluorine rubber; filling liquid; silicone oil inert oil; bolt: 316L stainless steel; electronic housing: low copper aluminum alloy

| YH1151/3351 pressure/differential pressure transmitter | illustrate | ||||

| Measuring range | 2 | 0~0.125-1.5 KPa | |||

| 3 | 0~1.3-7.5 KPa | ||||

| 4 | 0~6.2-37.4 KPa | ||||

| 5 | 0~31.1-186.8 KPa | ||||

| 6 | 0~117-690 KPa | ||||

| 7 | 0~345-2068 KPa | ||||

| 8 | 0~1170-6890 KPa | ||||

| 9 | 0~3450-20680 KPa | ||||

| 0 | 0~6890-41370 KPa | ||||

| Output | E | 4-20mADC | |||

| F | Smart Hart Protocol | ||||

| J | 4-20mADC is the square root of the input pressure | ||||

| Wetted parts material | Flange joint | Exhaust/drain valve | Isolation diaphragm | Filling with liquid | |

| 22 | 316 stainless steel | 316 stainless steel | 316 stainless steel | Silicone oil | |

| 23 | 316 stainless steel | 316 stainless steel | Hastelloy C | ||

| 24 | 316 stainless steel | 316 stainless steel | Monel | ||

| 25 | 316 stainless steel | 316 stainless steel | Tantalum | ||

| 33 | Hastelloy C | Hastelloy C | Hastelloy C | ||

| 35 | Hastelloy C | Hastelloy C | Tantalum | ||

| 44 | Monel | Monel | Monel | ||

| Additional features | M1 | 0-100% linear indicator | |||

| M2 | 0-100% square root indicator | ||||

| M3 | 31/2 LCD digital display | ||||

| Without head | |||||

| B1 | Pipe-mounted bend mounting plate | ||||

| B2 | Board-mounted curved mounting plate | ||||

| B3 | Tube mounted flat mounting plate | ||||

| Without mounting plate | |||||

| D1 | The drain valve is in the upper part of the pressure chamber | ||||

| D2 | The drain valve is in the lower part of the pressure chamber | ||||

| C1 | Weld on the back of 1/2-14NPT pressure connector! 14 Pressure tube | ||||

| C2 | M20×1.5 T-shaped male threaded connector | ||||

| C3 | M20×1.5 T-shaped male thread connection block plus T-shaped connector | ||||

| C4 | 1/2-14NPT taper pipe female thread connector | ||||

| d | Flameproof ExdⅡBT4 | ||||

| i | Intrinsically safe type iaⅡCT6 | ||||

| Static pressure 1MPa | |||||

| Static pressure 4MPa | |||||

| H1 | Static pressure 10MPa | ||||

| H2 | Static pressure1 4MPa | ||||

| H3 | Static pressure 25MPa | ||||

| H4 | Static pressure 32MPa | ||||

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.