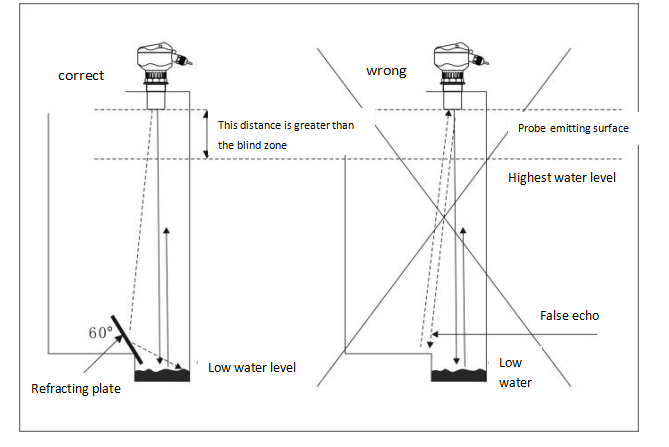

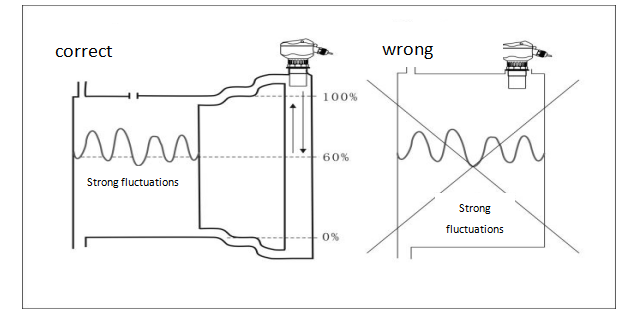

In recent years, radar level gauges have been progressively replacing ultrasonic level gauges as the more prevalent non-contact level measurement technology in field measurement applications across industries such as chemical, petrochemical, power generation, food and beverage, wastewater treatment, and powder storage and transportation. This trend is driven not by a single factor but by a combination of factors, including: differences in physical principles, environmental adaptability, measurement accuracy and stability, process compatibility, digitalization and intelligent diagnostic capabilities, and improvements in total cost of ownership.While ultrasonic level transmitters retain competitiveness in low-cost and simple operating conditions, radar level transmitters are poised to become the mainstream technology in future developments. This study reviews the differences and application boundaries between the two technologies, synthesizing key considerations for selecting appropriate measurement techniques based on academic research and engineering practice. Radar Level Transmitters and Ultrasonic Level TransmittersI. Physical Characteristics Differences Between Electromagnetic Waves and Sound WavesUltrasonic level transmitters measure distance by timing the propagation of sound waves, making them highly susceptible to temperature, humidity, gas composition, and turbulence. For instance, in high-temperature steam environments, fluctuations in the speed of sound through air can cause measurement errors. Simultaneously, foam and mist can absorb or scatter ultrasonic signals, generating false echoes.In contrast, radar level transmitters emit microwave or millimeter-wave electromagnetic signals. Electromagnetic waves are virtually unaffected by temperature and humidity in gaseous phases, enabling effective penetration through steam, mist, and dust. Both manufacturer reports and academic studies indicate that radar echo stability significantly outperforms ultrasonic performance in steam clouds, dust-filled enclosed compartments, and agitated vessels. Radar level gauges demonstrate significant advantages in anti-interference performance.II. High-frequency and FMCW technologies enhance measurement resolution.Traditional pulse radar has limited resolution, but with the development of 24 GHz and 80 GHz high-frequency bands and FMCW (Frequency Modulated Continuous Wave) technology, the resolution and interference resistance of radar level gauges have significantly improved.High-frequency radar features a narrower beam angle, reducing wall echo interference;80 GHz technology enables smaller antenna sizes, making it more suitable for compact vessels;FMCW delivers higher signal-to-noise ratio and dynamic range, enabling detection of weak echoes—particularly advantageous for liquids with low dielectric constants.These advancements enable radar to perform exceptionally well in containers with complex geometries, narrow tanks, and agitated conditions. Level measurement in mixing tanks is more stable and reliable.III. Reduced Blind Spots and Installation FlexibilityUltrasonic probes typically have a ±10mm “blind zone,” making accurate measurement difficult when liquid levels are too close to the container top. In contrast, high-frequency radar can often reduce the blind zone to just a few centimeters, significantly enhancing feasibility for small tanks or shallow tanks.This eliminates the need for engineers to install bypass pipes or extension tubes to reduce the blind zone, simplifying installation complexity and reducing maintenance points. For industries requiring frequent cleaning, such as food and pharmaceuticals, this simplified installation is particularly crucial.IV. Measurement Reliability Under Foam and TurbulenceIn fermentation, dairy, papermaking, and chemical reaction processes, liquid surfaces are often covered by foam or bubbles. Ultrasonic waves scatter energy within foam, frequently causing signals to be completely attenuated and interrupting measurements.Radar, however, relies on dielectric constant differences. Even when a foam layer exists on the liquid surface, it can identify the true liquid surface echo in most cases. Through signal processing algorithms, radar distinguishes between foam reflections and liquid surface reflections, enhancing data reliability. Easily identify foam levels, with measurements as reliable as ever.V. Long-Range and High-Precision PerformanceFor large tanks or silos exceeding 20 meters in height, ultrasonic signal attenuation and sound velocity fluctuations significantly reduce measurement accuracy. Radar, with its superior signal penetration and interference resistance, maintains stable measurements across ranges of 30–120 meters or even longer.Additionally, radar typically achieves accuracy within ±1–2 mm, whereas ultrasonic systems generally maintain only ±5–10 mm precision. In chemical reactors, batching processes, or industries requiring strict inventory management, this accuracy gap can directly impact production quality and economic efficiency.VI. Intelligent Systems and Remote DiagnosticsModern radar level transmitters widely support industrial protocols such as HART, Modbus, and Profibus, while progressively integrating Bluetooth and wireless communication. This enables engineers to perform parameter configuration, waveform diagnostics, and firmware upgrades from safe zones or remote workstations.In contrast, while ultrasonic level transmitters also offer digital versions, they lag behind in waveform processing, diagnostic algorithms, and remote upgrade capabilities. Academic research indicates radar level transmitters hold greater advantages in intelligent diagnostics and Industry 4.0 integration.VII. Cost and Lifecycle ConsiderationsHistorically, radar level transmitters were limited by their higher cost. However, with the mass production of integrated 80 GHz chips and antennas, prices have significantly decreased. Many plants conducting lifecycle cost assessments have found that while radar level gauges have a higher unit price than ultrasonic gauges, they offer superior overall economics by reducing false alarms, downtime, and maintenance costs.Consequently, in applications demanding high safety and reliability (such as petrochemical tank farms and hazardous chemical storage tanks), an increasing number of enterprises are opting for radar level gauges.VIII. Application Boundaries and Selection RecommendationsNot all scenarios require radar. In budget-sensitive, open-environment applications where measurement accuracy is not critical—such as open channels in water treatment plants or small reservoirs—ultrasonic technology remains a cost-effective solution.Scenarios where radar is preferred: High-temperature environments, condensing steam, foaming conditions, dusty atmospheres; large tanks, deep silos, remote operations; process control points requiring high precision and continuous monitoring.Scenarios where ultrasonic is preferred: Low-cost water tanks/channels, simple operating conditions, low-risk storage tanks.Hybrid strategy: Deploy radar at critical points and ultrasonic at secondary points to optimize overall investment and operational efficiency.ConclusionRadar level gauges are gradually replacing ultrasonic level gauges, driven by the convergence of mature technology, enhanced adaptability to operating conditions, and the trend toward industrial intelligence. With the widespread adoption and decreasing cost of 80 GHz high-frequency FMCW technology, this replacement trend will accelerate. Ultrasonic technology will retain its market share in certain low-cost, low-risk applications, but radar level gauges are undoubtedly the future mainstream.

Read More>>