Intelligent pressure transmitter is a new type of intelligent instrument jointly developed by our company using international advanced technology and cooperating with domestic technical forces. The instrument adopts microprocessor technology for temperature compensation and nonlinear compensation, which greatly improves the measurement accuracy of the instrument, improves the temperature and thermal performance, expands the range ratio, and adds intelligent configuration functions, which further meets the requirements of high reliability and high performance of industrial field instruments. Stability requirements. The key components and parts are imported, and the whole machine leaves the factory after strict testing. Reliable product quality, complete varieties and specifications, easy to install and use.

▲Water pressure and air pressure measurement

▲Flue and flue gas measurement

▲Petroleum/Petrochemical/Chemical

▲Electricity/City Gas

▲Environmentally friendly exhaust gas treatment

◐During the operation of the instrument, the instrument can be configured in real time, such as modifying the range, monitoring variables, etc.

◐The pressure signal can be intelligently linearized to keep the measurement data accurate and reliable.

◐There are reverse protection circuits and current limiting circuits on the circuit board to avoid accidental damage to the circuit as much as possible.

◐The configured parameters are stored in EPROM and can remain unchanged.

◐High precision and high reliability.

◐Solid components, plug-gable electronic circuit boards, robust against vibration.

◐Explosion-proof structure, all-weather use.

◐Span, zero point and damping are continuously adjustable on site.

◐The indicating mechanism is completely isolated from the measured medium, with good sealing performance, high reliability and safe use.

◐The high-quality sensor has high sensitivity and fast response speed, accurately reflects the subtle changes of flowing or static liquid level, and has high measurement accuracy.

◐The direct-mounted pressure transmitter has a large measuring range and is not limited by the height of the storage tank.

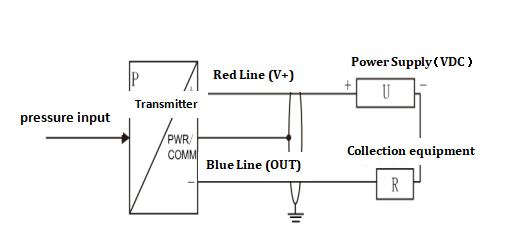

Output signal: DC4-20mA+HART protocol

Output mode: linear output

Square root output (remotely adjustable via configuration software)

Measuring range:

Zero and Span: It can be adjusted with the Span and Zero buttons of the machine, or remotely with the HART handheld smart terminal.

Positive and negative zero-point migration: when the zero-point is negatively shifted, the lower limit of the range must be > or =-URL; when the zero-point is shifted, the upper limit of the range must be < or =+URL. Inspection range must be > or = small range.

Damping time constant: The time constant is adjustable, in increments of 0.1 seconds, from as small as 32 seconds, if the damping time is 0, the default is 0.1.

Ambient temperature limit:-40~85℃(standard type) -20~70℃(LCD Head)

Process Temperature Limits:-40~104℃

Storage Temperature Limits:-40~85℃

Ambient humidity: 0-95% relative humidity

Volume change: <0.01lin³(4px)³ (zero reference calibration range, under reference conditions, silicone oil filling, built-in 316L stainless steel isolation diaphragm)

Accuracy:<5:1≤±0.1%FS ≥5:1≤±0.25%FS

Stability: 6 months, ±0.5% URL

Ambient temperature influence: -29~85℃

Zero point error: 0.5%URL/56℃

Overall error: (0.5%URL+0.2% calibration range)/56℃

Protection class: IP65

Vibration effect: On any axis, the vibration effect is 0.2% URL/g at 200Hz

Power supply range:12~36VDC

Intrinsically safe explosion-proof:Ex ia IIC T6 Ga

Note: Intrinsic safety must be powered by a safety barrier or an intrinsically safe power supply

Influence of installation position: zero drift is at most ±0.25KPa. All zero drifts can be corrected; no effect on range.

Load Effect: No load effect unless there is a change in supply voltage.

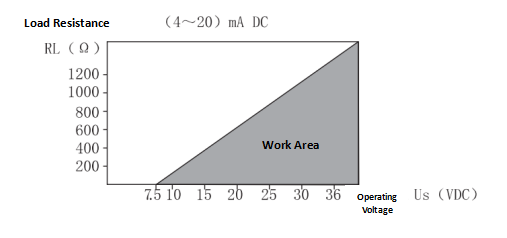

Load characteristics: current type load≤{(Us-12)/0.02(Us=supply voltage)}Ω

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.