OVERVIEW

The High level sensor is an overfill prevention switch that may be adjusted to operate over a wide range of levels. The High level sensor is based on float-switch technology and is made of chemical-resistant materials to assure compatibility with most liquids.

The high-temperature rotary resistance level controller is suitable for controlling the material level in various open containers.

The instrument adopts special oil seal design, has double layer dustproof, and has clutch device to protect the motor.

and clutch device to protect the motor, reliable work, easy to use and maintain.

High temperature level sensor is widely used in chemical, food, mining, plastic, ceramic and other industrial

It is widely used in chemical, food, mining, plastic, ceramic and other industrial industries, and is a kind of ideal simple material level control instrument.

WORKING PRINCIPLE

The controller adopts the principle of electromechanical position control and contact measurement of material level. When there is no material in the blade part of the silo

When there is no material in the blade part of the silo, the level is energized, the indicator light is on, and the blade rotates counterclockwise; when there is material in the blade part of the silo

When there is material in the blade part of the bin, the blade rotation is blocked, the control signal is converted, and then the power supply of the motor of the material level is disconnected. When there is material in the blade part of the bin, the blade rotation is blocked, the control signal is switched, and the power supply of the motor of the leveler is disconnected. Start to rotate, the control signal is switched. The output of the material leveler is the switch signal, the user can realize the material level by the switch signal of the material level controller. The user can realize the automatic control of material level by the switch signal of the controller.

TECHNICAL PARAMETERS

Voltage | AC220V/1A:DC24V/0.5A |

Power | 3W |

Temperature | -20 ~ 80 °C |

Blade speed | 1RPM |

Withstanding Voltage | 1500VAC x 1min |

Torque | 10kg-cm |

Installation | Vertical installation |

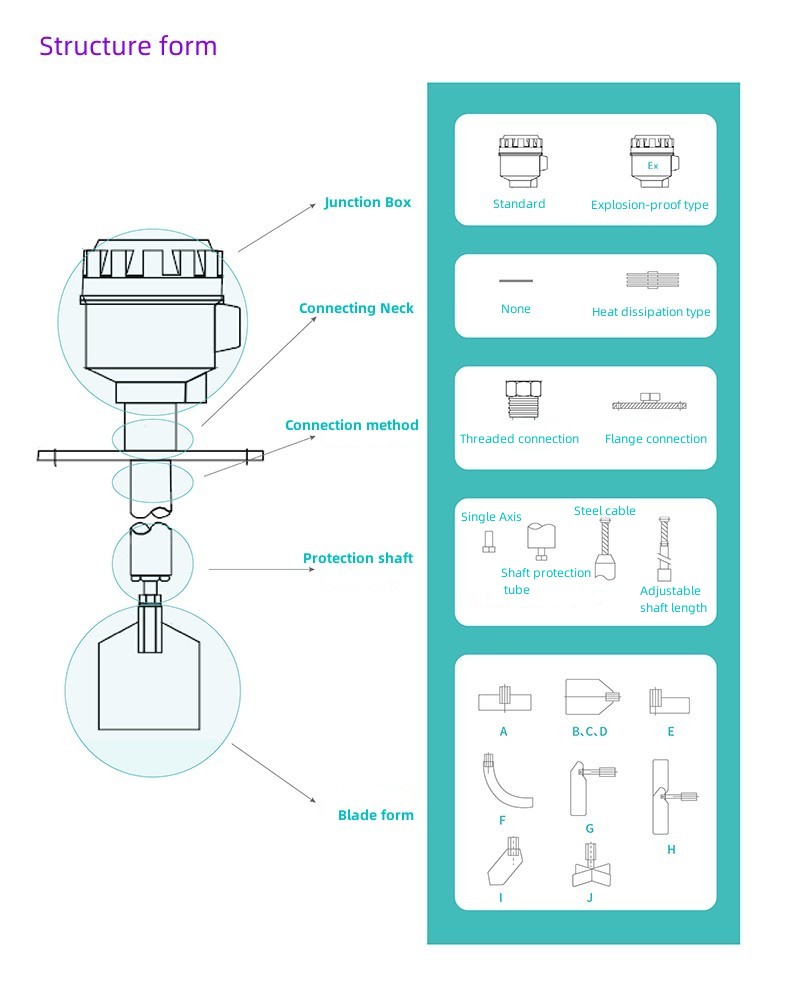

STRUCTURE FORM

SELECTION NOTES

1. Confirm the voltage 24VAC.

110V, 220VOR 240V, 50/60Hz .

2. Confirm the installation method (side or top mounted).

3. Pay attention to the specific gravity of raw materials.

4. Confirm whether the blade size can be inserted into the flange inlet or barrel wall opening.

INSTALLATION SCHEMATIC

Established in 2008, Guangdong KAIDI, it has transformed into a well-known brand. Kaidi's cooperation company has a modern workshop that fully meets GMP standards. It has certification of ISO22716 &ISO9001:2015, equipped with the first set of V M I TRIMIX imported from France in China. Also we have 24 canning and packaging production lines in cleanliness of 100000 grade workshop. The daily output can reach 200000 PCS. We are professional manufacturer of makeup and cosmetics OEM\ODM.We have a development team that has been serving the cosmetics industry for more than 20 years and has established a long-term cooperative R&D laboratory in Japan.Our inspection center is a laboratory established according to the ISO17025 standard. The inspection center has advanced imported testing instruments.We accept small batch orders and can provide proofing. We have multi-order and multi-spec production capacity, and a variety of cooperation options are available.Most of our products are sold from stock, the price of customized products is very competitive in the market, and we can complete the order delivery within 1 week.Joejovi's perfect cosmetics have obtained the global market recognition, and major buyers are welcome to visit and negotiate.

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.