①Strong adaptability: the different electrical parameters and density of the measured liquid level have no influence on the measurement. Harsh conditions such as structure, agitation, turbulence, bubbles, vibration, medium viscosity, high temperature, and high pressure have no effect on the detection.

② Maintenance-free: Since the detection process of the vibrating fork limit switch is completed by an electronic circuit, there are no moving parts, so there is no need for maintenance once it is installed and put into operation.

③ No adjustment required: Because the detection of the vibrating fork limit switch is not affected by the electrical parameters and density of the measured medium, no on-site adjustment is required no matter what liquid level/material level is measured.

◆Tap water, mineral water, pulp, glue, dyes

◆Mud, alkali solution, acid solution

◆Beer, beverage, gas-producing liquid

◆Solid powder with good fluidity

◆ Medium temperature range: -20℃~80℃

◆ Ambient temperature: -20℃~60℃

◆ Environmental humidity: ≤95%RH

◆ Measured medium: liquid, powder or granular solid

◆ Density of the measured medium: solid ≥0.1g/cm3; liquid ≥0.7g/cm3;

◆ The measured solid particle size: ≤10mm

◆ Maximum liquid viscosity: <1000mm2/S

◆ The angle of repose of the measured medium: ≥200

◆ Pressure range: ≤1MPa

◆ Material of shell and fork body: 1Cr18Ni9Ti

◆ Shell protection grade: IP65

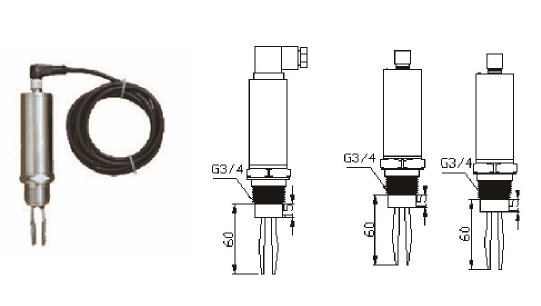

◆ Connection method: G1 3/4 thread; flange (selected by the user)

● Very high viscosity liquids and larger granular materials are not suitable for changing the switch.

● When installing and constructing, make sure that the fork body is not subject to strong impact, which may damage the piezoelectric crystal.

● When measuring dust and liquids with higher viscosity, the two parallel fork plates of the fork body should be perpendicular to the ground (the direction mark of the fork body should be dashed at this time).

Up or down) to ensure that the material can easily flow out from between the fork plates.

● The power line and signal line of the sensor should not be laid in parallel with the power line of other high-power equipment, twisted together, and run through the same conduit.

● When the output drives an inductive load (such as AC contactor, etc.), a "surge suppressor" should be connected in parallel at both ends of the load.

● When there are high-power equipment and variable frequency equipment on site, DC24V power supply should be used as much as possible.

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.