1. Product Principle

The radar water level antenna emits extremely narrow microwave pulses that travel at the speed of light, and part of the energy is reflected back when it encounters the surface of the measured medium and is received by the same antenna. The time interval between the transmitted pulse and the received pulse is proportional to the distance from the antenna to the surface of the measuring medium. Due to the extremely high propagation speed of electromagnetic waves, the time interval between the transmitted pulse and the received pulse is very small (nanosecond order) and it is difficult to confirm. The high-frequency radar water level gauge uses a special demodulation technology that can accurately identify the transmitted pulse and the received pulse The distance between the antenna and the surface of the measured medium can be further calculated.

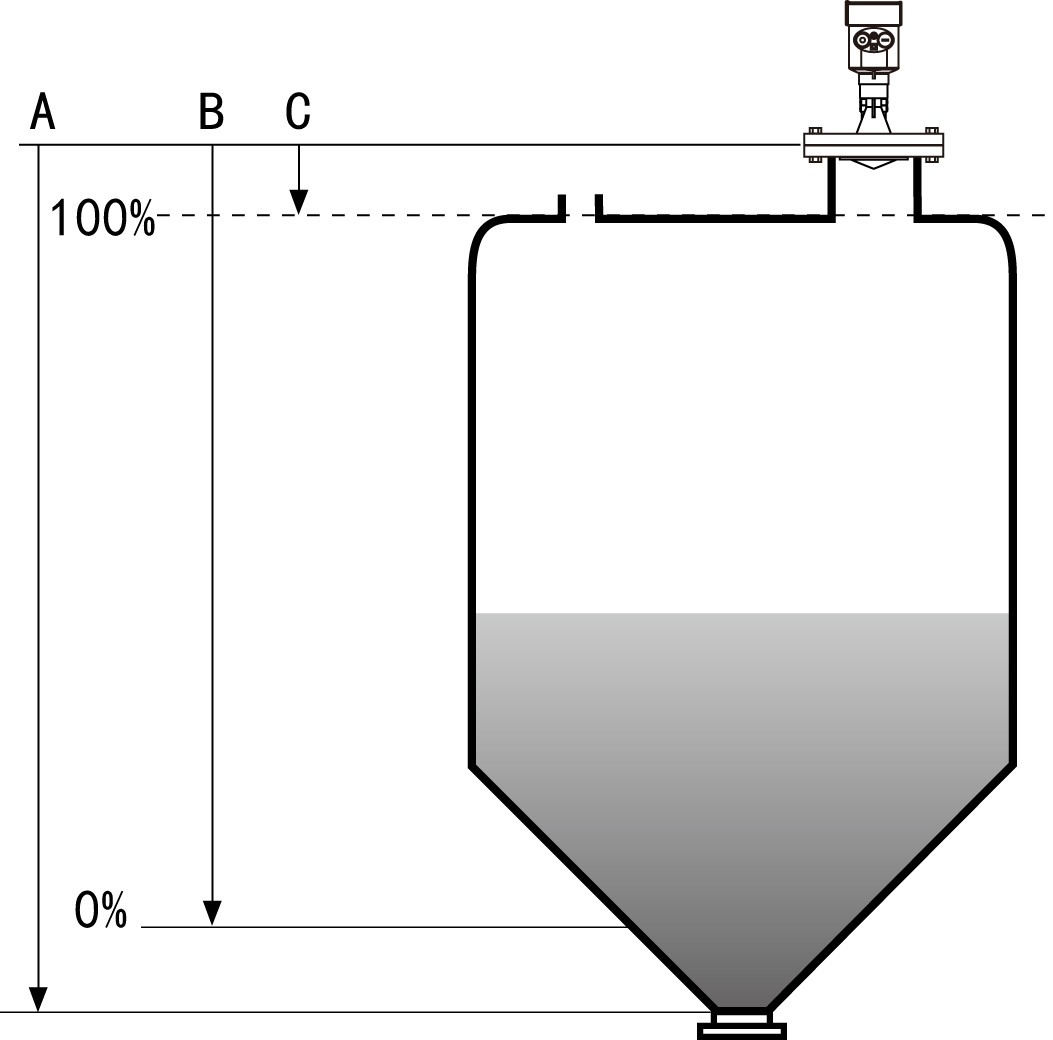

A Range set

B Low adjustment

C High adjustment

Datum measurement: Screw thread bottom or the sealing surface of the flange.

Note: Make sure the radar level meter the highest level cannot enter the measuring blind area (Figure D shown below).

Application characteristics

The radar water level gauge uses a 26GHz transmitting frequency and has:

Ø Small beam angle, concentrated energy, stronger anti-interference ability, greatly improved measurement accuracy

Ø The antenna is small in size, easy to install, and easy to add dust cover and other antenna protection devices

Ø Lighter weight, about 1KG, easy to install

Ø The maximum measurement range can reach 70 meters, which can cover water level measurement such as large reservoirs

Ø With a variety of output circuit interface and data acquisition system.

Ø The pulse working mode, radar level meter transmit power is very low, no harm to human body and environment.

2. Product Introduction

902F

3. The Installation Requirements

Installation Precautions:

Please pay attention to the following items to ensure that the meter can be installed correctly:

Please reserve enough space for installation.

Please avoid installation situations with strong vibration.

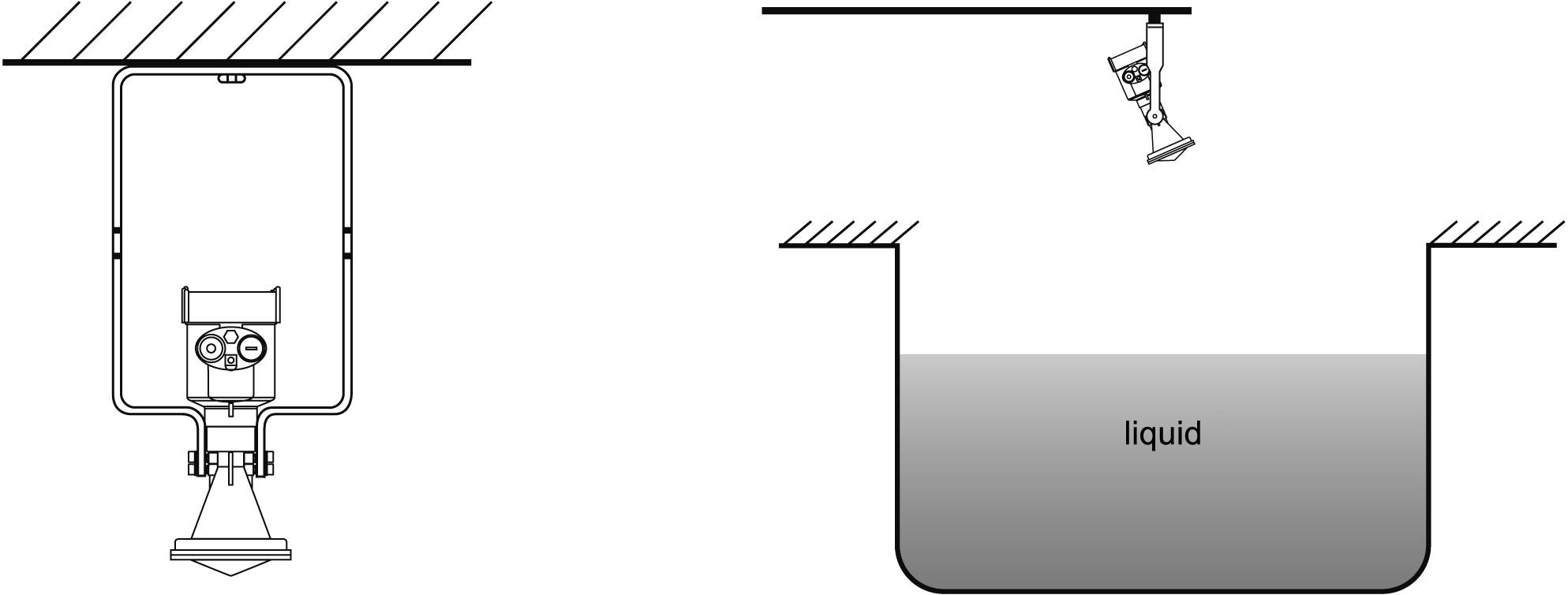

Dragon door frame installation

Flange installation

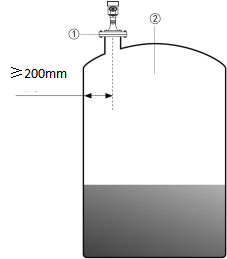

Gauges are installed at 1/4 or 1/6 of the diameter of the tank.

The minimum distance from the pipe wall is 200 mm.

Avoid installation in the center of the tank.

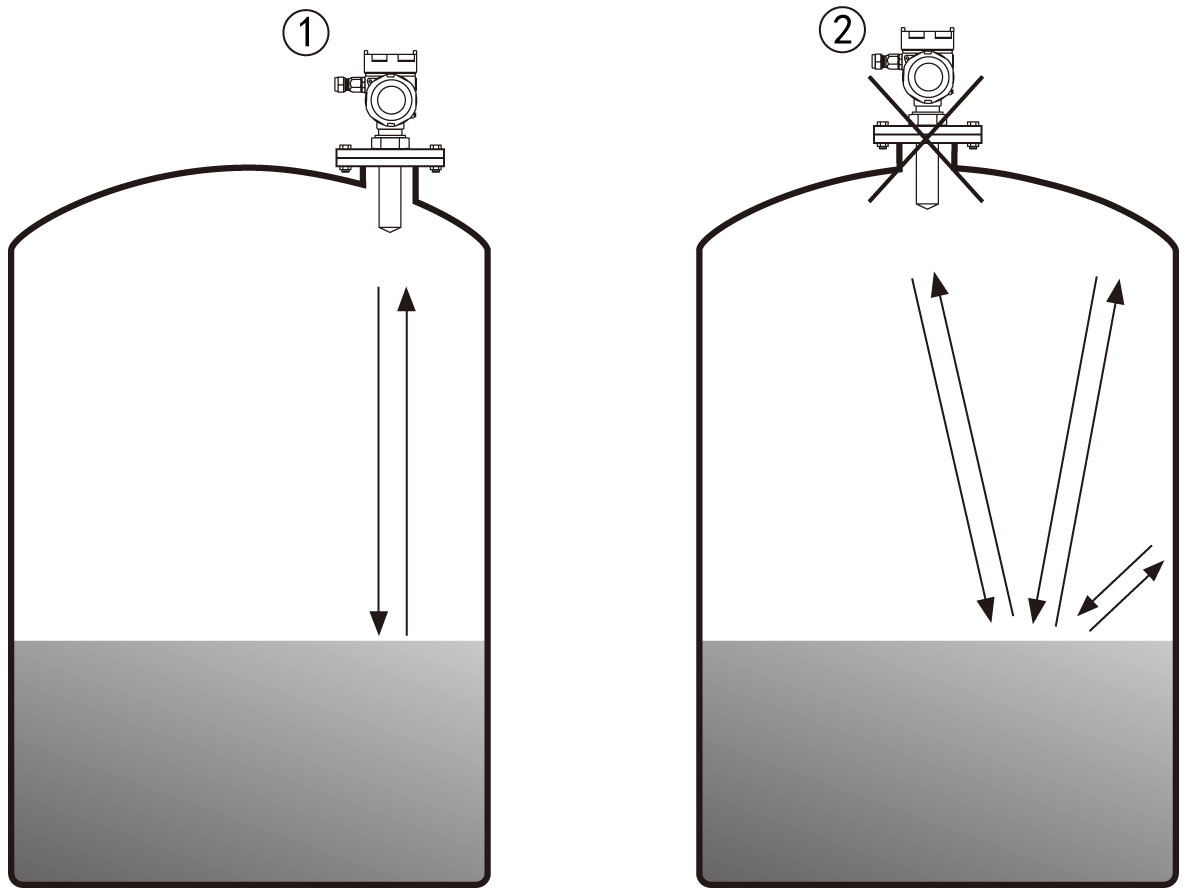

Typical installation errors:

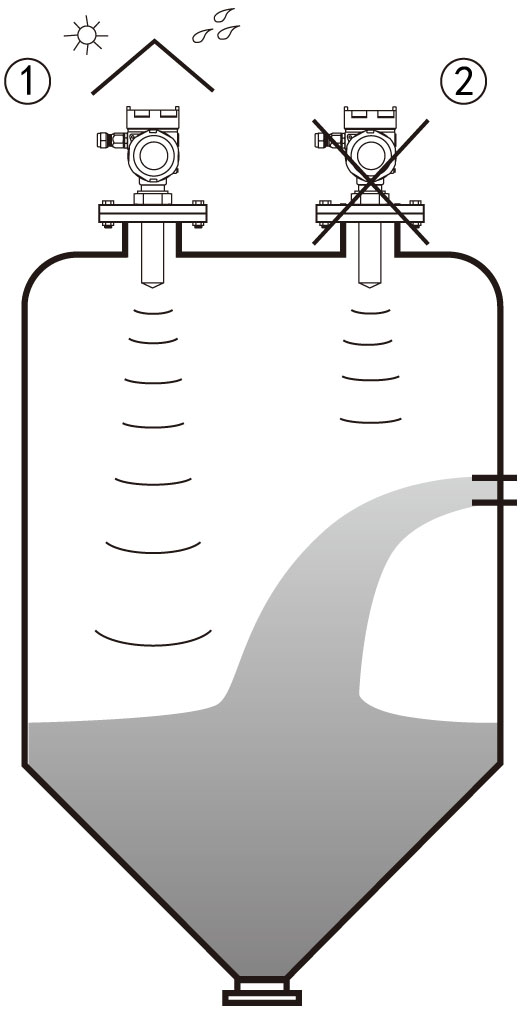

Ø Conical tank

The instrument cannot be installed above the inlet.

Note: Sun-shading and rain-proof measures should be taken during outdoor installation..

①Correct ②Error rainproof measures

Ø The meter cannot be installed in the middle of the top of an arched or round tank. In addition to producing indirect echoes, it will also be affected by multiple echoes. Multiple echoes may be larger than the signal threshold of true echoes, because multiple echoes can be concentrated through the top, so they cannot be installed in the center.

①Correct ②Error

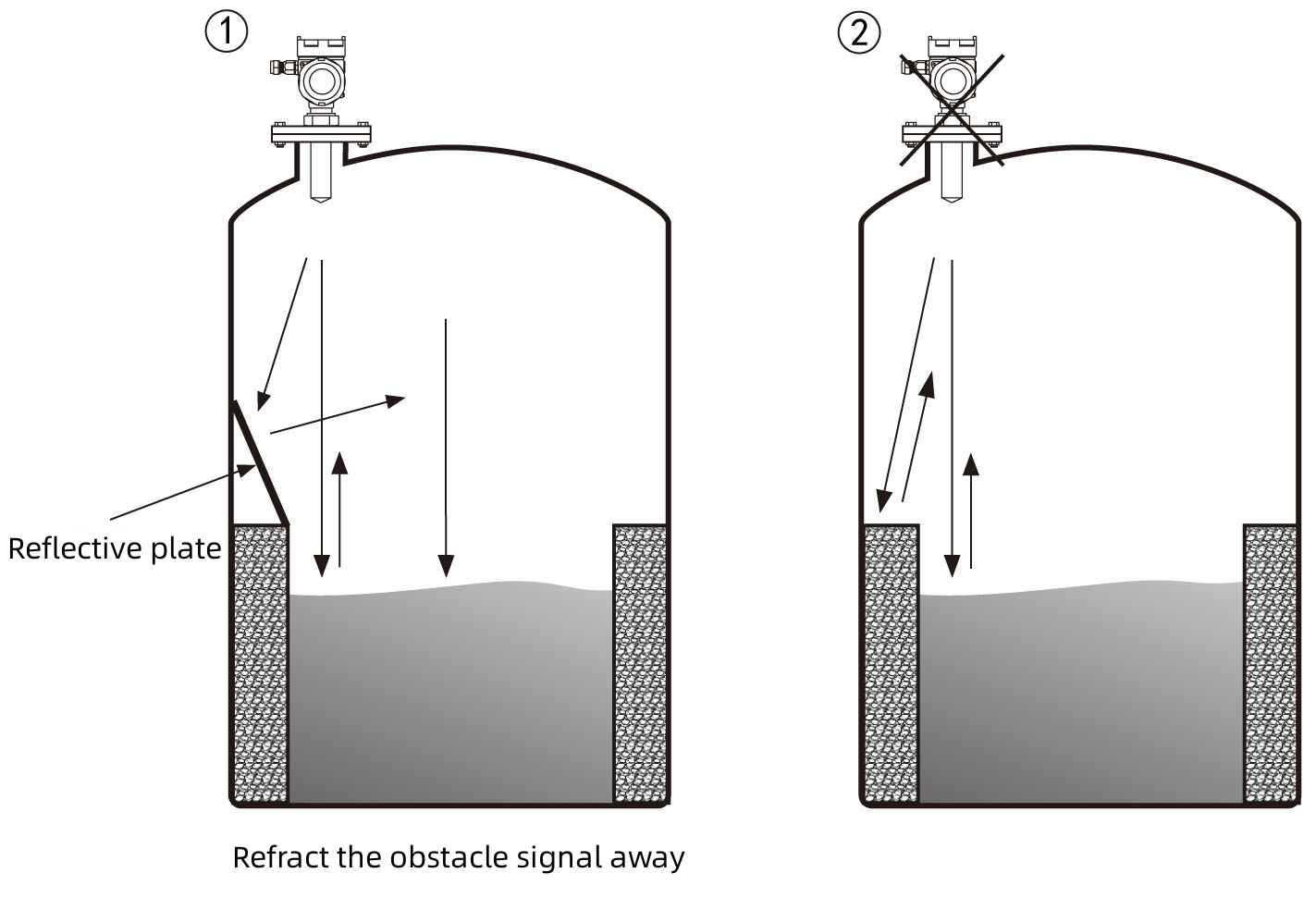

Ø When there are obstacles in the tank that affect the measurement, it is necessary to install a reflector to measure normally

①Correct ②Error

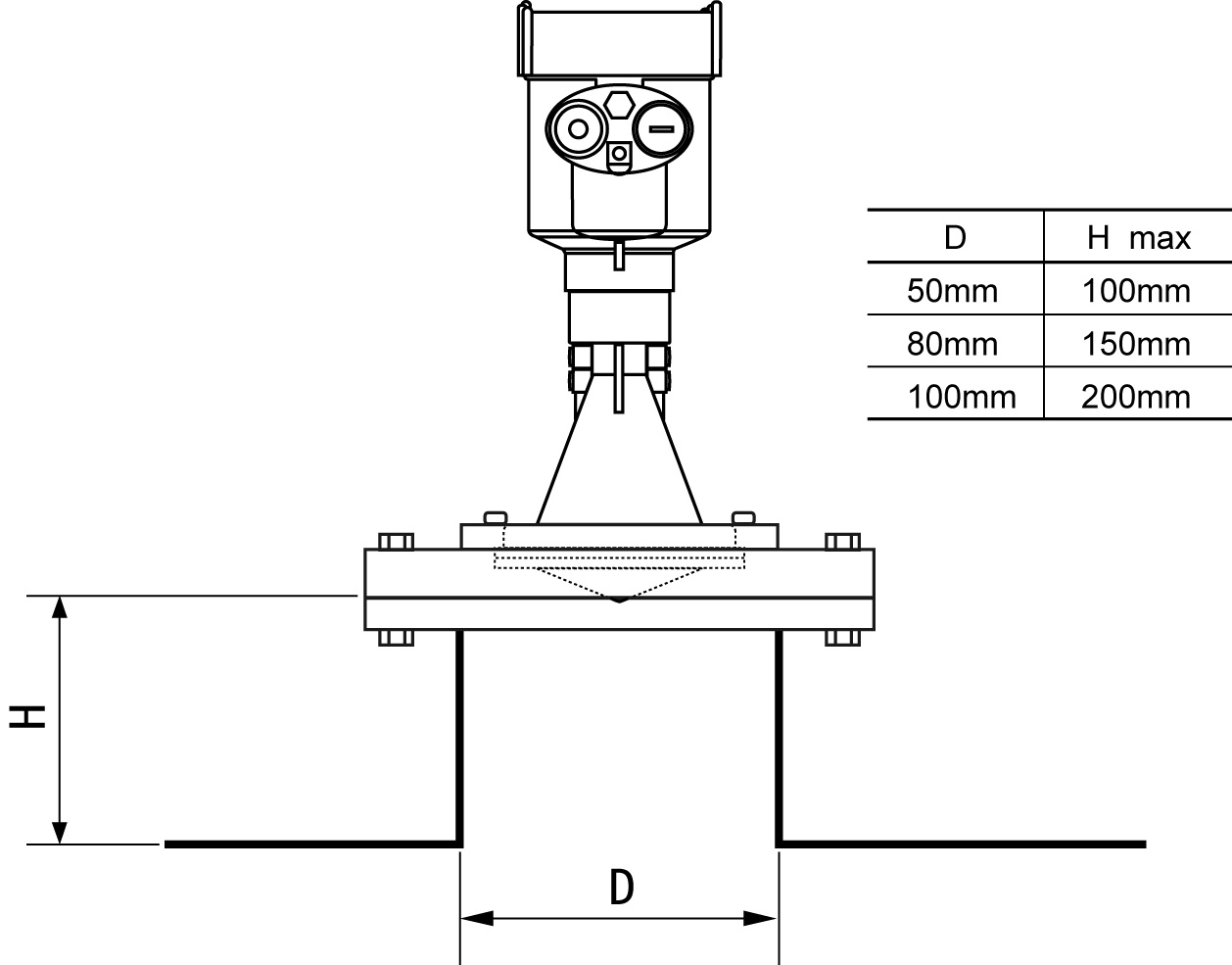

Container takeover requirement

Make sure that the antenna extends into the tank at least 10mm away.

4. The Electrical Connection

The power supply voltage:

(4~20)mA/HART (Two wire system) | The power supply and the output current signal sharing a two core shield cable. The supply voltage range see technical data. For intrinsically safe type must be a safety barrier between the power supply and the instrument. |

| (4~20)mA/HART(Four wire system) | Separate power supply and the current signal, respectively using a two-core shielded cable. The supply voltage range see technical data |

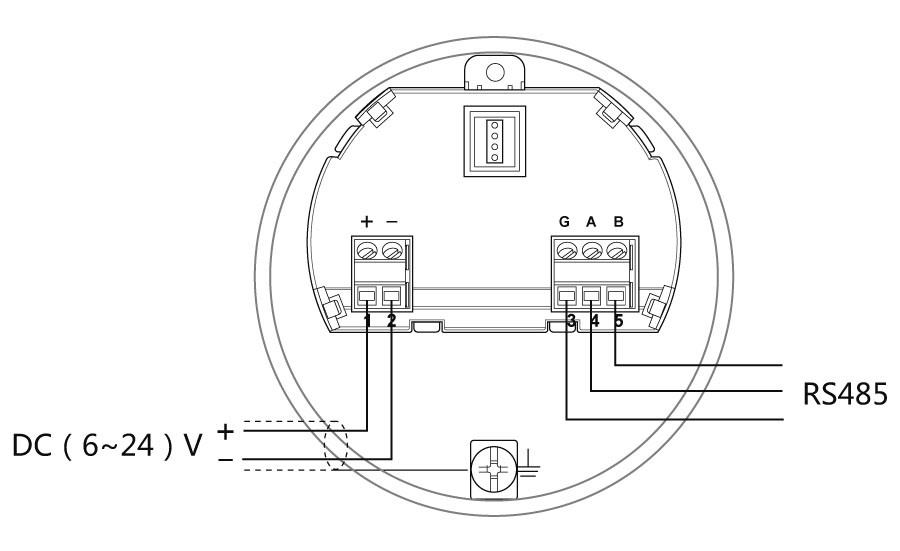

| RS485 / Modbus(Four wire system) | Power supply and Modbus signal line separated respectively using a two-core shielded cable, the power supply voltage range see technical data. |

Cable Connection

General Introduction | Supply cable can use ordinary two-core cable, the cable diameter should be (6~12) mm, to ensure that the cable entry seal. If electromagnetic interference exists, recommended to use shielded cable. |

(4~20) mA(4-wire / 6-wire) | The power supply needs to be powered separately. The power supply and current signals use a four-core shielded cable (current signal and RS485 interface can be output simultaneously, and a six-core shielded cable is required for output) |

Modbus-RS485 | The power supply needs to be powered separately. The power supply and digital use a four-core shielded cable (current signal and RS485 interface can be output simultaneously, and a six-core shielded cable is required for output). |

Connection mode

Ø The Modbus-RS485 wiring diagram as follows:

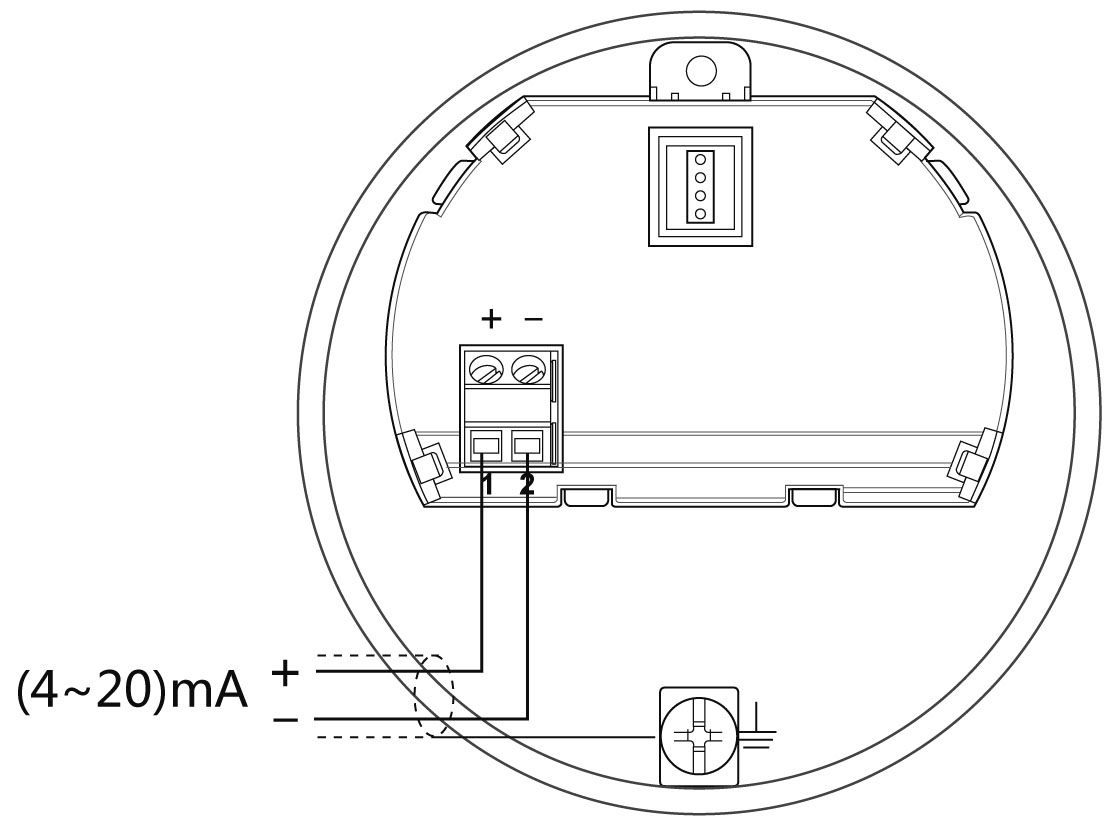

Ø 24V 2-wire wiring diagram as follows:

Safety instructions:

Ø Please observe the local electrical code requirements!

Ø Please comply with local requirements for personnel health and safety regulations.

All electrical components of instrument operation must be completed by the formal training of professionals.

Ø Please check the instrument nameplate to provide product specifications meet your requirements. Please make sure that the power supply voltage and instrument nameplate on the requirements.

Protection grade:

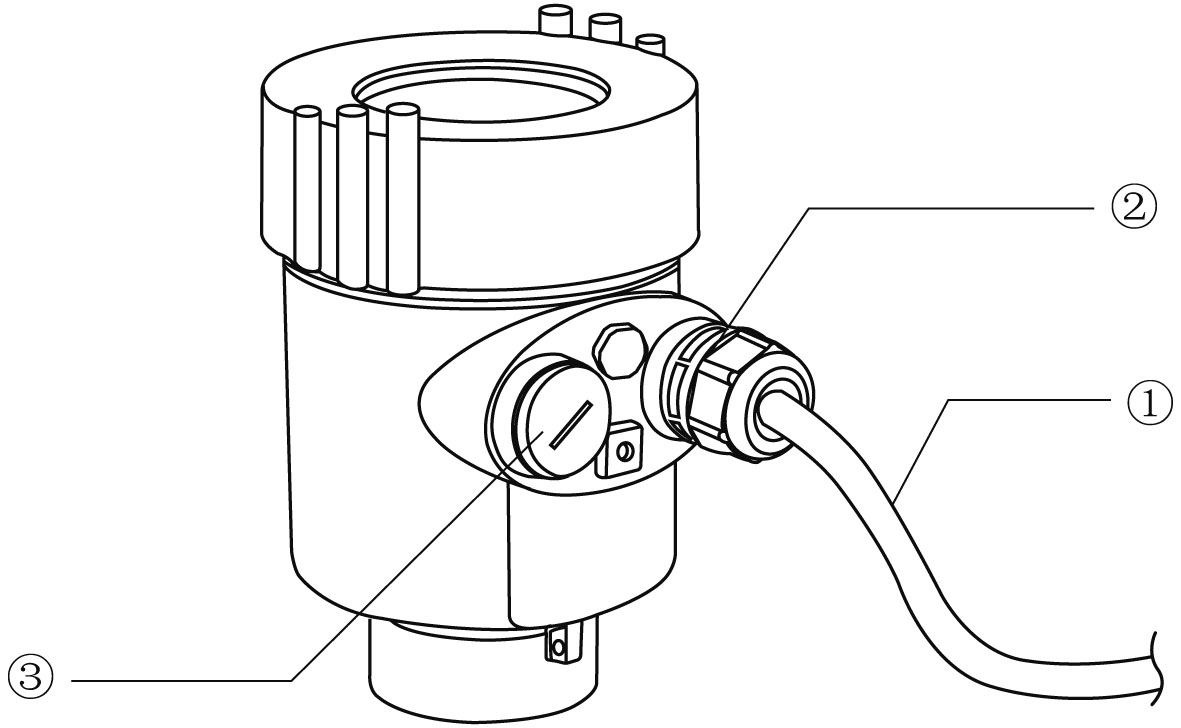

This instrument meets the protection class IP66/67 requirements, please ensure the waterproof cable sealing head. The following diagram:

How to install to meet the requirements of IP67:

Please make sure that the sealing head is not damaged.

Please make sure that the cable is not damaged.

Please make sure that the cable for use with electrical connection specification.

Cable into the electrical interface before its curved downward, ensure that the water will not flow into the shell, see the①

Tighten the cable seal head, see the②

Please electrical interface will not use blind plug tight, see the③

5. Instrument Commissioning

There are two kinds of debugging method:

1) Display / Button (With split display, you need to debug on the split)

2) Debug through computer software

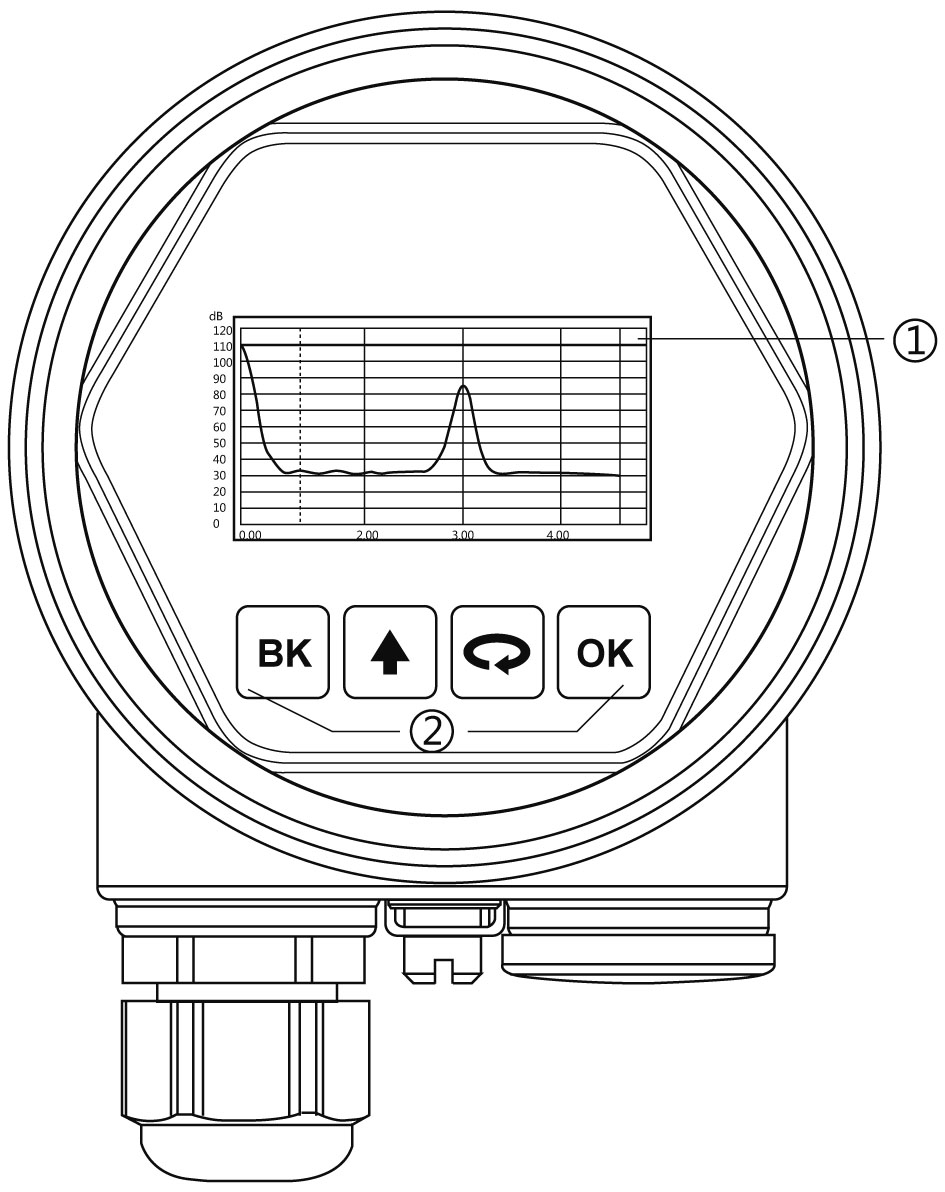

Display / Button:

Debug the meter through the 4 buttons on the display screen. The debugging menu has four languages to choose from. The measured value can be read very clearly through the glass window.

Display / Button

① Liquid crystal display(LCD)

② Adjust by button

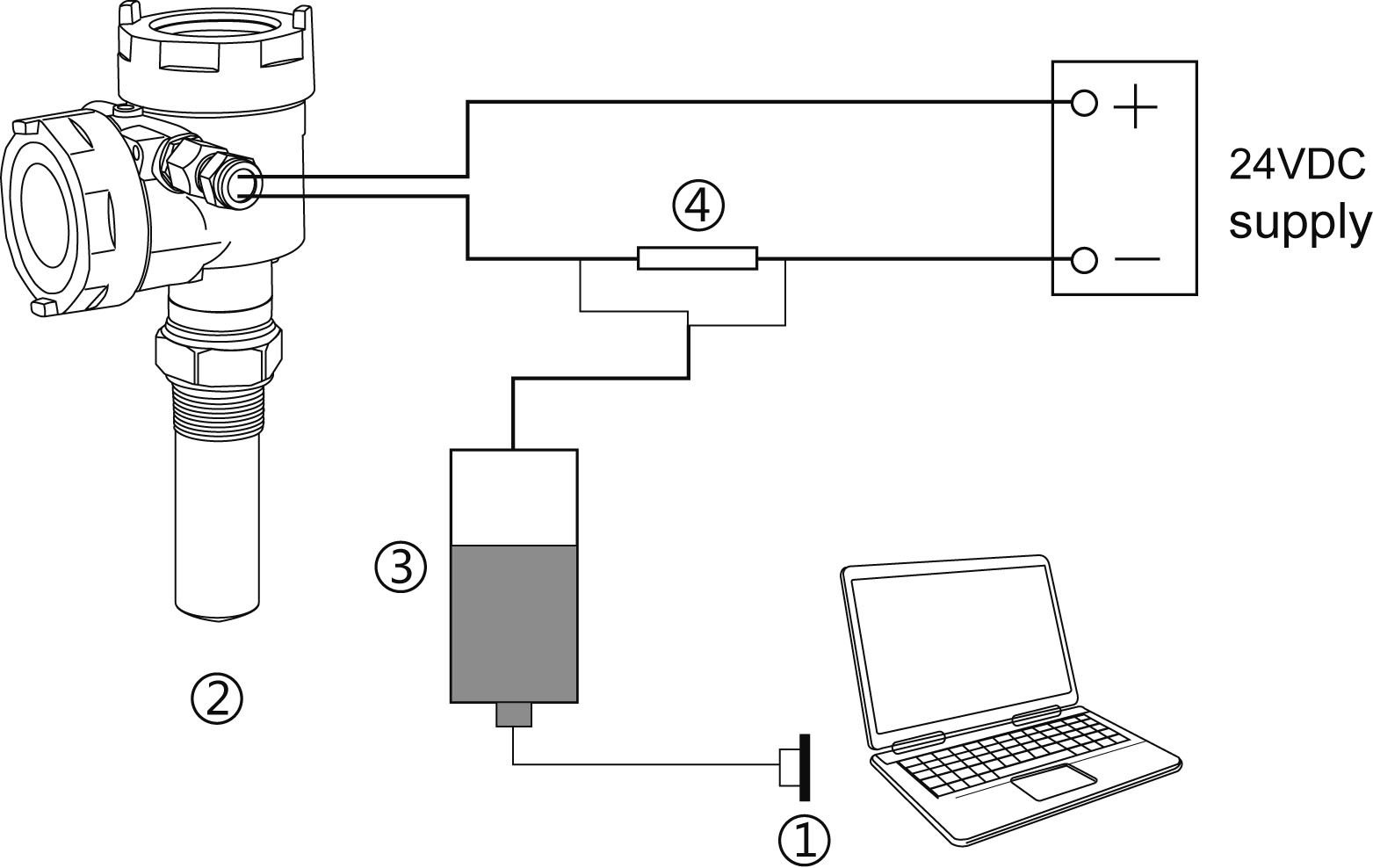

PC software debugging:

Connected to PC by HART

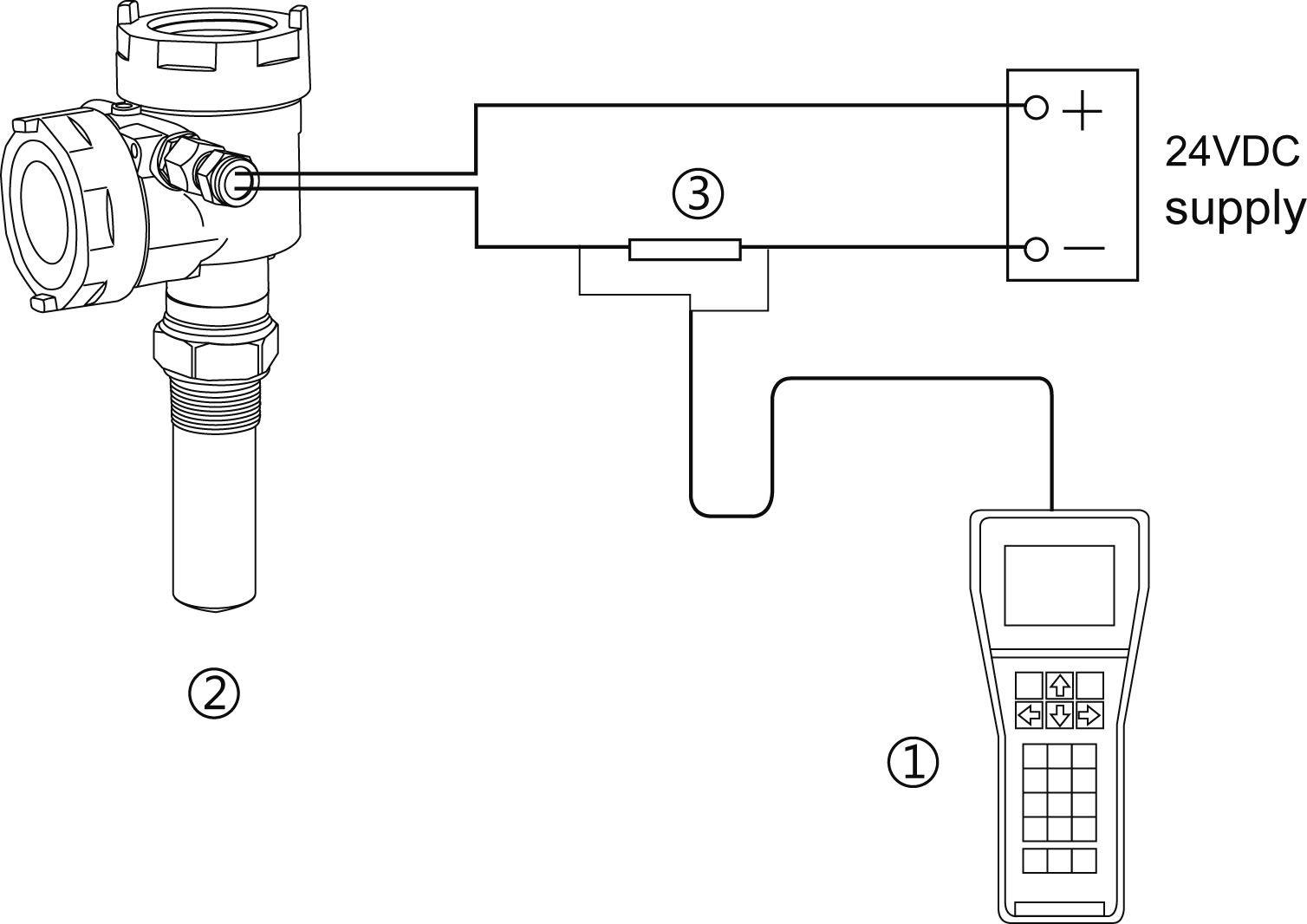

① USB interface ② Radar level meter ③ HART converter ④ 250 Ω Resistor

HART handheld programmer:

① HART handheld programmer ② Radar level meter ③ 250 Ω Resistor

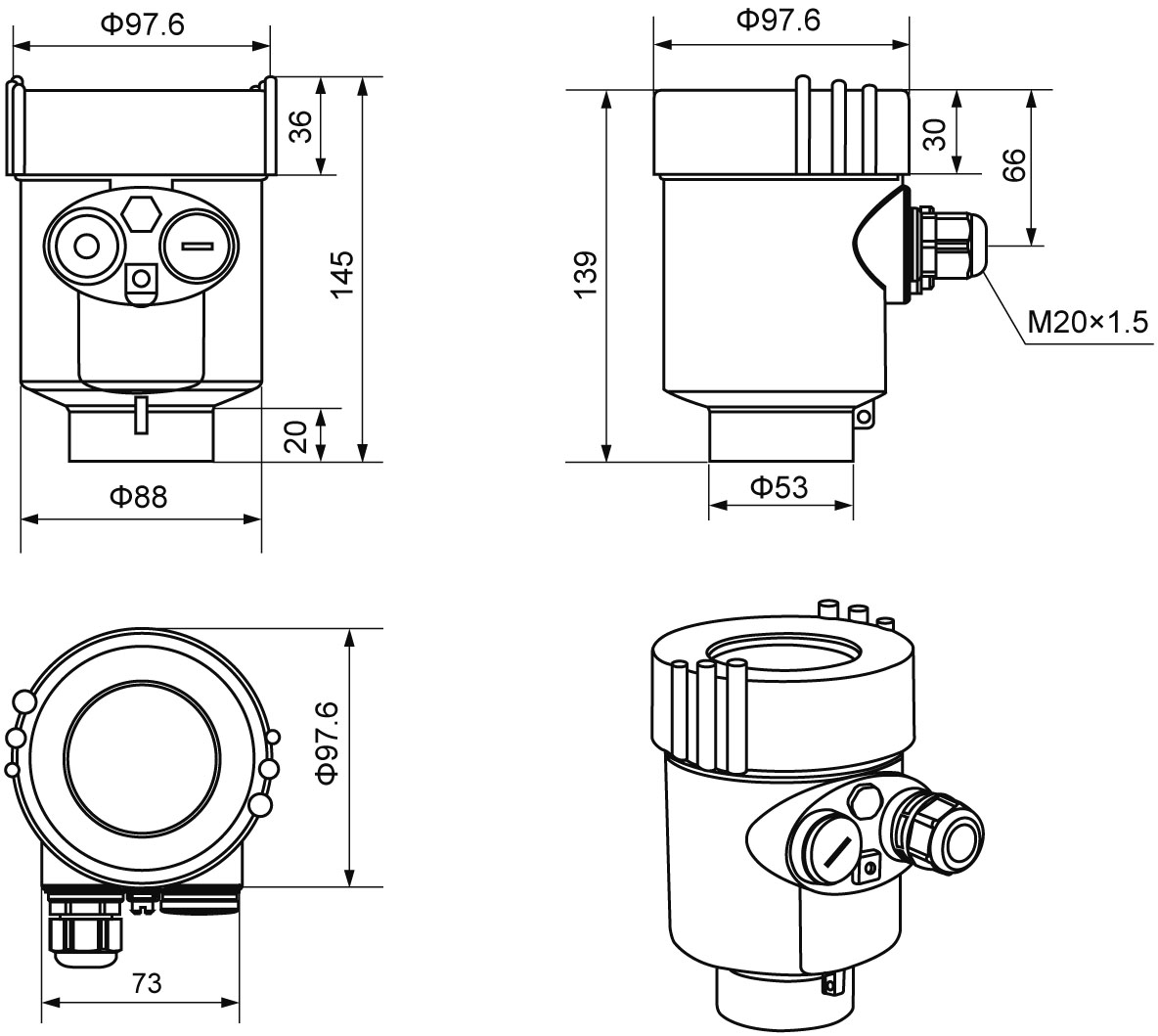

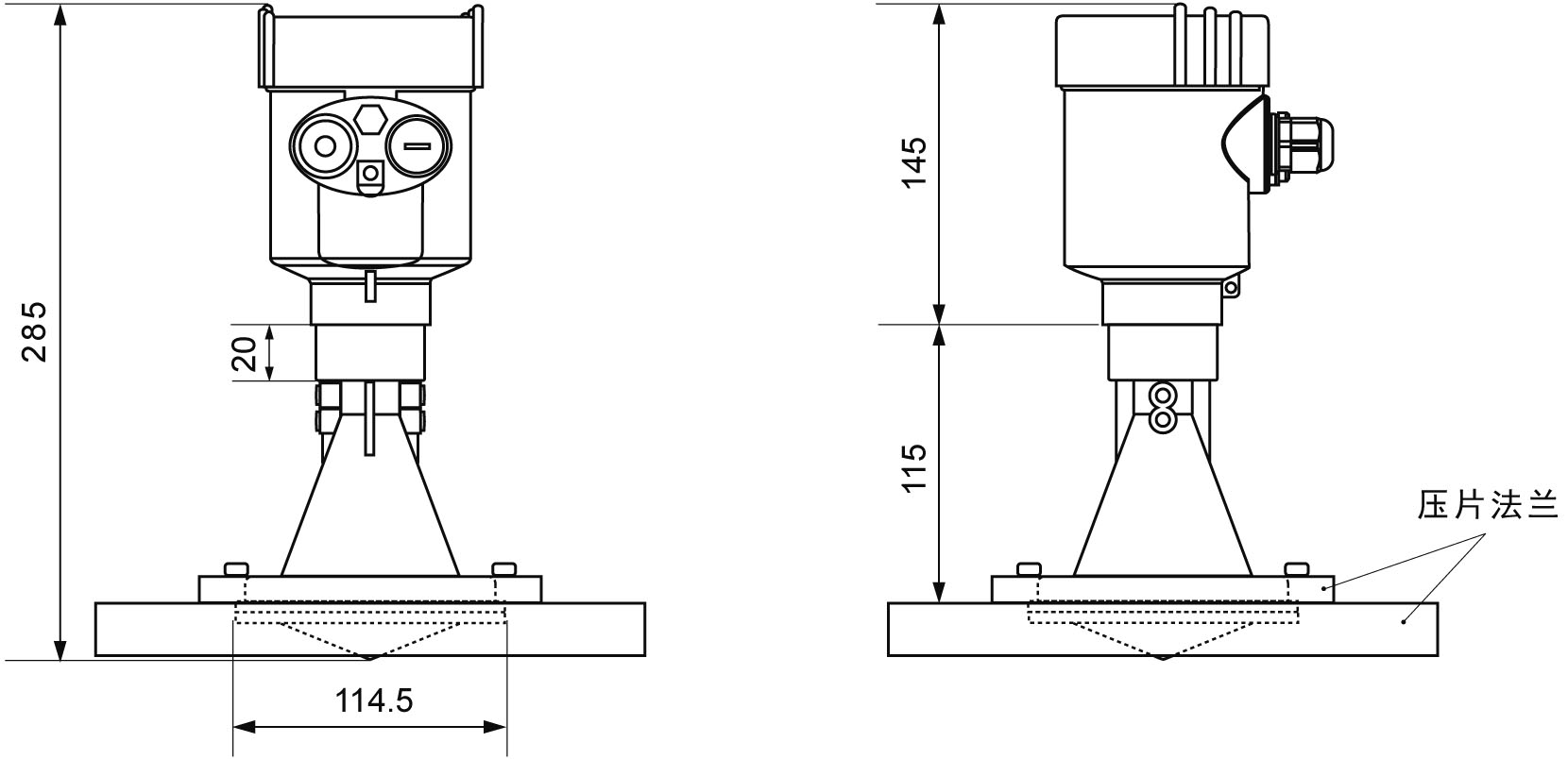

6. Structure Size (Unit: mm)

The Outer Covering:

Cast aluminum shell

Plastic shell

Product size:

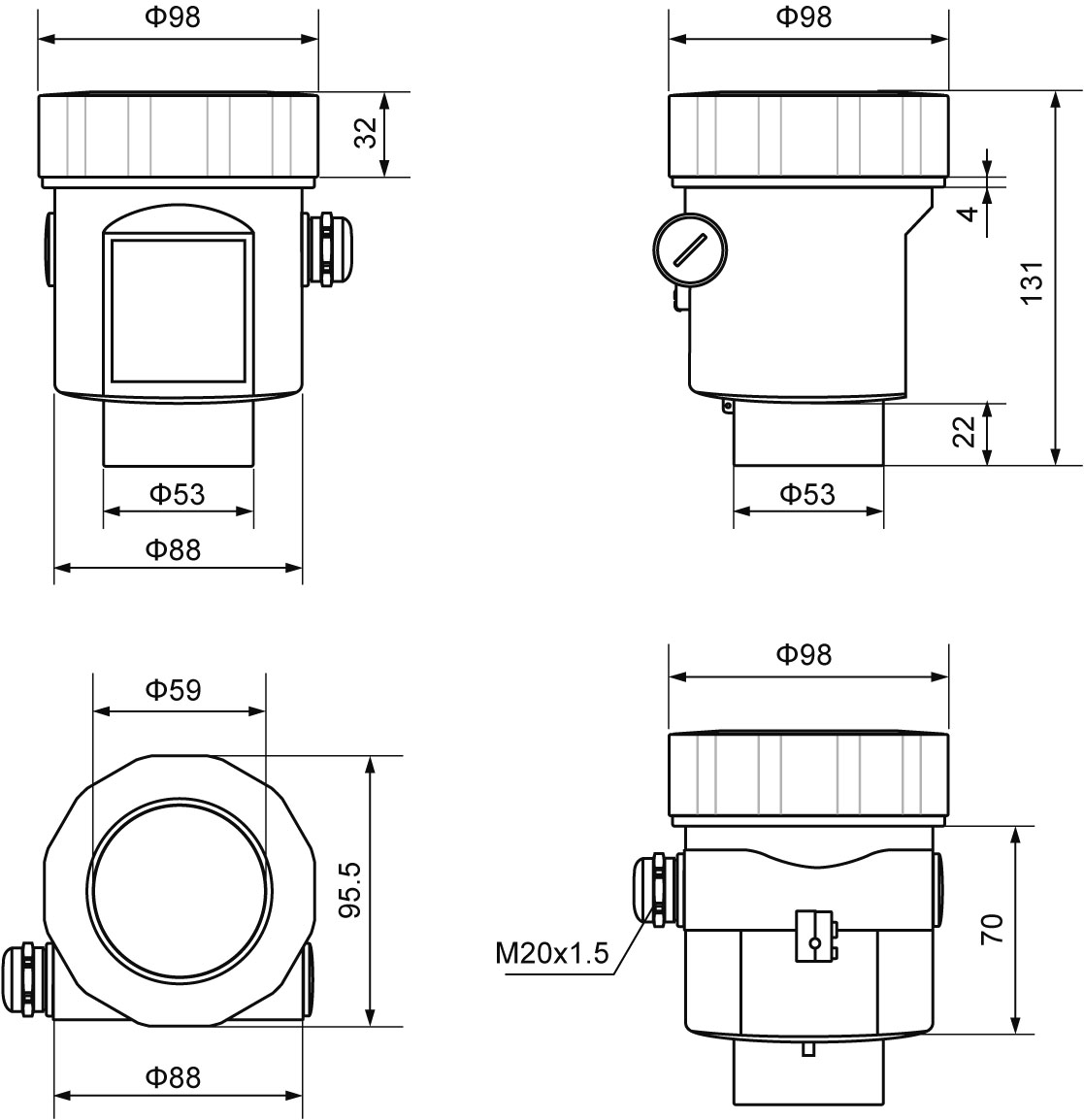

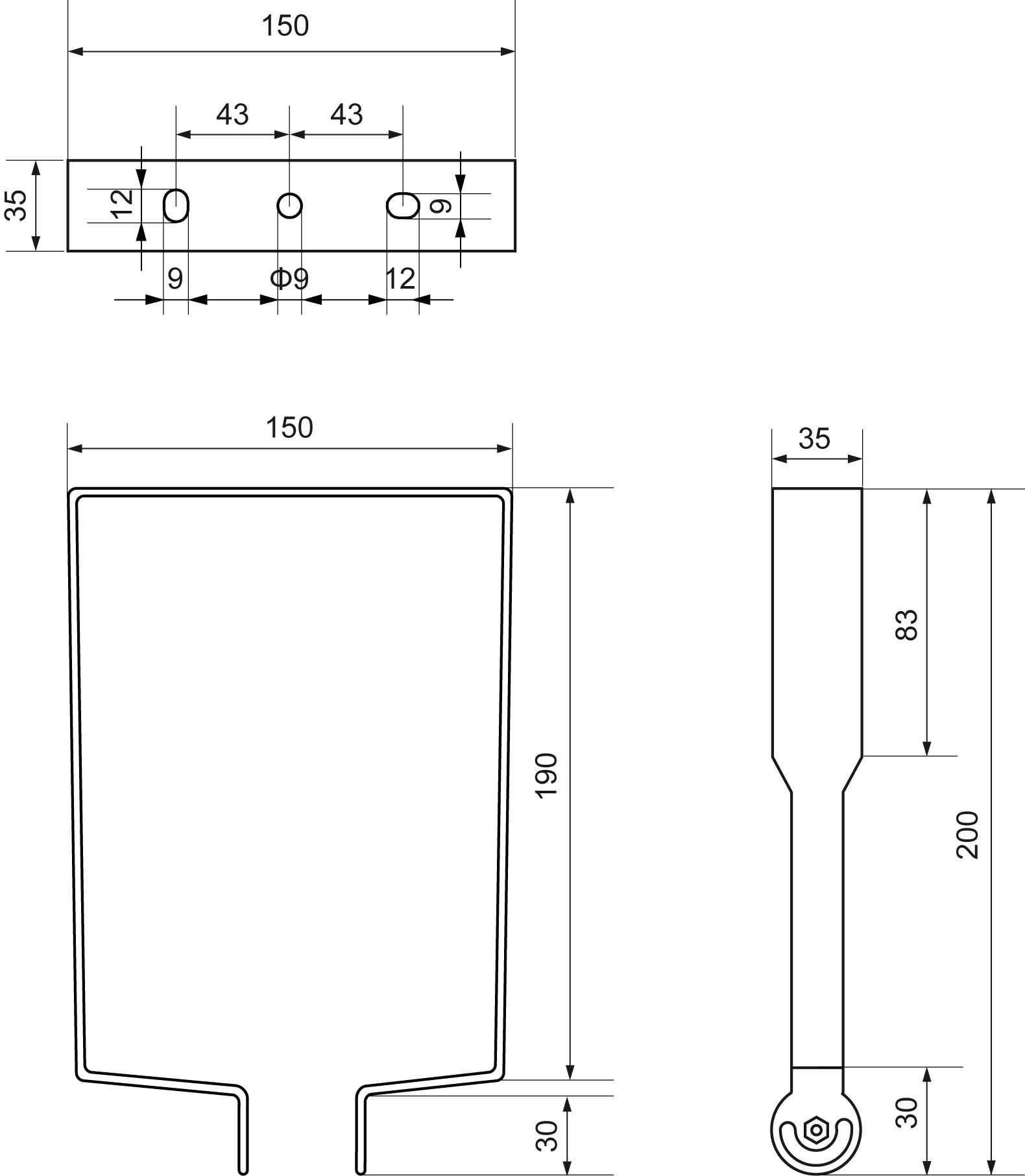

Gantry frame size:

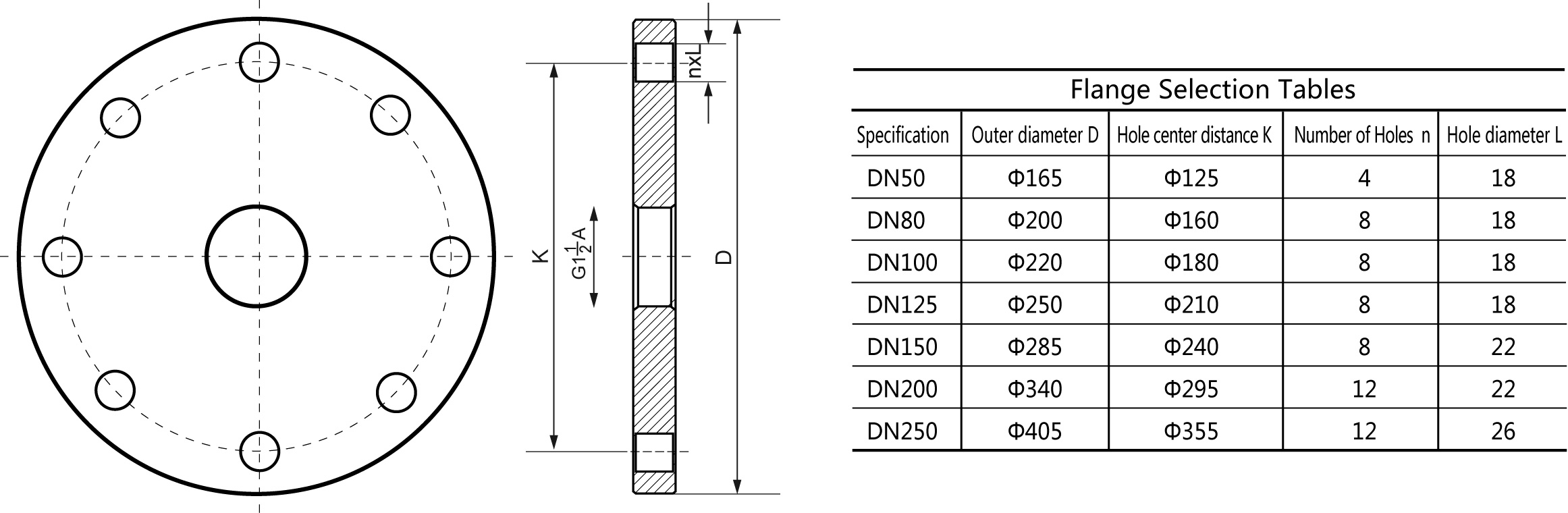

Flange type:

7. Technical Parameters

Process connection/antenna profile | flange / 304 stainless steel Dragon door frame/stainless steel, carbon steel |

Liquid materia | l PTFE |

The outer shell material | Cast aluminum, plastic, stainless steel |

The seal between the shell and the shell cover | Silicone rubber |

Casing window | Polycarbonate |

The ground termina | Stainless steel |

The power supply voltage | |

Four wire system | (6~24) V DC(Modbus-RS485) / 198~242VAC(Double cavity and isolation)/110VAC (Double cavity and isolation) |

Two wire system | DC 24V |

Allowable ripple | - <100Hz Uss<lV - (100~100K) Hz Uss<l0mV |

The cable parameters | |

Cable entrance / plug | 1 M20xl.5 cable entrance |

Terminal | Conductor cross section 1.0mm² |

Output parameters | |

The output signal | Modbus-RS485 / 4~20mA |

Communication protocol | Modbus / HART |

Resolution | 1.6μA |

Fault signal | Constant current output; 20. 5mA;22mA;3.9mA |

The integral time | (0 ~ 36) s, adjustable |

| Blind area | the ends of the antenna |

The maximum distance measuremen | 20 meters |

Microwave frequency | 26GHz |

The measurement interval | about 1 second (depending on the parameter settings) |

Adjust the time | about 1 second (depending on the parameter settings) |

Display resolution | 1 mm |

Working storage and transportation temperature | (-40~80) ℃ |

Process temperature (the temperature of the antenna part) | (-40~80) ℃ |

Pressure | Normal atmospheric pressure |

Seismi | Vibration frequency (10~150) Hz, maximum vibration acceleration l0m/s² |

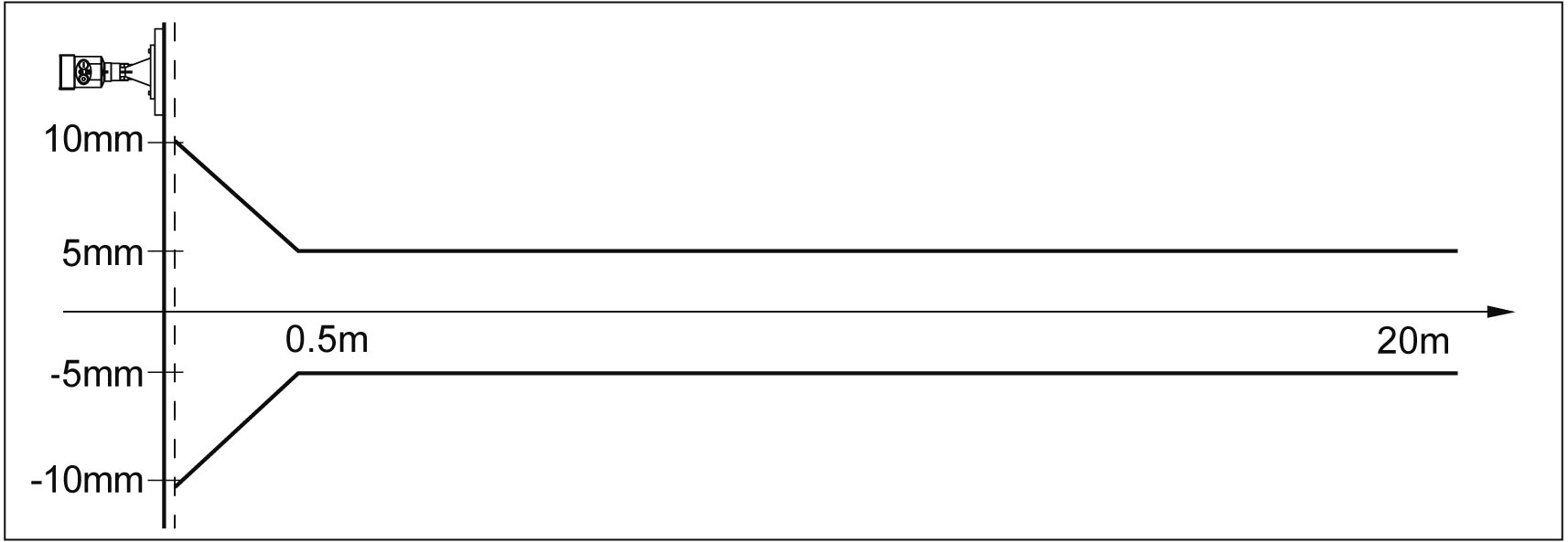

8. Meter Linearity

902F

The launch angle depends on the antenna size

-Φ76mm 12°

Precision See chart

9. Product Model Selection

902F

License |

P Standard (Non-explosion-proof) I Intrinsically safe (Exia ⅡC T6 Ga) D Flameproof (Exd ⅡC T6 Gb) |

Process Connection / Material |

A gantry frame B DN80 flange/ Stainless Steel 304 C DN100 flange/ Stainless Steel 304 D DN125 flange/ Stainless Steel 304 E DN150 flange/ Stainless Steel 304 F DN80 flange/ PP G DN100 flange/ PP H DN80 flange/ PP I DN100 flange/ PP G Special Custom |

Antenna Type / Material |

A 78mm plastic sealed antenna |

Seal Up / Process Temperature |

V Ordinary seal/(-40~80) ℃ |

The Electronic Unit |

V Modbus-RS485 / 6~24V DC four-wire system W (4~20) mA / 24V DC two-wire system X (4~20) mA / 220V AC four-wire system |

Cable Line |

M M 20x1.5 N ½″ NPT |

Field Display/The Programmer |

A With X Without |

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist