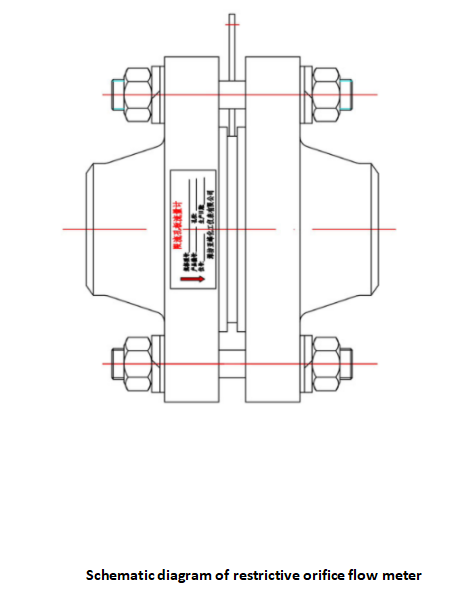

YFLJX series restrictor orifice plate is a concentric orifice plate, used to limit the flow of fluid or reduce fluid pressure. The fluid passing through the orifice plate will produce a pressure drop, and the flow rate through the orifice plate will increase with the increase of the pressure drop. But when the pressure drop exceeds a certain value, that is, exceeds the critical pressure drop, no matter how the outlet pressure decreases, the flow rate will maintain a certain value without increasing. The restrictor orifice is used to limit the flow of the fluid or reduce the pressure of the fluid according to this principle

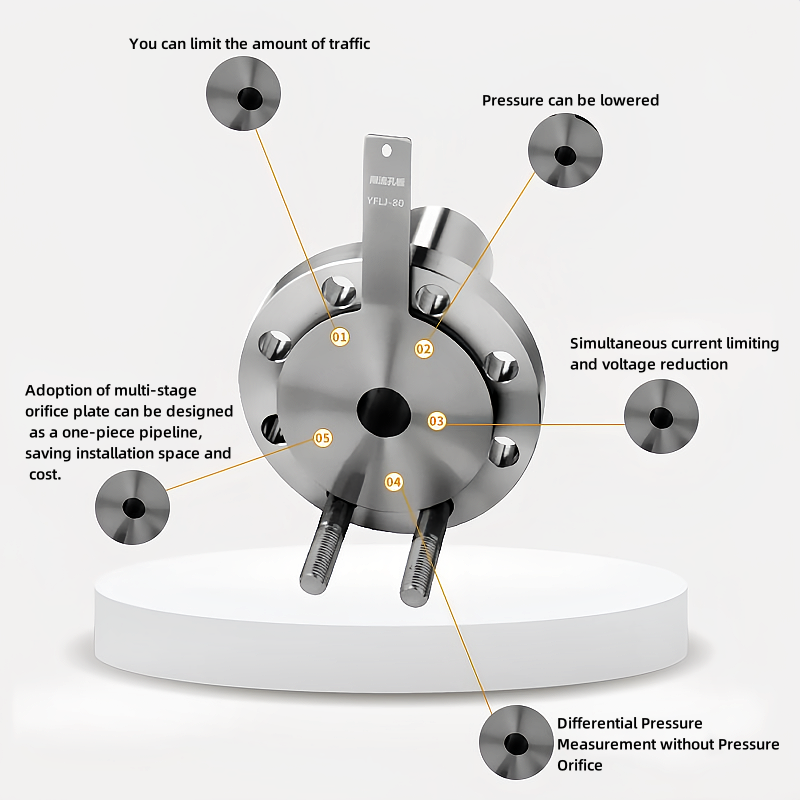

▲ Flow can be limited

▲ Can reduce stress

▲ Simultaneous current limit and pressure reduction

▲ No need to take pressure hole to measure differential pressure

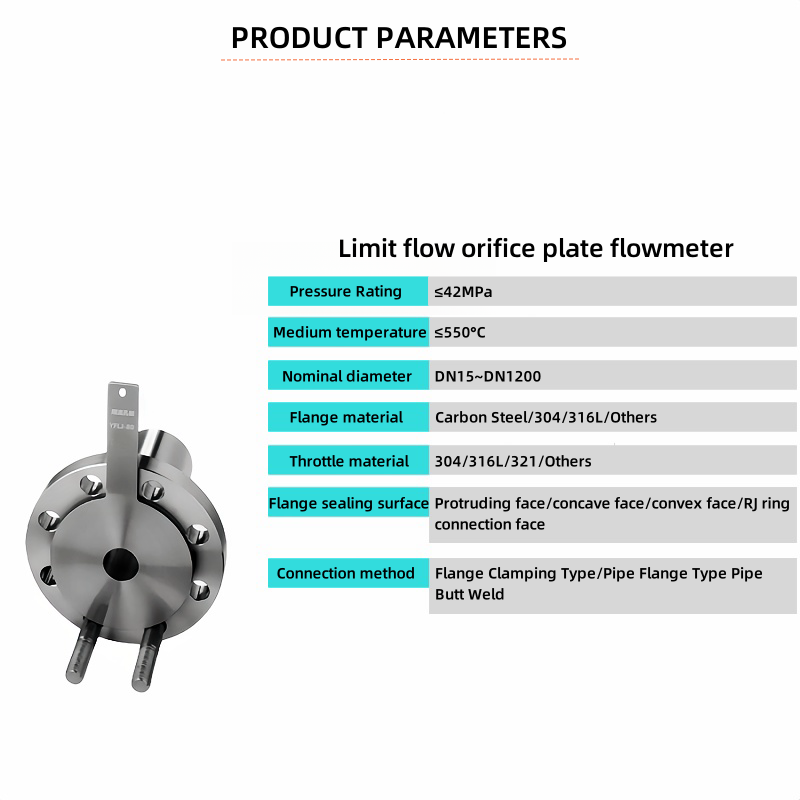

| Measuring medium | Liquid, gas, steam, mixed phase flow | Turndown ratio | 1:10,1:15 |

| Measuring caliber | 15 mm≤DN≤1200mm | Measurement accuracy | 0.5 level |

| Nominal pressure | PN≤42MPa | Material | Can be selected according to the measurement medium |

| Temperature range | -50°C≤t≤550C | ||

| Classification | Encoding rules | illustrate | ||

| Series | KD-YFLJ | kaidi restrictor orifice | Buck current limit | |

| Caliber | -X | X stands for caliber specification | DN15-1200 such as DN100, can be expressed as -100 | |

| Pressure Level | 1 | PN10 | 2 | CL150LB |

| 1.6 | PN16 | 5 | CL300LB | |

| 2.5 | PN25 | 11 | CL600LB | |

| 4 | PN40 | 15 | CL900LB | |

| 6.3 | PN63 | 26 | CL1500LB | |

| 10 | PN100 | 42 | CL2500LB | |

| 16 | PN160 | |||

| 25 | PN250 | |||

| Flange material | Omit | When the wafer type does not need a matching flange | ||

| C | Carbon steel | |||

| P | 304 | |||

| PL | 316L | |||

| T | Other materials | |||

| Sealing surface | Omit | Raised face | FM | Concave |

| M | Convex | RJ | Ring connection surface | |

| Connection method | D | Flange to clamp | ||

| H | Pipe flange type | Pipeline flange connection | ||

| Y | Pipe butt welding | Pipeline butt welding structure without flange | ||

| Throttle material | P | 304 | ||

| P1 | 321 | |||

| PL | 316L | |||

| T | Other materials | |||

| Throttle plate number | -X | X represents the number of stages | Suitable for pipeline type, flange to clamp type omitted | |

KAIDI Sensor,which is a professional level transmiter manufacturer with 20 years of experiences, is dedicated inproviding complete customized solutions for a wide range of industrial automation process applications --inmaterial level, liquid flow, pressure and temperature. We are constantly developing and innovating, our core vision“to provide solutions that exceed customers' expectations.

In 2012, the company successfully expanded its operations both locally and interationally, achieving globalsuccess and recognition for quality fork type level switch, rotary level switch, magnetic level gauges products andservices.

With emphasis placed on customer satisfaction, innovation, product development and overall businesstransformation, the company continued to innovate and expand with each passing year. As a level indicatormanufacturer, KAIDI Sensor has successfully achieved global recognition, obtaining the leading position as Asia'stop process automation sensor and level gauge manufacturers. These were implemented successfully, and KaidiSensors products,such as rotary level sensor and Level Indicator, can be used in many different industries suchas food & beverage, water, energy, pharmaceutical etc. In the past 5 years, the company has undergonetremendous growth and development - flourishing internationally and providing customers worldwide with thebest customized solutions for process automation

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.