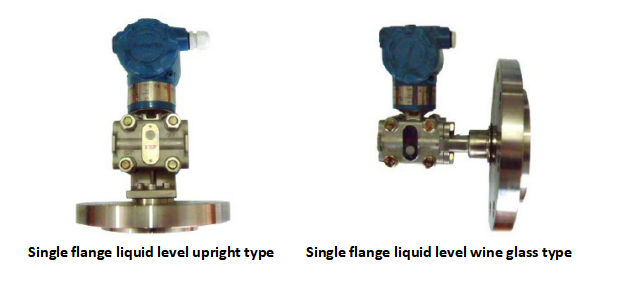

The YH1151/3351LT flange pressure/level transmitter adopts a differential capacitive pressure sensor, which can accurately measure the pressure of various containers. There are flat flanges and plug-in flanges. The flange has 3 inches or 4 Inches, the specifications have flanges of 1501b and 3001b, and flanges can also be customized according to users, and flange diaphragm materials are optional.

The key raw materials of YH1151/3351LT flange pressure/level transmitter. The components and parts are all imported or joint ventures. The whole machine has been rigorously assembled and tested. The product has advanced design principles, complete varieties and specifications, and installation and use. Convenience and other features. Because the appearance of this model completely integrates the structural advantages of the two most popular and widely used transmitters (Rosemount 3051 and Yokogawa EJA), it gives users a refreshing feeling, and it is in line with the traditional series. The product can be directly replaced in installation, and has strong versatility and substitution capabilities. In order to be suitable for the continuous improvement and development of the domestic automation level, this series of products not only has a small and exquisite design, but also has an intelligent function with HART fieldbus protocol.

The flange level transmitter is a dependable and accurate device commonly used in industrial settings to measure liquid levels in tanks and vessels. Built with exceptional engineering, it features a strong metal flange that securely attaches to the container wall for leak prevention. Its main function is to detect liquid levels precisely, utilizing advanced technology such as hydrostatic pressure sensors or capacitance probes. These sensors are strategically located within the flange unit to continually observe changes in pressure or conductivity caused by varying levels. Using this data, the transmitter converts it into an electrical signal which can be easily transmitted and interpreted by control systems for instantaneous monitoring and decision-making purposes. Thanks to their sturdy design, adaptability, and superior precision, flange level transmitters have become vital tools across multiple industries including oil refineries, chemical plants, and wastewater treatment facilities.

The flange level transmitter is a sophisticated tool that precisely measures and tracks fluid levels in various industrial settings by utilizing the principle of hydrostatic pressure. It features a flush diaphragm sealed between two flanges, allowing for accurate readings without direct exposure to the process fluid. Constructed from durable materials like stainless steel or ceramic, the diaphragm can withstand harsh environments and effectively measure aggressive or viscous fluids. The liquid level impacts the diaphragm, causing it to deflect. This deflection is then detected by a sensitive strain gauge attached to its backside. Through Wheatstone bridge circuitry, these strains are measured and converted into real-time data. This data is then transmitted through a 4-20mA current loop output or other standard industry protocols for remote monitoring and control purposes. With its reliable performance and adaptable nature, this instrument is essential for efficient operation in oil refineries, chemical plants, wastewater treatment facilities, and other industries where precise management of fluid is critical for smooth processes.

This product is widely used in petroleum, chemical, sewage treatment, urban water supply, machinery, metallurgy, electric power, scientific research and other enterprises and institutions to realize the measurement of liquid, gas or steam pressure, and is suitable for all-weather environments and various corrosion in various occasions Measurement and control of the pressure of sexual liquids, gases, and vapors.

▲High precision;

▲The range and zero point are continuously adjustable externally;

▲ Good stability and performance;

▲Positive migration can reach 500%, negative migration can reach 600%;

▲Two-wire system;

▲ Adjustable damping and overvoltage resistance;

▲ Solid sensor design;

▲ No mechanical moving parts, less maintenance;

▲ The whole series has a unified structure and strong interchangeability;

▲ Diaphragm materials that contact the medium are optional;

▲ Unilateral overpressure resistance;

▲ Low-pressure cast aluminum alloy shell

● Super measurement performance, used for pressure, differential pressure, liquid level, flow measurement;

● Digital accuracy: ±0.2%

● Simulation accuracy: +(-)0.75% +(-)0.1% F•S

● Full performance: +(-)0.25 F•S;

● Stability: 0.25% for 60 months;

● Turndown ratio: 100:1

● Measuring rate: 0.2S

● Miniaturized all-stainless steel flange, easy to install;

● The process connection is compatible with other products to achieve the best measurement;

● The only sensor in the world that adopts H alloy sheath, which achieves excellent cold and thermal stability.

● Standard 4-20mA with digital signal based on HART protocol, which can be controlled remotely.

Model | YH1151/3351LT flange type pressure transmitter (capacitive type) | |||||||

Code | Measuring range | |||||||

3 | 0-1.3~7.5KPa | |||||||

4 | 0-4-40KPa | |||||||

5 | 0-40~200KPa | |||||||

6 | 0-0.16KPa~1MPa | |||||||

Code | Output | |||||||

E | 4-20mA | |||||||

S | Smart HART protocol | |||||||

Code | Nominal diameter size mm | Insert barrel length mm | High-pressure side diaphragm material | |||||

A0 | 3〃80 | flat | 316LSST | |||||

A2 | 3〃80 | 50 | 316LSST | |||||

A4 | 3〃80 | 100 | 316LSST | |||||

A6 | 3〃80 | 150 | 316LSST | |||||

B0 | 4〃100 | flat | 316LSST | |||||

B2 | 4〃100 | 50 | 316LSST | |||||

B4 | 4〃100 | 100 | 316LSST | |||||

B6 | 4〃100 | 150 | 316LSST | |||||

C0 | 3〃80 | flat | Hastelloy C-276 | |||||

C2 | 3〃80 | 50 | Hastelloy C-276 | |||||

C4 | 3〃80 | 100 | Hastelloy C-276 | |||||

C6 | 3〃80 | 150 | Hastelloy C-276 | |||||

D0 | 4〃100 | flat | Hastelloy C-276 | |||||

D2 | 4〃100 | 50 | Hastelloy C-276 | |||||

D4 | 4〃100 | 100 | Hastelloy C-276 | |||||

D6 | 4〃100 | 150 | Hastelloy C-276 | |||||

E0 | 3〃80 | flat | Tantalum | |||||

F0 | 4〃100 | flat | Tantalum | |||||

Code | Mounting flange | |||||||

A | 3〃150lb | |||||||

B | 4〃150lb | |||||||

C | 3〃150lb | |||||||

D | 4〃150lb | |||||||

Code | Structural materials | |||||||

Flanges and joints | Exhaust/drain valve | Isolation diaphragm | Filling with liquid | |||||

22 | 316 stainless steel | 316 stainless steel | 316 stainless steel | Silicone oil | ||||

23 | 316 stainless steel | 316 stainless steel | Hastelloy C | |||||

24 | 316 stainless steel | 316 stainless steel | Monel | |||||

25 | 316 stainless steel | 316 stainless steel | Tantalum | |||||

33 | Hastelloy C | Hastelloy C | Hastelloy C | |||||

35 | Hastelloy C | Hastelloy C | Tantalum | |||||

Code | Options | |||||||

M1 | 0-100% linear indicator | |||||||

M3 | 3 1/2 digit LCD display meter | |||||||

M4 | Smart meter display | |||||||

B1 | Tube bending bracket | |||||||

B2 | Board-mounted bending bracket | |||||||

B3 | Tube mounted flat bracket | |||||||

D1 | The side relief valve is in the upper part of the pressure chamber | |||||||

D2 | The side relief valve is in the lower part of the pressure chamber | |||||||

No note | 1/2NPT taper pipe threaded joint | |||||||

C2 | T-shaped threaded joint M20×1.5, with rear welding! 14 Ball cone connector of impulse tube | |||||||

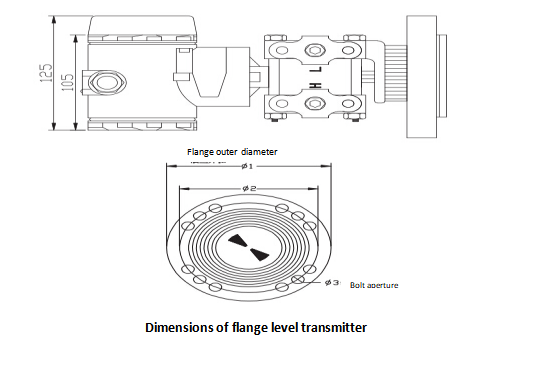

The mounting flange standard ANS1 has 3’’ and 4’’ specifications. The flange grades are divided into 150LB (2.5MPa) and 300LB (5.0MPa). The flange installation dimensions are shown in the following chart.

Dimensions of flange level transmitter

Mounting flange | Diaphragm component size | |||||||

Dimensions and specifications | Pressure Level | t | Φ1 | Mounting bolt | Φ4 | Φ5 | ||

Φ2 | Φ3 | quantity | ||||||

3〞 | 1501b | 30 | 190.5 | 152 | 19 | 4 | 127 | 66 |

4〞 | 1501b | 30 | 228.5 | 190 | 19 | 8 | 157 | 89 |

3〞 | 3001b | 35 | 209.5 | 168 | 22.2 | 8 | 127 | 66 |

4〞 | 3001b | 38 | 254.0 | 200 | 22.2 | 8 | 157 | 89 |

Note: It is the flange thickness; Ф1 flange outer diameter; Ф2 bolt distribution diameter; Ф3 bolt hole diameter; Ф4 diaphragm seal outer diameter; Ф5 insertion barrel outer diameter

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.