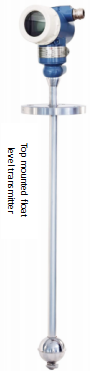

UQZ floating ball liquid level transmitter is the company's technical research and development personnel fully learn from similar products at home and abroad, actively absorb and combine the advantages of many similar products, through continuous and bold improvements, carefully designed on the basis of the original product structure. This product adopts permanent magnet steel and imported electronic components, so that the product has the advantages of simple structure, convenient use, stable performance, long service life, and easy installation and maintenance. This product is almost suitable for liquid level measurement and control in various industrial automation process control, and can be widely used in liquids in the fields of petroleum, food, chemical, water treatment, pharmaceuticals, electric power, paper making, metallurgy, ships and steel furnaces. Position measurement, control and monitoring.

The product is mainly composed of four parts: housing, sensor circuit, converter circuit and display meter. When the magnetic ball with permanent magnet in the cylinder moves up and down with the rise and fall of the liquid level, it will drive the resistance value in the sensor circuit to change linearly, and then the resistance value change will be converted into a 4-20mA standard DC signal through the converter circuit. It is displayed by the display meter and then output to the control room through the output terminal to realize the remote monitoring and control of the liquid level.

| Nominal pressure | ≤ 11MPa |

| Measuring range | 200-8000mm |

| Probe material | 304, 316, 321, PP, stainless steel lined with PTFE, etc. |

| Measurement accuracy | ±5mm |

| Output signal | 4 ~ 20mADC OR 4 ~ 20mADC+HART |

| Protection level | IP67 |

| Temperature range | -20 ~ 80℃ |

| Medium viscosity | ≤ 0.05Pa.s |

| Medium density | ≥ 0.43 g/cm3 |

| Power supply | DC24V |

| Explosion-proof grade | Flameproof type: Exd IIBT6 Intrinsically safe type: Exia IICT6 |

| Classification | Encoding rules | illustrate | ||

| Series | UQK | Float level controller | ||

| Installation form | 1 | Side mounting is not adjustable | ||

| 2 | Side mounted adjustable | |||

| 3 | Adjustable top loading | |||

| Pressure Level | 1 | PN10 | 2 | CL150LB |

| 1.6 | PN16 | 5 | CL300LB | |

| 2.5 | PN25 | |||

| 4 | PN40 | |||

| 6.3 | PN63 | |||

| Effective insertion depth | *-* | Unit mm | * Arabic numerals | |

| -Density- | -*- | Unit g/cm3 | * Arabic numerals | |

| Flange material | P | 304 | PP | PP |

| PL | 316L | PF | 304 lined with fluorine | |

| P1 | 321 | PCT | 304 Wound PTFE | |

| Flange specification | * | Flange diameter | 50、65、80、100、125、150 | |

| Sealing surface | Omit | Raised face | Suitable for pressure below 10MPa | |

| FF | Full plane | Suitable for atmospheric pressure | ||

| M | Convex | Suitable for matching with concave surface | ||

| FM | Concave | Suitable for matching with convex surface | ||

| Float material | P | 304 | PP | PP |

| PL | 316L | PF | 304 spraying | |

| Ti | titanium | TiF | Titanium spray | |

| Explosion-proof form | Omit | No explosion-proof requirements | ||

| b | Flameproof | |||

| Self-check function | Omit | No | ||

| J | With self-check function | |||

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.