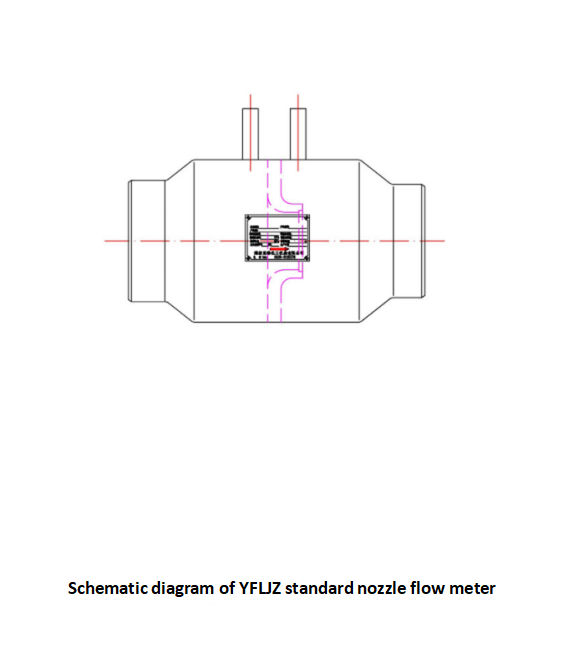

Nozzle flowmeter is to measure the flow of differential pressure generating device, with a variety of differential pressure meter or differential pressure transmitter can measure the flow of various fluids in the pipeline. Nozzle flowmeter can be divided into standard nozzle and long diameter nozzle flowmeter, standard nozzle flowmeter also known as ISA1932 nozzle, with high temperature and high pressure, impact resistance, large measuring range, measurement accuracy and other characteristics, suitable for high temperature and high pressure steam heat network pipeline in the power plant high flow rate of fluid measurements, the standard nozzle belongs to the standard throttling device, according to the national GB/T2624.1-2006 design and manufacture, according to JJG640-2016 for calibration without real-flow calibration, the standard nozzle is a standard throttle device, according to the national GB/T2624.1-2006 design and manufacture. According to JJG640-2016 for verification without real flow calibration. Measurement principle is based on the fluid mechanics of throttling principle, full of fluids in the pipeline, when they flow through the pipeline nozzle, the flow rate will form a local contraction in the nozzle, thereby accelerating the flow rate, so before and after the nozzle will produce a pressure drop or called the pressure difference, the greater the flow rate of the media flow, the greater the pressure difference generated in front of and behind the nozzle, so you can measure the size of the fluid flow rate through the measurement of the pressure difference. According to customer demand can be customized with root valve, three valve group, differential pressure transmitter and so on.

➱Suitable for measuring high temperature steam flow measurement

➱There are relevant national standards, no need for real-flow calibration

➱ Pressure loss is better than orifice flow meter

➱Measurement accuracy is better than 0.5 level

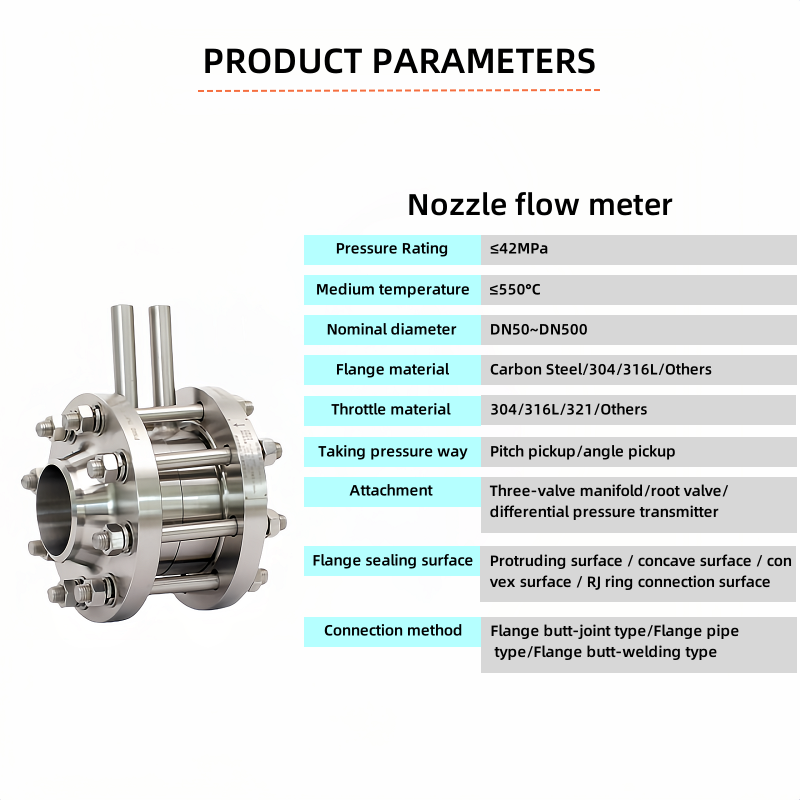

| Nominal diameter | DN50~DN500 | Aperture ratio | 0.30≤β≤0.8 |

| Nominal pressure | PN≤42MPa | Precision | 0.5 level |

| Model | illustrate | |||

| YFLJZ | kaidi KDthrottling device | |||

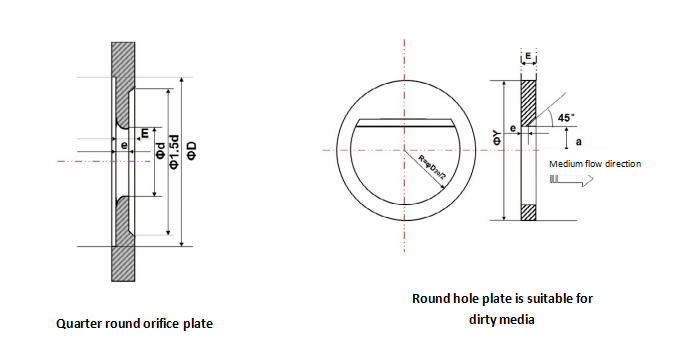

| Throttling device | B | Standard orifice | Q | Round hole plate |

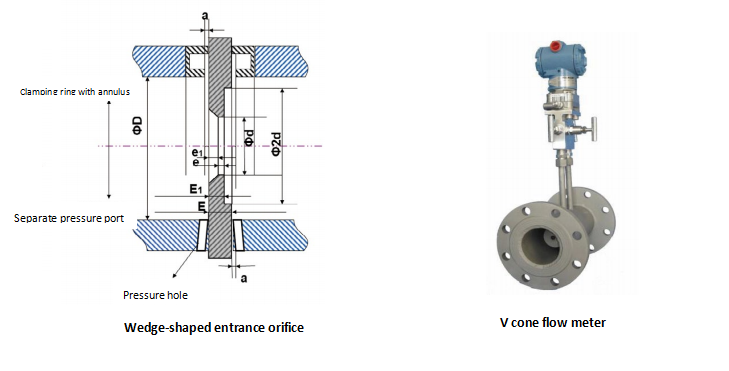

| P | Balance orifice/adjustment orifice | G | Wedge | |

| V | V cone | Z | nozzle | |

| X | Flow-limiting orifice (not used with metering, only used for current limiting or pressure reduction) | W | Venturi | |

| Caliber | -X | X pipe diameter is expressed by Arabic numerals, for example, DN100mm can be expressed as -100 | ||

| Pressure | -1.6 | 1.0 1.6 2.0 2.5 4.0 6.3 6.3 or more | ||

| Pressure taking method | F | Flange pressure (flange to clamp type) | ||

| J | Angle connection pressure (flange to clamp type) | |||

| D | Ring type pressure (flange to clamp type) | |||

| H | Line spacing pressure (pipeline integrated) | |||

| Flange form | WN | Butt welding flange with neck | ||

| SW | Plate socket welding flange | |||

| Flange material | C | Carbon steel | ||

| P | 304 | |||

| PL | 316L | |||

| T | Other materials | |||

| Throttle material | P | 304 | ||

| P1 | 321 | |||

| PL | 316L | |||

| T | Other materials | |||

| Attachment | 0 | NO | Y | Pressure transmitter (pressure compensation) |

| L | Condenser | J | Flow meter Totalizer | |

| F | Pressure valve | C | Differential pressure transmitter | |

| S | Three valve group | T | other | |

| W | PT100 (temperature compensation) | |||

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist