BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI level gauge manufacturer.

Products

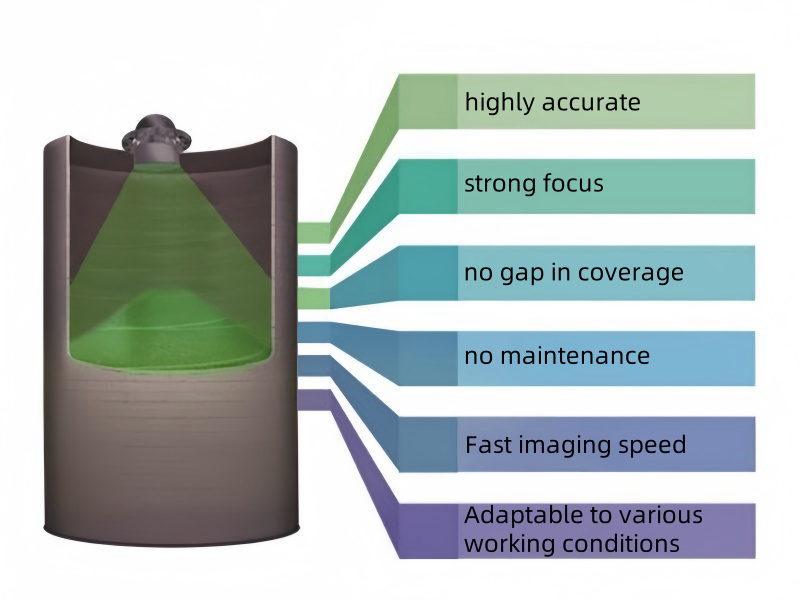

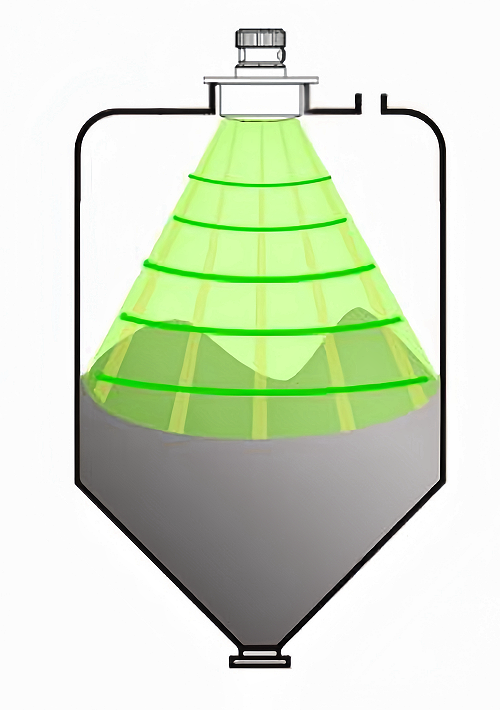

The KD-3D-05 radar is based on MIMO phased array technology and uses mathematical modeling for 3D holographic imaging.holographic imaging to provide accurate bulk solids and powders shapeVolume and level measurements in real time for bulk solids and powders. No matter what type of material, product characteristics, storage bin type, size or storage environmentsize or the harshness of the storage environment. The unit consists of an integrated array of five antenna modules that produce a unique, high-quality antenna signal.array of five antenna modules that generate unique low frequency acoustic waves that penetrate the dust and pick up the material-generatedecho generated by the material. Using these antennas, the device not only measures the time/distance of each echo, but also their direction.direction of each echo. By collecting multiple echoes at different distances and in different directions, the KD-3D-05 can accurately measure the time/distance of each echo in real time.KD-3D-05 can accurately calculate the volume of material stored in the silo in real time. At the same time, theKD-3D-05 software also generates a three-dimensional view of the material in the silo. Sound waves combined with a self-cleaningThe sound waves, combined with the self-cleaning feature, prevent material from adhering to the internal working position of the antenna array, ensuring a cleaner environment, no matter how dusty the environment.This ensures long term reliability and low maintenance, no matter how harsh and dusty the environment.The

Industry Challenges

1. Volumetric measurement of grain, flour and solid additives

Corporate grain inventory management and the various processes of the brewing and fermentation process need to ensure that efficient material supply and delivery is achieved throughout the production

process, they need to ensure efficient material supply and delivery throughout the entire production process. To do this, they require real-time visibility of the volume of material and related values in each

The main challenge was to be able to view in real time the volume of the material in each silo and the associated values:

▲ Because it is a solid, the surface of the material is not flat and changes constantly as the silos are filled or emptied, resulting in a single point of contact.

Because it is a solid, the surface of the material is not flat and changes as the silo fills or empties, rendering single-point cone projection measurements ineffective.

▲ Due to the environment inside the silo, it is often difficult to read measurements due to the dusty conditions.

▲ Certain materials tend to build up and stick to the walls of the silo, which means that although they take up

This means that although they occupy space, they cannot actually be used for production.

All of these factors make it more difficult to measure the amount of material available in a silo and the amount of space left available.

Inadequate knowledge of material availability can mean unintended production losses due to lack of material, and unintended production losses due to insufficient capacity.

Inadequate knowledge of material availability can mean unexpected production losses due to lack of material, the risk of overfilling silos due to insufficient capacity, and inefficiencies in planning material deliveries.

Inefficiencies in planning material availability.

2. Level and volume measurement of cement silos

Companies need to measure the level and volume of their cement silos. A typical cement silo is 30 meters high and has a lot of dust inside.

There is a lot of dust inside. The user had previously installed guided wave radar and ultrasonic level transmitters from another supplier.

level transmitters from another supplier, but neither system provided effective measurements and the customer found it necessary to regularly climb into the silo to see what was going on inside.

The customer also found that it was necessary to regularly climb into the silo to see what was going on inside. This was time-consuming and a safety hazard. The main challenge:

▲ Interference with level meter measurement stability and accuracy due to dusty conditions.

▲ The level meter was still able to accurately track the surface of the silo during filling and emptying.

▲ Users are not able to observe a clear view of the material in the silo in real time and measure the results in real time for

Observation.

▲ Operators need to climb to the top of the cement silo to check the material condition

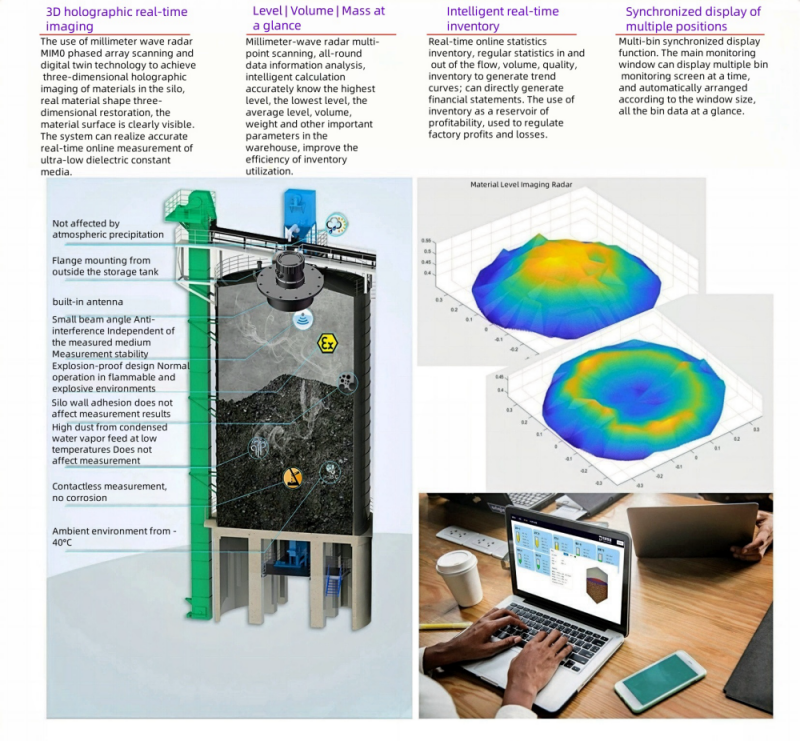

In response to the demand for accurate measurement of material volume and level inside the silos of food, power, cement, etc., we provide customers with reliable and stable measurements by means of 3D imaging level meters and their visualization functions. The company has installed KD-3D-05 in cement silo, power plant, food and other silos, because of dust, moisture, electromagnetic interference and other conditions will not give the level meter measurement function.problems, while sampling 3D real-time scanning imaging technology, so the level meter can still accurately track the surface during silo filling and emptying.and emptying period can still accurately track the surface condition, and will not be due to the utilization of multi-point fixed coneThe measurement accuracy is not subject to deviations and technical volume inaccuracies due to the use of multi-point fixed cones. InstallationAfter installation, the user receives a clear view of the material in the silo and realizes a significant improvement in measurement reliability.and the reliability of the measurement is significantly improved. More importantly, the operator no longer has to climb to the top of the silo to check the material after installing the level meter.and more importantly, with the installation of the level meter, the operator no longer has to climb to the top of the silo to check the material.

technological innovation

3D holographic real-time imaging

Completely independent use of millimeter-wave radar MIMO phased array scanning and digital twin technology to achieve 3D holographic imaging of the materials in the silo, the system can achieve accurate and reliable real-time online measurement of ultra-low dielectric constant media.

real-time inventory

Real-time online statistics of inventory, timed statistics of incoming and outgoing traffic; direct generation of financial statements. PreventStop financial counterfeiting, use inventory as a reservoir of profitability to adjust factory profits and losses.

Online monitoring

3D online monitoring of material level in each silo; can participate in the chain control system, applicable toAll kinds of silo material level monitoring, material quantity monitoring and measurement, etc.

Material surface visualization

The computer collects the measurement data to form a 3D visualization graph for the monitor to intuitively grasp the material.Warehouse Inventory

Historical storage monitoring

Through the software historical curve, historical data can check and analyze whether the material in and out is normal.Realize the effective monitoring of the financial situation of the group headquarters on the branch warehousing.

Product Specification

I. Technical parameters

| model number | KD-3D-05 Radar Level Scanner |

| antennae | lens antenna |

| Measuring principle | FM continuous wave, HF 120GHZ, 360° scanning measurement mode |

| Measurement accuracy per channel | ±2mm |

| Measurement range | 0.3-100m/customized for different bins from 2m-100m. |

| environmental temperature | -40 ℃~85 ℃ |

| response time | Power-up time to output valid measurement data <20S |

| Fastest measurement data update time <10S | |

| protection class | IP67 |

| input voltage | 24VDC |

| signal output | 4-20mA (4-wire) |

| communication protocols | RS485 |

| Digital Signal Output Interface | Modbus RTU |

| HART | |

| 4G Bluetooth(Optional) | |

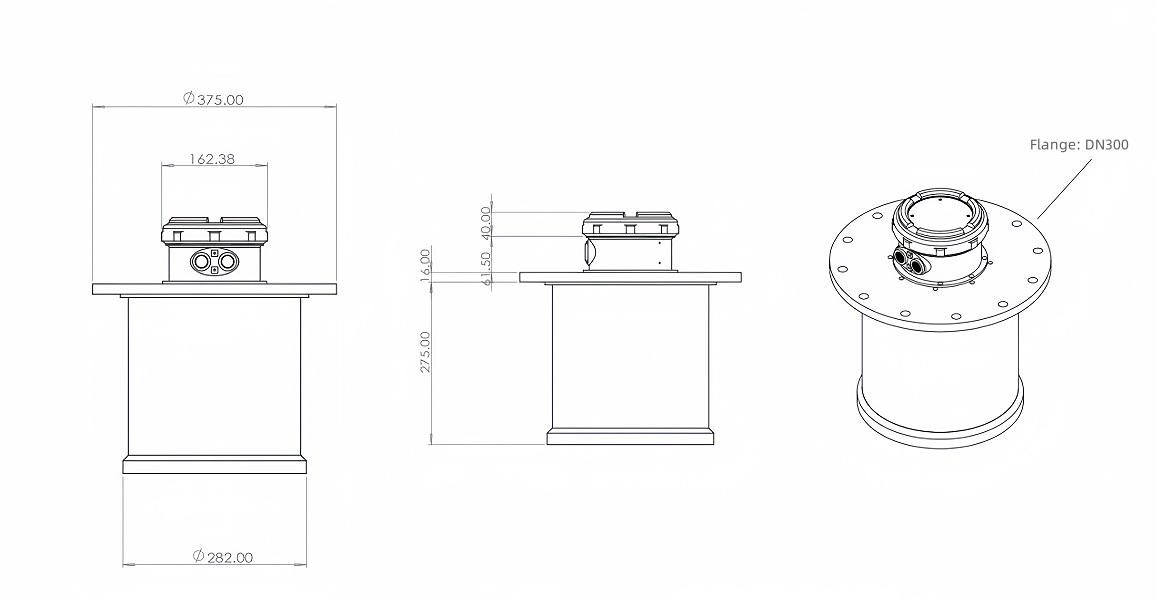

| Installation | DN250 |

| Flange Material | 304 stainless steel |

| Hole Size | φ380mm |

| Explosion-proof symbol | Ex tb IIIC T135℃ Db |

II. Overall dimensions

Areas of application

The KD-3D-05 provides efficient bulk solids measurement and practical inventory management for bulk solids used in a wide range of industrial applications.process measurement and practical inventory management for bulk solids used in a variety of industrial applications. These devices provide practical measurements in a variety of containers, including including large open hopper silos, bulk solids storage chambers, stockpiles, and warehouses.These devices can practically measure any type of solids stored in a variety of vessels, including large open hopper bins, bulk solids storage chambers, stockpiles, and warehouses, as well as gradual build-up of material in silos, and many other challenging applications that could not be measured before.The KD-3D-05 has a maximum measuring range of 100 meters and can be used with multiple units without bins.The KD-3D-05 has a maximum measuring range of 100 meters and can be used in conjunction with multiple units with no bin diameter limitation.

● Volume measurement of grain, flour and solid additives

● Level and volume measurement of cement silos

● Level and volume measurement of large coal silos

● Volumetric measurement of polypropylene

● Volume and level measurement of baking soda in silos

● Volume measurement and control of metal ores

● Volumetric measurement of dry solids in silos

Installation and commissioning

I. Radar installation

The radar is designed for field installation and the ambient temperature should be within the specified range.The ambient temperature should be within the specified range. However, the radar should be installed as far as possible from shaking, corrosive air and corrosive atmospheres and where mechanical damage may occur. The instrument should preferably be installed The instrument should preferably be installed in an area with an operating platform that is protected against lightning.When the radar antenna transmits pulses, there is a certain transmitting angle from the lower end of the antenna to the measured medium.Between the lower end of the antenna and the surface of the measured medium, there should be no obstacles in the area radiated by the transmitted beam.There should be no obstacles in the area radiated by the transmitted beam from the lower end of the antenna to the surface of the measured medium, so the installation should be avoided as far as possible.Tank facilities such as man-lifts, limit switches, heating equipment, stands, etc. The highest material level should not enter the blind zone of measurement.The power supply should preferably be 24VDC linear regulated power supply with peak noise not greater than 50mV.Do not share the power supply with pumps, motors or solenoid valves. Shielded cables are recommended for field cables and should not be used in parallel with AC cables over long distances.The field cable is recommended to use shielded cable, and can not be wired in parallel with the AC cable for a long distance. Radar protective ground should be connected to the standard earth or meter ground.The cross section area of the grounding conductor should not be less than 4mm2 .

II. Software Installation

server (computing)

| processing unit | IntelTM Dual Core and above |

| RAM | At least 1 GB |

| hard disk | At least 1GB of free space per year |

| Graphics card resolution | Minimum 1024x768 |

| connector | Ethernet NIC Card, Serial Port, USB Port |

| operating system | |

client (computing)

| processing unit | IntelTM Dual Core and above |

| RAM | At least 1 GB |

| hard disk | At least 1GB of free space per year |

| Graphics card resolution | Minimum 1280 x 1024 |

| connector | Ethernet NIC card, CD-ROM drive or USB port |

| operating system | Windows XP(SP2) or Windows 7 |

| Framework | Microsoft .NET framework 4.0 |

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist