The vibrating fork level switch for solids is designed using the principle of the damping effect of the medium on the vibrating fork vibration and the piezoelectric effect. The

sensing part for detecting the material (liquid) level is composed of the vibrating fork for liquids, which has a fixed vibration frequency and amplitude vibration. When the vibrating fork for pharmaceuticals is subjected to medium damping, the vibrating fork for solids stops vibrating, and the control circuit drives the relay to send out a switch signal.

The product can adapt to the harsh working conditions and work reliably. It is the most widely used product in the material (liquid) level switch instrument.

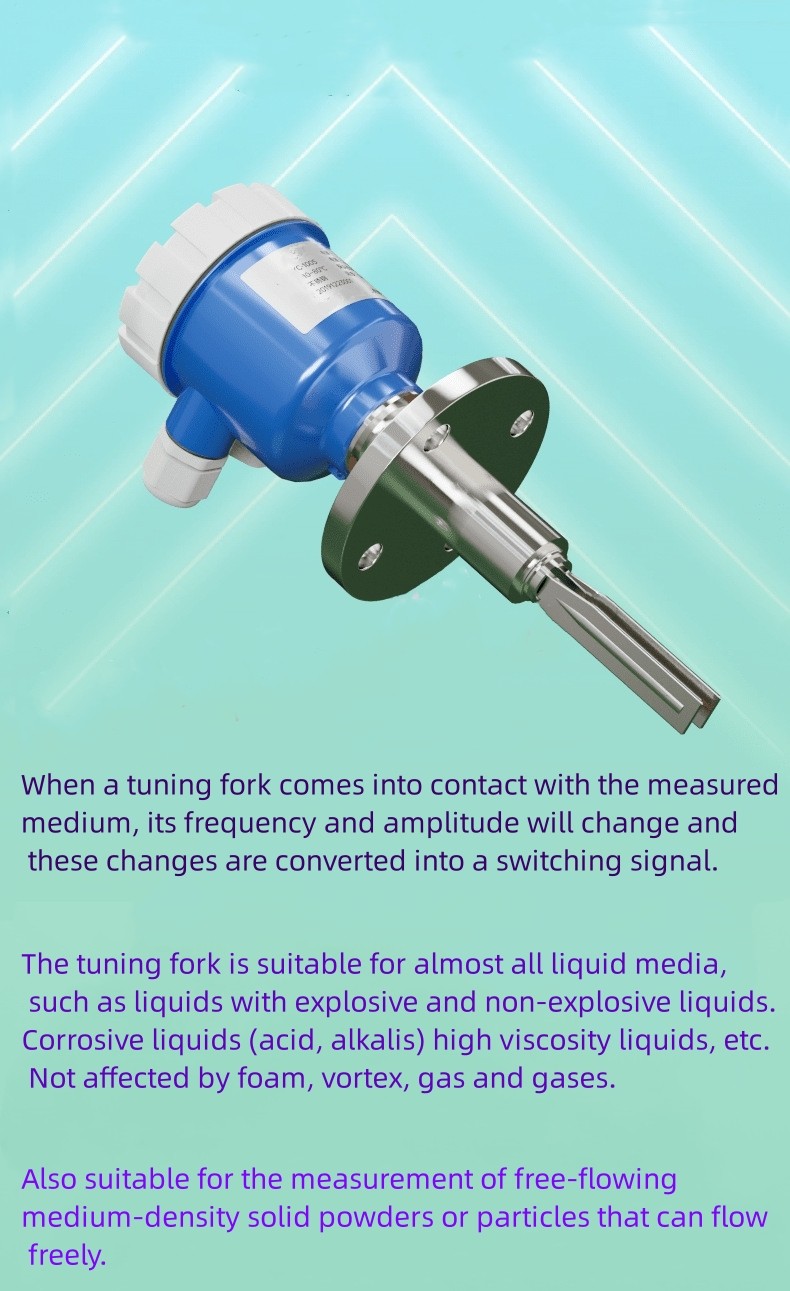

Vibration type level switches are composed of a vibrating rod made from stainless steel. As it contacts the material in a tank, its oscillation stops, prompting the switch to output a detection signal. These models also feature two forks that vibrate at their mechanical resonance frequency, allowing them to self-clean when they come into contact with air. When the forks are exposed to liquid, the frequency drops and this is detected by the switch electronics. This prompts it to actuate an alarm, pump or valve.

Vibrating fork level switch working principle:

It works like any alarm switch that turns on/off when the level of fluid goes above or below a predetermined level. In the event of a variation in the level, the device raises an alarm or produces a sound. A level switch's output can be voltage dependent or not, depending on the device. It may sometimes have a voltage-free contact, or sometimes it may have a fixed voltage of 0-12.

Vibrating fork level sensors operate by vibrating tuning fork level sensor continuously at their natural frequency and detecting the change in frequency and amplitude when application media is present. It is important to consider the type of application media when monitoring given parameters.

1.Amplitude of vibration: Vibrating Level Switch for Solids

As the material level increases and comes into contact with the Vibrating Fork tines, the amplitude of oscillation of tuning fork level switches dampens. When the amplitude drops below a set threshold, the onboard electronics changes the outputs (relays).

2.Vibrating Fork Level Sensor for Solids

As the tuning fork type level switch is covered with liquid application media, its natural frequency decreases. The threshold frequency is set to match the natural frequency of tuning fork type level switches under water.

What is the use of tuning fork level switch

A tuning vibrating fork level switch for solids is a sensor that generates an electrical contact at a certain level. The models are easy to use and are ideal for controlling powders and fine-grained vibrating fork for solids. They are also suitable for mining, chemical processing, and food and beverage applications.

Vibrating fork level switches offer several advantages for solids level measurement:

High accuracy: Vibrating fork level switch provide precise measurements, ensuring that the material levels are accurate.

Reliability: Vibrating fork level switches are highly reliable and require minimal maintenance due to their robust design.

Compatibility: They can be used with a wide range of solid materials, including powders, granular materials, and fine particles.

Continuous measurement: Vibrating fork level switches can provide continuous measurement, allowing for real-time monitoring of material levels.

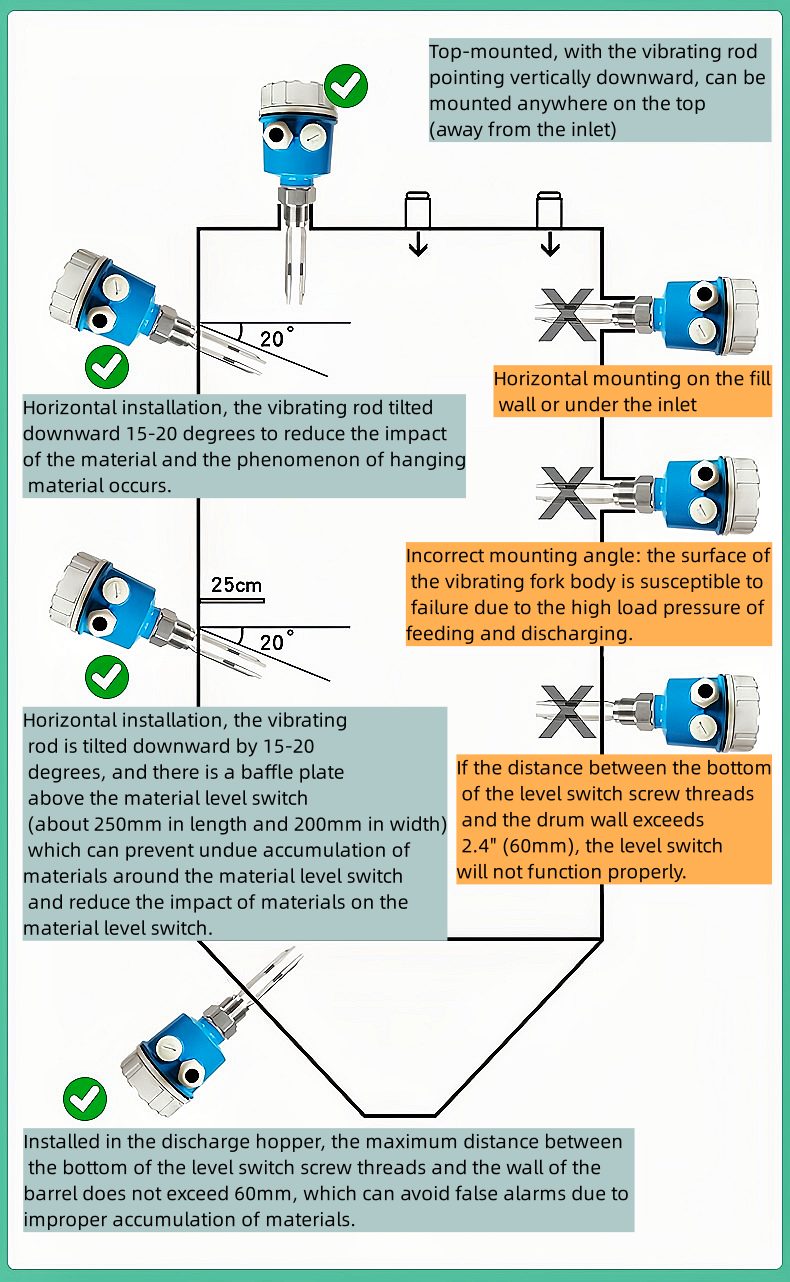

Easy installation: The installation process is quick and straightforward, as they can be fitted directly into the vessel or silo without the need for any additional equipment.

Cost-effective: Vibrating fork level switches are cost-effective and offer an affordable option for solid level measurement compared to other technologies.

Overall, vibrating fork level switches offer a reliable, accurate, and cost-effective solution for solids level measurement in a wide range of industries, including food and beverage, pharmaceuticals, plastics, and mining.

①With automatic learning function, through the button, without calibration, you can learn different medium densities;

②All metal structure, sturdy and durable;

③The fork body has a large vibration amplitude, which can reach more than 10mm, which can shake off the low-viscosity local hanging material on the induction rod to prevent misoperation;

④The super bright red LED light provides a more convenient and instant warning function for the material level monitoring of the on-site personnel;

⑤Wide AC and DC power input can not only effectively reduce inventory, but also have a wider range of applications;

⑥It is suitable for level monitoring of liquid, granular and thick substances.

vibrating fork is suitable for chemical plastics, pharmaceuticals, feed, environmental protection, water treatment, cement and chemical fertilizers, food powder and other manufacturing and processing industries.

The piezoelectric crystal element is used to generate vibration waves. When the measured medium contacts the fork body, the amplitude and amplitude of the vibrating fork are changed. The intelligent control circuit detects this change and converts it into the corresponding output switch signal, such as: Relay, NPN , PNP.

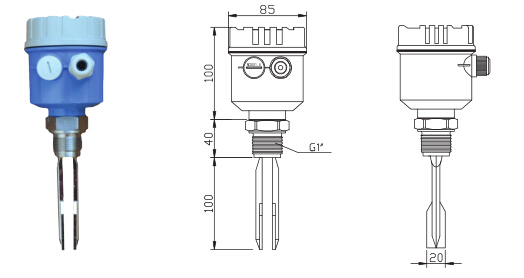

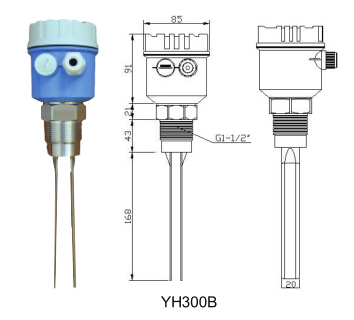

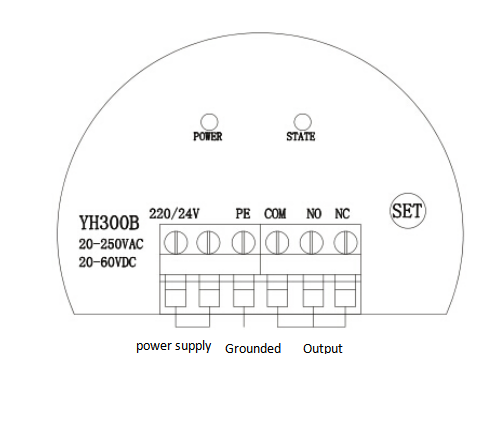

✧Connection port specification: G1-1/2〃

✧ Wire inlet specification: M20×P1.5

✧ Measuring medium: liquid/powder/solid

✧Application scope: through the learning function, any powder, granule and liquid can be used

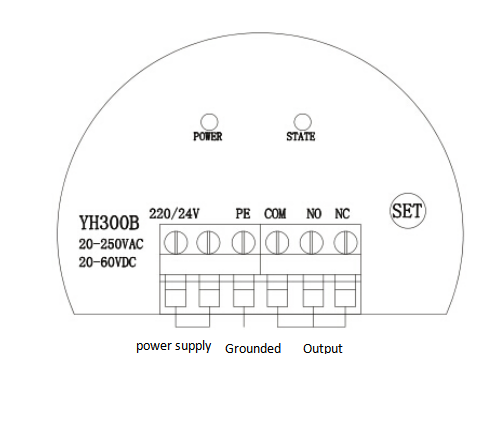

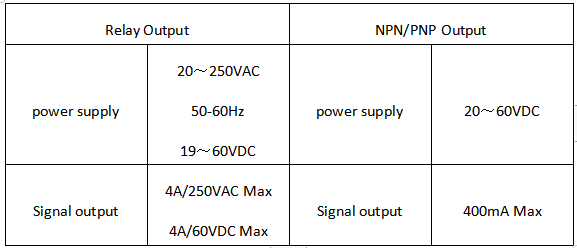

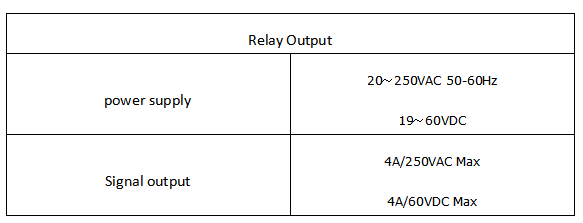

✧ Power supply voltage: 20~60VDC 20~250VAC 50/60Hz

✧ Switching time: 3s

✧ Ambient temperature: -40~70℃

✧ Storage temperature: -40~85℃

✧ Medium temperature: -40~150℃

✧Operating pressure: -1~40bar

✧Connection method: G1-1/2〃, insert, flange

✧Shell material: aluminum alloy

✧Fork body material: stainless steel 304/stainless steel 316 relay output, load AC250V/4A, DC60V/4A

✧Output mode: open collector (NPN) output, load 400mA open collector (PNP) output,

Load 400mA

✧Power consumption: 3W Max when DC power supply. 5W Max when AC power supply.

✧Standard shaft specification length: 240 300MAX, 400V 700MAX, 2000V 125.5

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.