BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Power source: 110VAC Or 220VAC

Power consumption: 3W

Contact capacity: SPDT 220VAC/5A 250VAC/ 220VAC/3A 250VAC

Rotary speed: 1 R.P.M.

Insulation test voltage: AC 1500V in 1 minute

Torque: 0.3~1N﹒M

Specific gravity: 0.5g/cm3 0.3g/cm3

For further information, please contact your local distributor, sales representative or our Service Department.

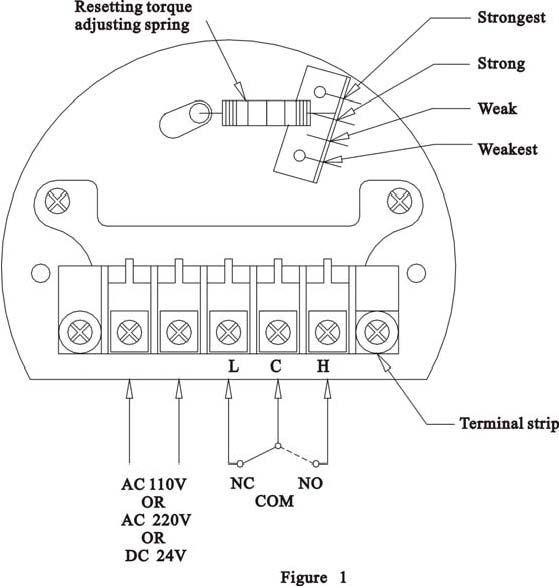

The torque spring is applied to adjust the shaft output torque force, which is set at “weak” position at factory side, it is adjustable as per customer side target measuring material S.G.(special gravity),if the measured material with higher S.G., please try to release it to more stronger spring force position step until you found the proper orientation.

The paddle sensitivity will be interacted by weaker, otherwise, the low S.G. material will release torque spring to the weakest position, which will cause the paddle performance to be more sensitive.

Note: the torque force should not be adjusted during test, avoiding the error check signal.

CAUTION

Make sure the supplying voltage is same as the specifications.

Wrong voltage will damage the sensor.

WARNING

To avoid personal injury, DO NOT removes the housing cover after supplying the power. If you will touch any solder joints and terminals, you may receive an electric shock.

Please check that the shaft and the paddle is bended or is damaged;

Please check the connect between the shaft and the paddle;

Do cleaning the shaft and the paddle timely.

Please side mount the switch by inclined 15°~20°to decrease the material inflowing impact;

The wiring entry face downward, avoid the rain permeate into housing body.

Please make sure whether any bridge block or vibrating motor installed onto the tank wall. Please try to apply our item separate LB1110 RF level switch.

Note: those types can be side installed onto the tank wall only, they are KDSS86, KDSS86F, KDSS11, KDSS86M, KDSS86FT, KDSS86mini, (horizontal mounting)

Both KDSS86G and KDSS86GT are vertical mounting only.

When do installing or maintenance, the warning read as “open the level after the power source is off” should be obey to.

When there is the corrosive gas ambient, the aluminum and the stainless steel material should be avoid be used.

In the material tanks there is liquid or gas in it ,the temperature cannot go beyond the limit which the level switch can operating normally.

The following table is the solutions for the normal problems:

| The problem | The reason | The solution |

| There is not output signal, although the paddle rotates at all times | Because the material special gravity, the paddle dimensions cannot fit the material | Replace the suitable paddle |

| The paddle is distortion or the shaft is bended | The inflowing impact force of the material is too large | The paddle and the shaft should be protected |

| The paddle do not rotate | 1)the power source isn’t on | 1)check the connect of the power wiring |

| 2)the motor is damaged | 2)replace the motor |

Please make sure the Voltage 24 VAC, 110VAC ,220VAC or 240VAC, 50/60Hz.

Please make sure the side or top mounting.

Please make sure the material specific gravity (S.G.) value.

Please make sure the rotary paddle size is available to enter into the flange inlet.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist