YF3051 series intelligent pressure/differential pressure transmitter, the central sensing unit adopts the world's leading high-precision silicon pressure, differential pressure sensor technology and packaging process, the single crystal silicon pressure, differential pressure sensor is located at the top of the metal body, away from the contact surface of the medium , To achieve mechanical isolation and thermal isolation; the glass sintered sensor lead achieves high-strength electrical insulation with the metal substrate, which improves the flexibility of electronic circuits and the ability to withstand transient voltage protection. The platinum level accuracy reaches ±0.05%, and the one-way overpressure can reach up to 25MPa. Excellent static pressure performance, the optimal static pressure error can be controlled within ±0.05%/10MPa, the temperature effect is minimal, and the optimal static pressure can be controlled within ±0.04%/10K.

The circuit design adopts a modular design with a microprocessor as the core and assisted by advanced digital isolation technology, so that the instrument has extremely high anti-interference and stability. The Hart protocol is used for communication, which can be remotely operated through a Hart handheld communicator or a computer installed with Hart software to complete the measurement information configuration. At the same time, digital compensation technology is used, and the transmitter is compensated through the built-in temperature sensor to improve the measurement. Accuracy, reduced temperature drift, good long-term stability and high reliability.

The infrared wireless setting and one-key reset function are designed to meet the requirements of safe operation in dangerous occasions. It is very convenient for quick menu operation, and can complete all parameter settings, and comprehensively improve the performance of the transmitter.

⊙Advanced monocrystalline silicon pressure sensor technology and packaging process, carefully developed an ultra-high performance pressure and differential pressure transmitter with international leading technology

⊙The microprocessor is the core and the modular design assisted by advanced digital isolation technology makes the instrument have extremely high anti-interference and stability

⊙Powerful 24-bit ADC achieves high accuracy

⊙Innovative dual compensation technology, true 0.075 high precision

| Range limit | Within the upper and lower limits of the measuring range, it can be adjusted arbitrarily It is recommended to select a range code with the lowest possible turndown ratio to optimize performance |

| Zero point setting | Zero point and range can be adjusted to any value within the measurement range in the table, as long as: calibration range ≥ minimum range |

| Influence of installation location | The change of the installation position perpendicular to the diaphragm surface will not cause the zero drift effect. If the installation position and the diaphragm surface change more than 90°,It will cause zero influence in the range of <0.4kPa, which can be adjusted by zero adjustment, no range influence |

| Output | Two-wire system 4-20mA, in line with NAMIR NE43 standard, superimposed digital signal (Hart protocol) Choice of linear or square root output |

| Output signal limit | Imin=3.9mA,Imax=21.0mA |

| Fault warning | If the sensor or circuit fails, the automatic diagnosis function will automatically output 3.9 or 21.0mA (user can pre-set) |

| Alarm current | Low report mode (minimum): 3.9mA |

| High report mode (maximum) | 21 mA |

| Alarm current default setting | High report mode |

| Response time | The damping constant of the amplifier component is 0.1s; the time constant of the sensor is 0.1 to 1.6s, depending on the range and the range ratio. The additional adjustable time constant is: 0~100s |

| Preheat time | <15s |

Measuring medium: gas, steam, liquid

Inaccuracy: ±0.05%, ±0.075%, ±0.1% (including linearity, hysteresis and repeatability from zero)

Stability: ±0.1%/3 years

Ambient temperature influence: ≤±0.04%URL/10℃

Influence of static pressure: ±0.05%/10MPa

Power supply: 10~36V DC (24V DC recommended)

Power influence: ±0.001% /10V (10~36V DC), negligible

Reference accuracy of range adjustment: if TD>10 (TD=maximum range/adjustment range) then: ±(0.075×TD)% the square root output accuracy is 1.5 times the above linear reference accuracy

Ambient temperature: -40℃ ~85℃

Measuring medium temperature: -40℃~120℃

Storage temperature: -40℃ ~105℃

Display: LCD, OLED

Display module temperature: -20℃~70℃ (LCD), -40℃~80℃ (OLED)

| Range | Unilateral overload (negative end) | Unilateral overload (positive end) | Bilateral static pressure | |

| A | 1KPa | 1MPa | 1MPa | 16MPa |

| B | 6KPa | 2MPa | 2MPa | 16MPa |

| C | 40KPa | 3MPa | 3MPa | 25MPa |

| D | 400KPa | 10MPa | 10MPa | 25MPa |

| E | 4MPa | 10MPa | 10MPa | 25MPa |

A. Radio frequency radiation test

| Test field strength | Frequency Range | EUT placement | Polarization direction | Test results | ||

| Product No. | ||||||

| 24283 | 24281 | 24282 | ||||

| 3V/m | 80MHz-1GHz | Upright | Horizontal polarization Vertical polarization | Inside the test sample Keep the data unchanged Inside the test sample Keep the data unchanged | Inside the test sample Keep the data unchanged Inside the test sample Keep the data unchanged | Inside the test sample Keep the data unchanged Inside the test sample Keep the data unchanged |

B. Power frequency magnetic field immunity test

| Magnetic field strength | Test Result | ||

| Product No. | |||

| 24283 | 24281 | 24282 | |

| 400A/m(X、Y、Z) | The memory data of the tested sample remains unchanged | The memory data of the tested sample remains unchanged | The memory data of the tested sample remains unchanged |

Measuring capsule: stainless steel 316L

Diaphragm: stainless steel 316L, Hastelloy C

Process flange: stainless steel 304, 316L

Nuts and bolts: carbon steel galvanized, stainless steel

Filling fluid: silicone oil, fluorine oil, high temperature silicone oil, etc.

Sealing ring: nitrile rubber, fluorine rubber, polytetrafluoroethylene

Transmitter housing: aluminum alloy material, sprayed with epoxy resin on the outside

Shell seal: Nitrile rubber

Nameplate: stainless steel 304

Weight: 2.6kg (no: mounting bracket, process connection)

Shell protection level: IP67

Explosion-proof grade: Exd Ⅱ CT6, Exia Ⅱ CT6

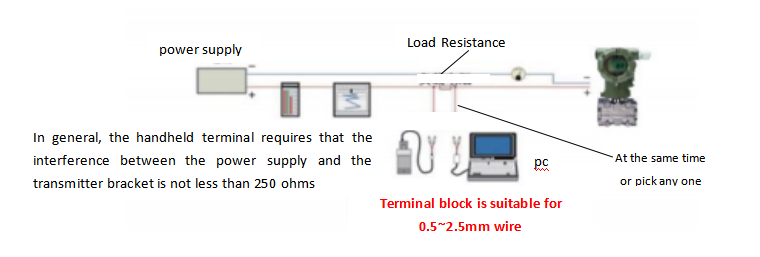

Power supply and load conditions

The power supply voltage is 24V, R ≤ (Us-10V)/Imax Ω

Where Imax=21 mA

Maximum power supply voltage: 36VDC

Minimum power supply voltage: 10VDC

Digital communication load range: 250 ~ 600Ω

Process connection

Both ends of the process connection flange have NPT1/4 and M10 or UNF7/16 internal threads

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.