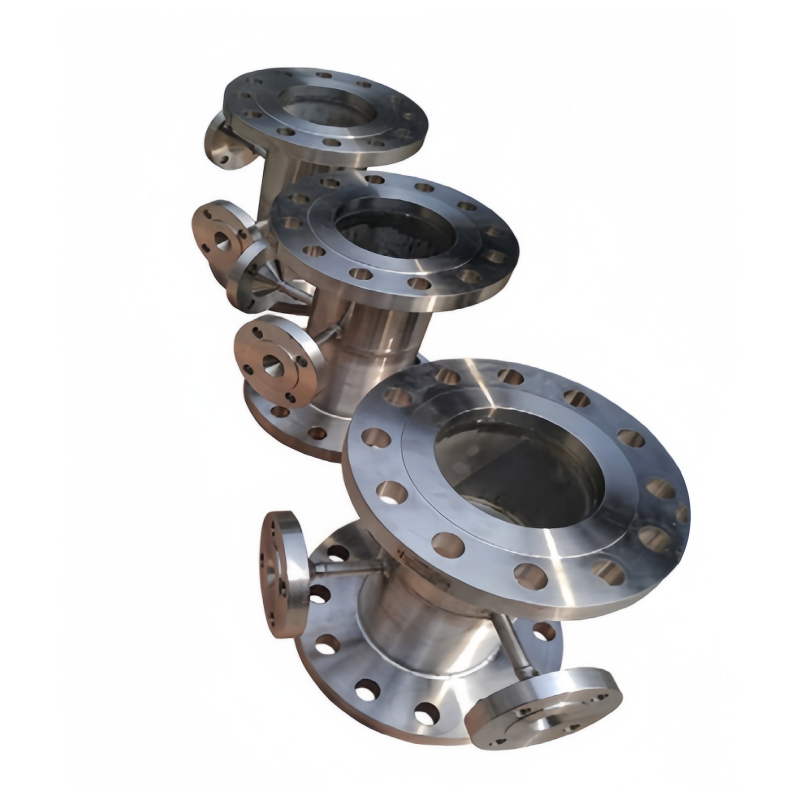

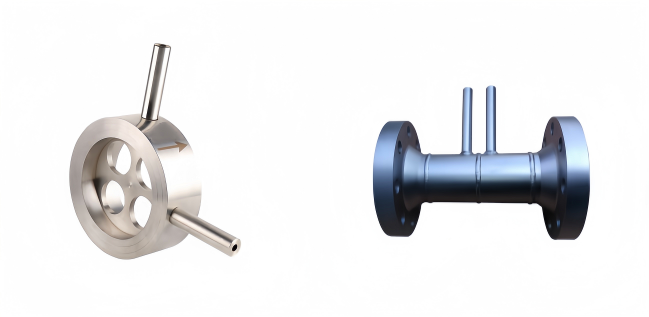

Balanced orifice flow meter is also called adjustment flow meter, multi-void orifice flow meter. It is an upgraded version of conventional orifice flow meter. The size and distribution of the holes are customized based on special formulas and test data, which are called function holes. When the fluid passes through the function hole of the disc, the fluid will be balanced and rectified, and the vortex will be minimized to form an approximate ideal fluid. Through the pressure taking device, a stable differential pressure signal can be obtained. The volumetric flow rate, Mass Flow.

✮The measurement accuracy is better than 1.0 level

✮ Energy optimization, saving the energy loss of the entire pipeline system

✮ The rectification function makes the front and rear straight pipe sections shorter

✮ Greatly reduce pressure loss

✮ Increase the thickness of the throttling device to enhance the straightening function

✮ Pressure method: flange pressure; corner joint pressure; ring chamber pressure; travel pressure, etc.

✮ Process connection method: butt welding, pipeline, flange to clamp, etc.

| Measuring medium | Liquid, gas, steam, mixed phase flow | Turndown ratio | 1:10, 1:15 |

| Measuring caliber | 15 mm ≤ DN ≤ 1200mm | Measurement accuracy | 0.5 grade, 1.0 grade |

| Nominal pressure | PN ≤ 42MPa | Temperature range | -50℃≤ t ≤ 550℃ |

| Material | Can be selected according to the measurement medium | ||

| Model | illustrate | |||

| YFLJ | kaidi throttling device | |||

| Throttling device | B | Standard orifice | Q | Round hole plate |

| P | Balance orifice/adjustment orifice | G | Wedge | |

| V | V cone | Z | nozzle | |

| X | Flow-limiting orifice (not used with metering, only used for current limiting or pressure reduction) | W | Venturi | |

| Caliber | #NAME? | X pipe diameter is expressed by Arabic numerals, for example, DN100mm can be expressed as -100 | ||

| Pressure | -1.6 | 1.0 1.6 2.0 2.5 4.0 6.3 6.3 or more | ||

| Pressure taking method | F | Flange pressure (flange to clamp type) | ||

| J | Angle connection pressure (flange to clamp type) | |||

| D | Ring type pressure (flange to clamp type) | |||

| H | Line spacing pressure (pipeline integrated) | |||

| Flange form | WN | Butt welding flange with neck | ||

| SW | Plate socket welding flange | |||

| Flange material | C | Carbon steel | ||

| P | 304 | |||

| PL | 316L | |||

| T | Other materials | |||

| Throttle material | P | 304 | ||

| P1 | 321 | |||

| PL | 316L | |||

| T | Other materials | |||

| Attachment | 0 | NO | Y | Pressure transmitter (pressure compensation) |

| L | Condenser | J | Flow meter Totalizer | |

| F | Pressure valve | C | Differential pressure transmitter | |

| S | Three valve group | T | other | |

| W | PT100 (temperature compensation) | |||

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.