PRODUCT OVERVIEW

Belt Sway Switch is a protective switch for detecting the meandering (sway or deviation) of belt conveyors, and sends out an alarm signal and an emergency stop signal.

It’s suited to be used for belt breakage prevention and orefalling prevention due to the belt sway. Widely used in iron and steel, cement and chemical plants, thermal power plants, etc., since it is essential for safety operation of belt conveyors.

The BELT SWAY SWITCH functions in two ways:Detecting any deviation or sway in the conveyor belt and providing an alarm and sending out signal to stop the conveyor.

Use of this switch in material transport system can prevent damage to the conveyor belt and/or drive system and avoid consequential confusion on transport lines in the event of an accident.

The Belt Sway Switch is constructed with high reliability micro switches, lubricate less ball bearings, a touch pulley which is tilted to 750, and other parts ; its functions are designed with a large margin for sure action and long life .The switch has the difference of 20 between ON and OFF, to switch certainly at an action point. Therefore,this switch can prevent belt conveyor troubles by a simple circuit

SPECIFICATIONS

Reset mode | Manual | Number of contacts | 1a1b |

Contact capacity | AC:90-380V, 5A | Switch angle Level 1 | 20° |

Actuating Force | 3.4-5.4N (0.35~0.55kgf) | Switch angle Level 2 | 35° |

Ambient temperature | -20 °C ~ +60 °C | Weatherproof Type. | IP67 |

Color code | Y100M20C70BL50 | Cable connection | 8 ~ 12mm |

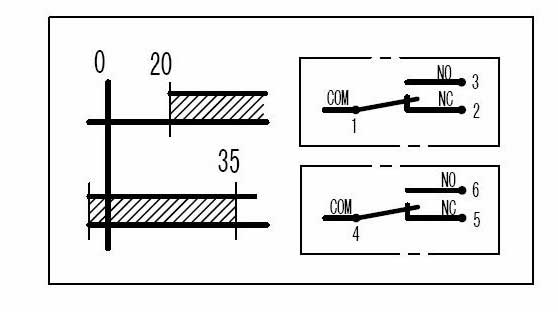

WIRING DIAGRAM

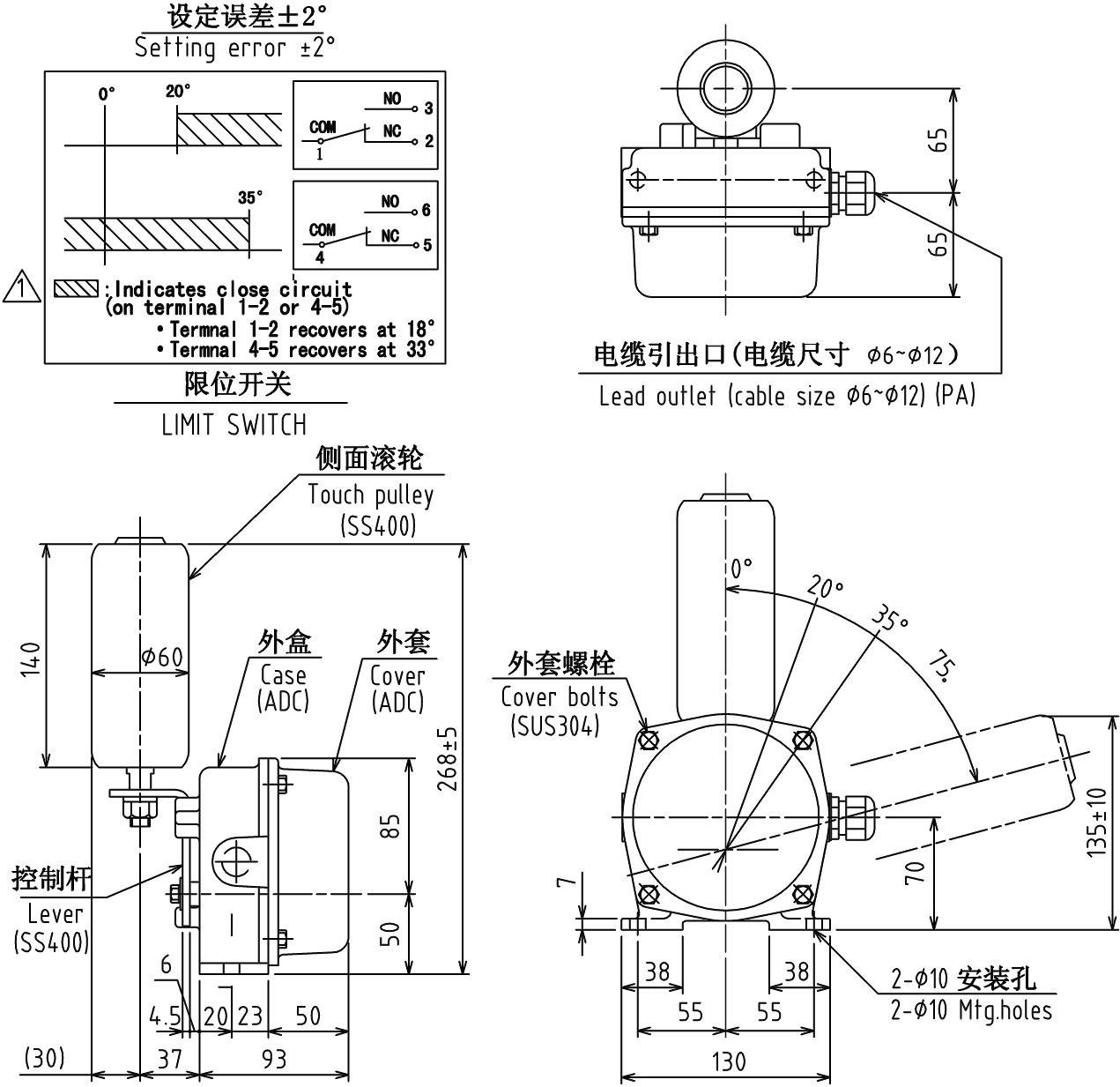

DRAWING

ENVIRONMENTAL CONDITIONS

The Belt Sway Switch should be used in the following environmental conditions; especially made products should be used at the allowable conditions noted in the approved drawing or the final drawing.

l Temperature: -10°C ~ +50°C

Do not use the Belt Sway Switch in the place where there is danger of freezing.

l Humidity less than 80%

l Dust

If much dust adheres to the touch roller and it solidifies the Belt Sway Switch will not move normally. To prevent dust from adhering to the touch roller, it should be cleaned at regular intervals.

Fitting bolts

The fitting bolts should be prepared before installation, and should be fitted into the mounting holes according to their length.

Mounting Base

The mounting base fitted to the belt conveyor should be prepared before installation. When you are deciding the dimensions of the mounting base, refer to Fig.2.

Installation

The dimension from the position of installation to the top of the idler of the belt conveyor should be fixed at 160 millimeters.

Periodic Inspection

(1)Cleaning

Always clean when an excessive amount of dust accumulates on the touch roller.

(2)Wear of Touch Roller

Check wear of the touch roller . When 2 millimeters are worn off the roller, replace as explained in 6.3.

(3)Confirmation of Action

Check to see if the Belt Sway Switch is working normally by testing the touch roller.

Lubrication

The Belt Sway Switch has no need to lubricate.

Replacement of Touch Roller

By loosening the 12 millimeters-sized nut, the touch roller can be taken off easily from the lever.

Secure the nut when the touch roller is replaced, or the Belt Sway Switch may cause trouble if the nut comes loose .

Tightening of Cover

When taking off the cover of Belt Sway Switch for the sake of writing, adjusting and checking, secure the screws of the cover after working, or the Belt Sway Switch may cause trouble due to water and dust entering from between the cover and casing.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist