Product Overview

kaidi KFLS10-EH room temperature type tuning fork level switch is a kind of solid material level switch specialised in measuring powder and fine particles, it can measure fine sand, fine chemicals, flour, salt and other materials, the lowest density is up to 0.008g/cm³, which is especially suitable for ultra-low density material level measurement, it has a wide range of adaptability and very high reliability.

Working Principle

The probe of the tuning fork level switch is based on the tuning fork design, and adopts piezoelectric devices to realise the vibration drive and detection of the fork body. When not in contact with the material, the tuning fork vibrates freely at the resonant frequency. When the tuning fork is in contact with the measured material, the vibration amplitude of the tuning fork decreases significantly, and the amplitude of the output signal of the piezoelectric detecting device decreases accordingly, and the signal change is detected and analysed by the intelligent circuit and outputs a switching signal. The product through a reasonable increase in the area of the fork body, and the fork body after precision tuning, the sensitivity can be greatly improved, can measure the density of materials as low as 0.008g/cm³.

Product Features

(1) Reasonable fork area design, and the fork is precision tuned, can measure density as low as 0.008g/cm³.

(2) Dedicated to powder and fine particles of material measurement, can effectively prevent hanging material.

(3) Rich self-diagnostic function, can accurately locate fault information.

(4) Simple installation, maintenance-free.

(5) Through the CE and gas explosion-proof and gas intrinsically safe explosion-proof certification.

(6) Adopt corrosion-resistant material 316L.

Technical parameters

Applicable materials | Media Type | Powder, fine granular materials |

Density of the medium | ≥0.008 g/cm3 | |

particle size | Maximum 10mm | |

Probe parameters | vibration frequency | Approaching 140Hz |

Tuning fork length | 100mm | |

response time | contact material | 0.5s |

No material | 1s | |

power supply | Relay output type | 19…60VDC 19…250VAC 50/60Hz |

2-wire type | 10~36V DC | |

Maximum power consumption | DC<3W, AC <15W | |

signal output | relay (electronics) | AC250V/4A, DC60V/4A |

two-wire system | NPN, 400MA PNP,400MA | |

working environment | process pressure | -1~40bar |

process temperature | Normal temperature -50~150℃ | |

High temperature -50~250℃ | ||

Ultra-high temperature -50~400℃ | ||

environmental temperature | -40~80℃ | |

Storage and transport temperature | -40~80℃ | |

Cooling Specifications and Parameters (Ultra High Temperature Models Only) | Cooling inlet pipe | 6×4 size (O.D. 6mm) PU air hose |

cooling air pressure | 0.8Mpa | |

Minimum flow rate of cooling gas | debugging required | |

overpressure protection | Relay output type | Category III, level I |

2-wire type | Category III, level II | |

safety certification | protection class | IP65/IP66 |

Explosion-proof grade | Explosion-proof: Ex d IIC T6~T1 Gb | |

Intrinsically safe: Ex ia IIC T6~T1 Ga | ||

CE | LVD Certificate and EMC Certificate | |

material (that sth is made of) | housings | Aluminium alloy, stainless steel |

ground terminal | 316L | |

process connection | 316L, 316L coated PTFE | |

prong of a fork | 316L, 316L coated PTFE | |

Process sealing | Rubber.PE gasket |

Product Applications

(1) Level measurement of pyrogenic silica.

The density of pyrogenic silica is as low as 0.01g/cm³, and this product can measure as low as 0.008g/cm³, which fully meets the measurement requirements of this working condition.

(2) EPP, EPS production process of pre-feeding machine, moulding machine material level measurement.

(3) Material level measurement of zircon sand and petroleum coke.

(4) Other process temperature does not exceed 150 ℃ (ultra-low density) particles, powder and other material level measurement.

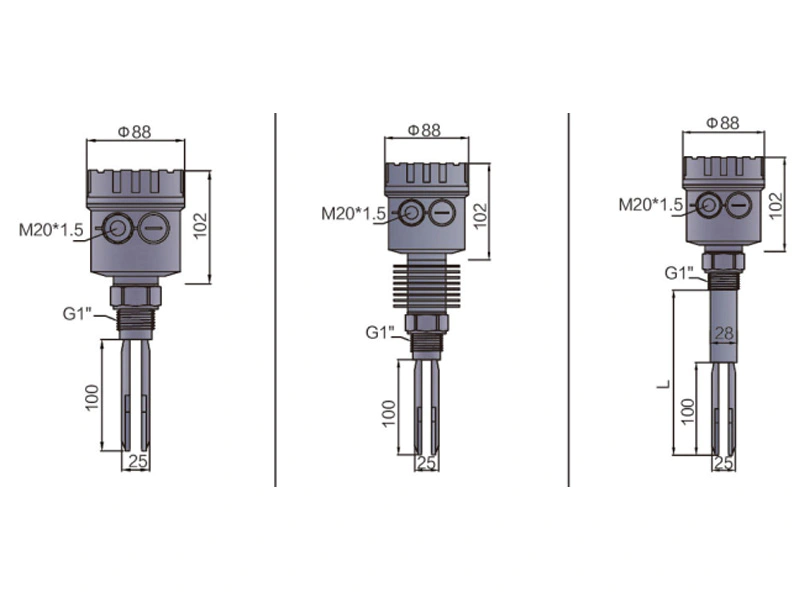

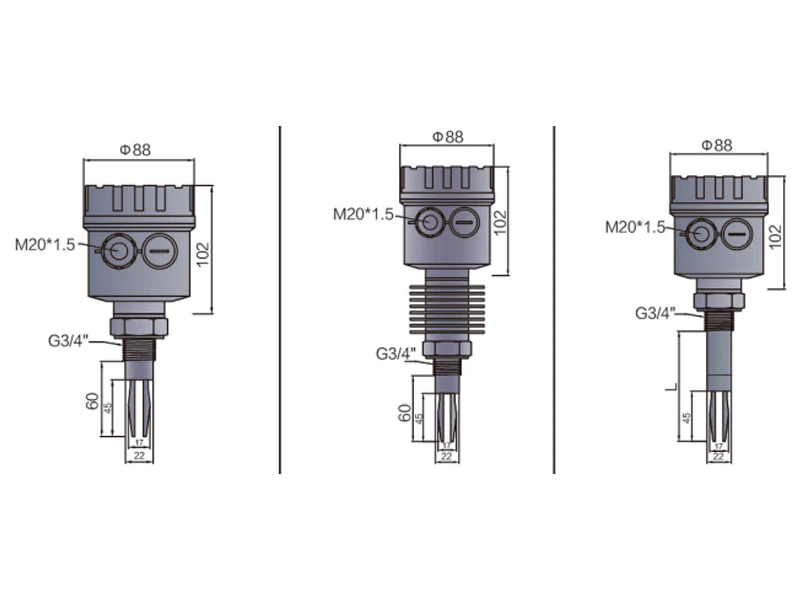

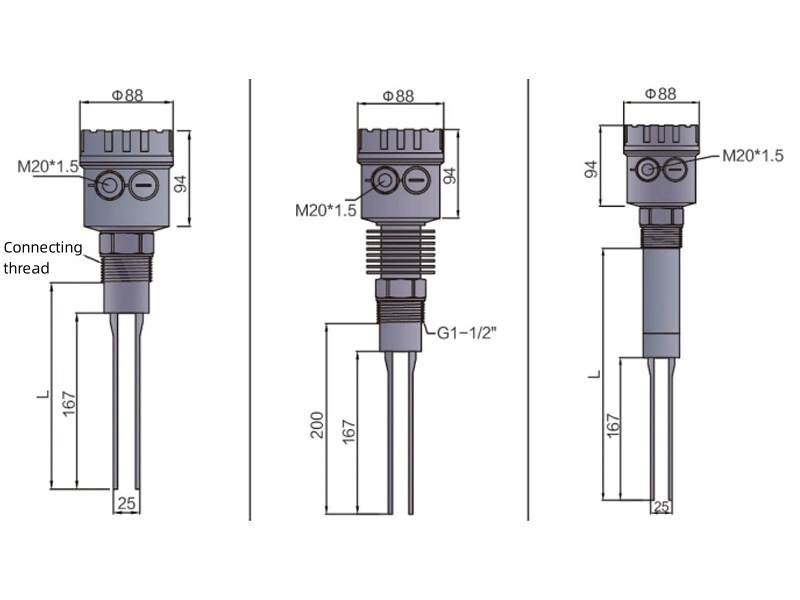

Product Size

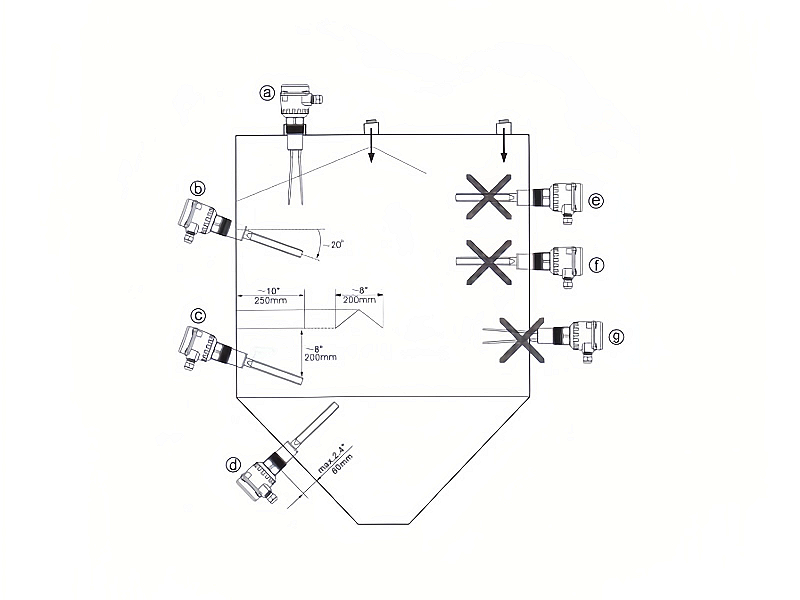

Product Installation

Installation Precautions:

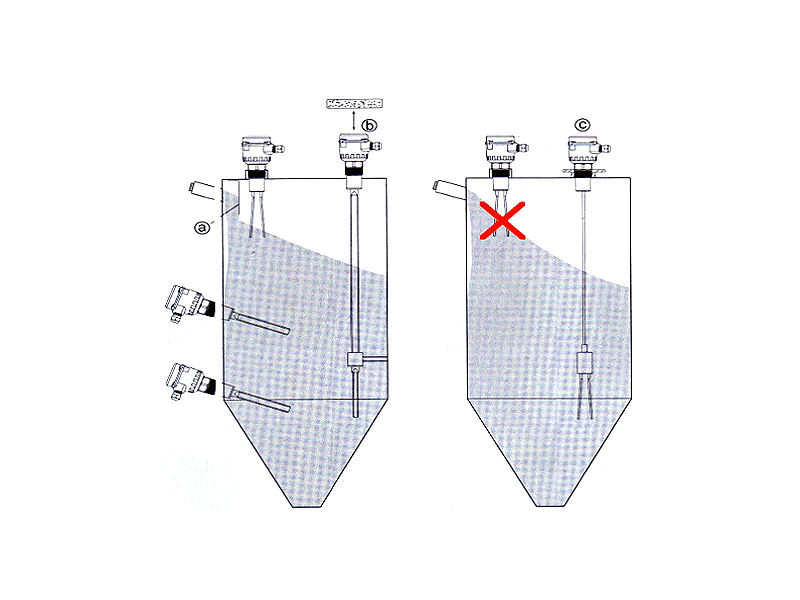

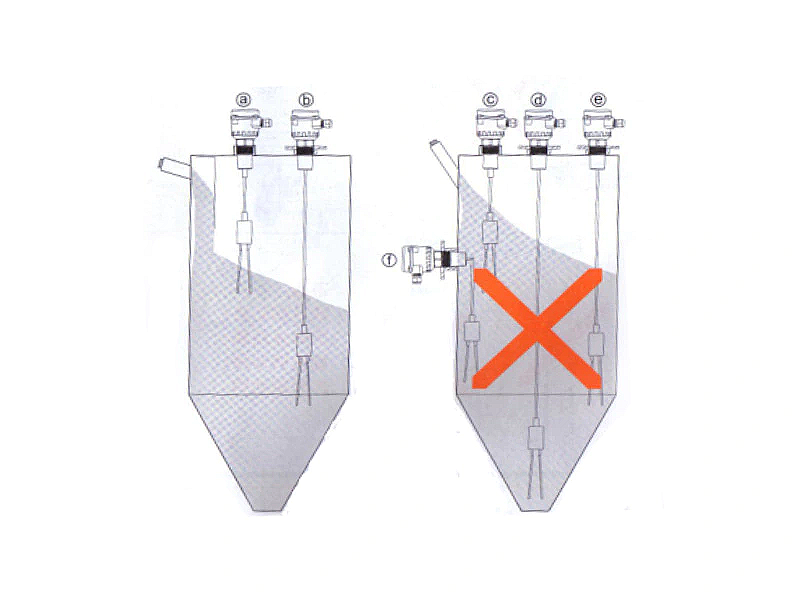

1. When installed horizontally, the material level switch should be tilted 20° to prevent the phenomenon of hanging material. In order to reduce the direct impact of the material on the probe, you can install a protective baffle above the vibrating body, and the length of the baffle should be greater than the length of the horizontal installation of the probe. For general materials, the cross-section shape of the protective baffle is inverted V-shaped; for rough and dense materials, the cross-section shape of the protective baffle adopts positive V-shaped, in order to reduce the wear and tear of the material on the protective baffle. As shown in Figure I.

2. The material level switch should be avoided to be installed in the inlet to prevent damage or false operation caused by the impact of materials, and the fork face and the direction of media flow should be consistent.

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.