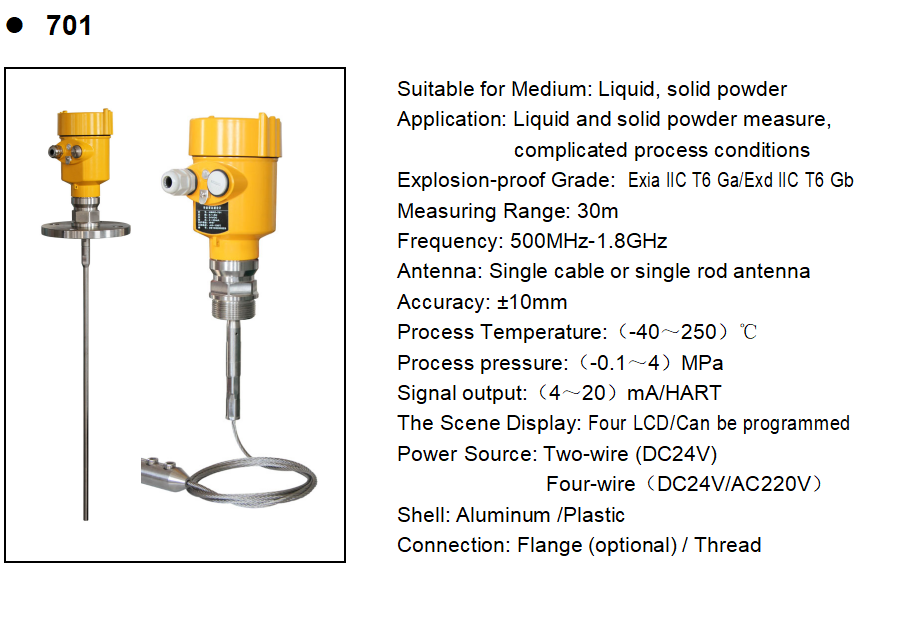

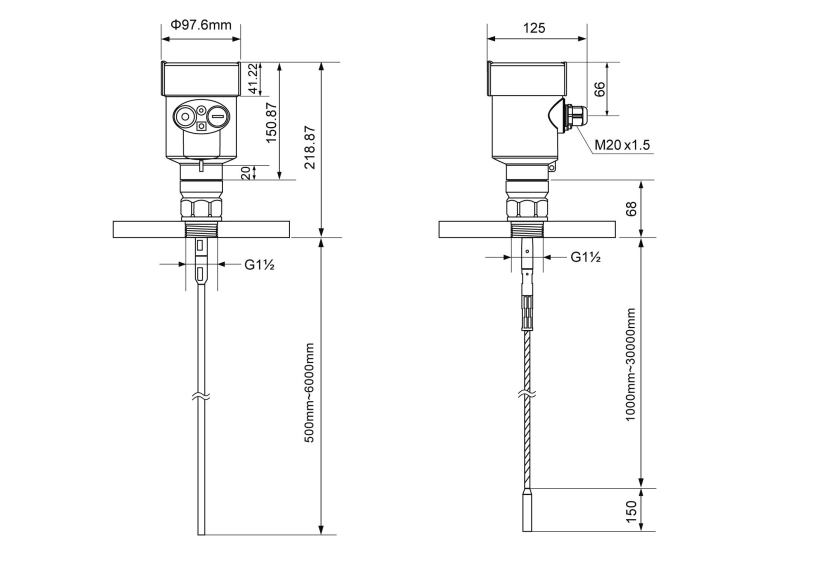

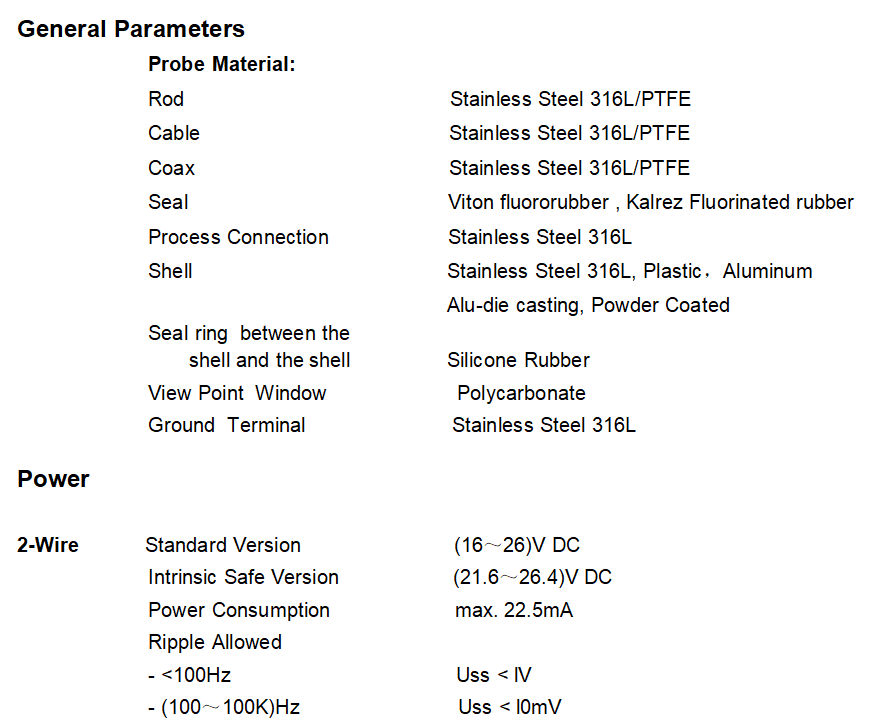

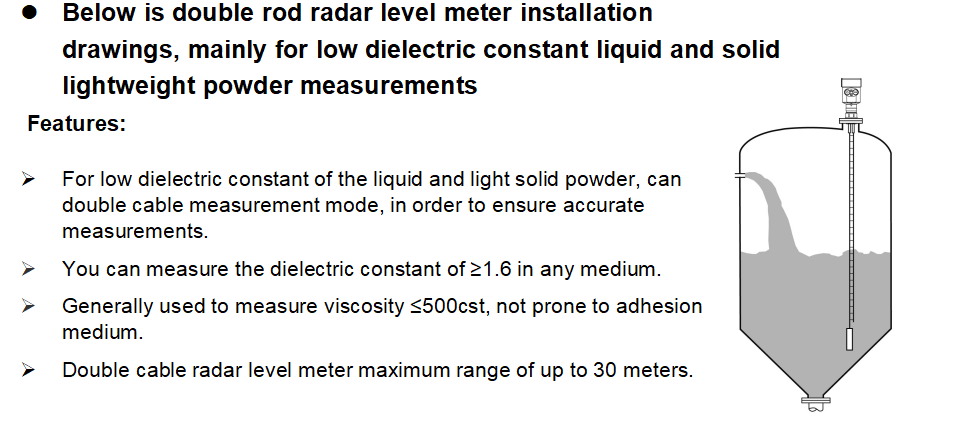

Within chemical plants and various production workshops, storage tanks serve as critical equipment for material storage, buffering, and distribution. These tanks not only centralize the storage of process media but also play a vital role in load regulation, process continuity control, and trade measurement settlement for the entire facility. Consequently, the precise and stable measurement of internal liquid levels in storage tanks remains the core foundation for production operation monitoring, safety risk prevention, and economic management.1. The Importance of Liquid Level DataFrom a production management perspective, liquid level data directly impacts process continuity and unit load control. For instance, in continuous reactors or storage tanks, material feed rates, reflux ratios, and pumping speeds often depend on real-time liquid level readings. Inaccurate or delayed level measurements may result in insufficient material supply, increased process fluctuations, or even abnormal unit loads, posing threats to production safety and product quality.From a safety management perspective, abnormal liquid levels are a key contributing factor to many storage tank incidents. Excessively high levels may cause tank overflows, foam blowouts, or pipeline backflow; excessively low levels may trigger pump dry running, heater dry burning, or abnormal chemical reactions. In high-temperature, high-pressure, flammable, and explosive chemical environments, liquid level anomalies often pose severe safety risks. Therefore, storage tank liquid level measurement serves not only as an operational monitoring tool but also as a critical safety safeguard.From an economic management and trade settlement perspective, the accuracy of storage tank level measurement directly impacts corporate profitability and compliance. In the trading of petroleum products, chemical raw materials, and finished goods, tank levels form the basis for volumetric measurement. Any measurement deviation can lead to financial losses or trade disputes. Particularly in tank farm metering and batch settlement, the traceability and stability of level data are critically important.In summary, selecting a tank level gauge is not merely a matter of “whatever fits will do.” It is a systematic engineering task that requires comprehensive consideration of multiple factors, including process conditions, medium characteristics, safety requirements, and operational and maintenance costs.2. Key Factors for Level Gauge Selection2.1 Medium PropertiesThe density, viscosity, corrosiveness, conductivity, and volatility of the medium inside the storage tank directly influence the choice of level gauge measurement principle. For example:Low-density liquids: Standard float switches or rotary paddle switches may fail to trigger accurately. In such cases, vibrating, radar, or ultrasonic level gauges can be employed.Highly corrosive liquids: Select probes made of corrosion-resistant materials such as PTFE, PVDF, or 316L stainless steel, and incorporate leak-proof designs.High-viscosity or crystallizing media: Mechanical contact-type level switches are prone to buildup; non-contact radar or guided wave radar is more suitable.2.2 Process ConditionsProcess conditions at the storage tank location—including temperature, pressure, agitation status, and foaming—all impact level measurement.High-temperature/high-pressure environments: Select level gauges designed for high-temperature/high-pressure conditions, while also considering factors like probe thermal expansion and insulation for electronic modules.Agitation or circulating flow: Significant level fluctuations may cause frequent actuation of traditional float or rotary paddle switches. Choose level gauges with filtering or delay processing capabilities.Foam or Bubbles: Ultrasonic measurement is susceptible to foam interference. Radar level gauges can identify primary echoes through signal processing algorithms, enabling stable measurement.2.3 Measurement Accuracy and Response RequirementsDifferent applications demand varying levels of liquid level measurement accuracy and response speed. For example:Precision Process Control: Reactor liquid level control requires high-accuracy continuous measurement, such as guided wave radar or hydrostatic level gauges.Overfill Protection or Empty Tank Guarding: Highly reliable switch-type level gauges can be used, such as vibrating fork or rotary paddle switches.2.4 Safety and Protection RatingsIn the chemical industry, explosion-proof design and leak prevention measures are critical. Select intrinsically safe (Ex ia), explosion-proof (Ex d), or enhanced safety (Ex e) level gauges based on tank farm classifications. Additionally, prioritize protection ratings (IP ratings) to ensure long-term reliable operation of electronic components and probes in dusty, vaporous, or rainy environments.2.5 Total Life Cycle CostLevel gauges involve not only procurement costs but also installation, commissioning, routine maintenance, calibration cycles, and replacement frequency. Proper selection reduces operational expenses and minimizes production downtime losses caused by equipment failures.3. Common Types of Tank Level Measurement Instruments and Their Suitable EnvironmentsFloat Level SwitchSuitable for low-temperature, low-pressure, non-viscous liquids. Low cost and easy installation, but unsuitable for high-viscosity, crystallizing, or foaming liquids.Rotary Paddle Level SwitchSuitable for solid-liquid separation or slurry level monitoring. Rugged construction and corrosion-resistant, suitable for medium to low-density media.Vibrating Fork Level SwitchTriggers upon non-contact or light contact with material. High sensitivity enables measurement of low-density materials or foamy particles. Low maintenance costs.Radar Level Transmitter (Non-Contact/Guided Wave)Suitable for high-temperature, high-pressure, foamy, steamy, viscous liquids, or harsh environments. Provides continuous, precise level measurement and integrates with automated control systems.Ultrasonic Level TransmitterCost-effective for standard tank level measurement, though susceptible to interference from steam, foam, and obstructions.Hydrostatic Level TransmitterCalculates liquid level by measuring hydrostatic pressure. Suitable for tanks with simple structures and stable liquid density. Requires careful selection for high-temperature or crystallizing media.4. Level Gauge Selection Practices and Engineering RecommendationsSystematic Evaluation: Conduct a comprehensive analysis considering tank material, liquid properties, process conditions, measurement accuracy requirements, safety ratings, and budget constraints.Redundancy and Safety Design: For critical tanks, implement primary/backup level gauges or dual systems (switch + continuous level) to enhance safety and reliability.Digitalization and Remote Management: Modern level gauges support digital communication protocols (e.g., 4–20 mA, HART, Modbus, wireless signals) to facilitate remote monitoring, data logging, and process optimization.Maintenance and Calibration Strategy: Develop periodic inspection and calibration schedules based on liquid properties, operating environment, and measurement accuracy to ensure long-term stable operation.5. Engineering Value and Management SignificanceProperly selected level gauges not only provide long-term reliable and traceable data support but also reduce maintenance frequency, ensuring production continuity and safe operation. Furthermore, precise level measurement holds significant value in trade settlement, inventory management, and refined operations.Conversely, improper selection may amplify measurement errors, increase failure rates, and even create safety hazards in critical operating conditions. Therefore, level gauge selection transcends mere instrumentation concerns, becoming a crucial indicator of system safety, production stability, and operational capability.6. ConclusionIn modern chemical plants and production workshops, tank level measurement serves as a critical foundation for production management, safety protection, and economic oversight. Level gauge selection must holistically consider medium properties, process conditions, safety requirements, and total lifecycle costs. Through systematic evaluation and scientific selection, it enables controllable production processes, reliable equipment safety, and refined management.In today's era of deepening automation, intelligence, and refined management, level gauge selection transcends mere instrumentation engineering—it fundamentally reflects process safety and operational efficiency. Through rational selection, scientific installation, digital commissioning, and intelligent operation and maintenance, tank level measurement provides robust support for production safety, process optimization, and economic benefits.

Read More>>