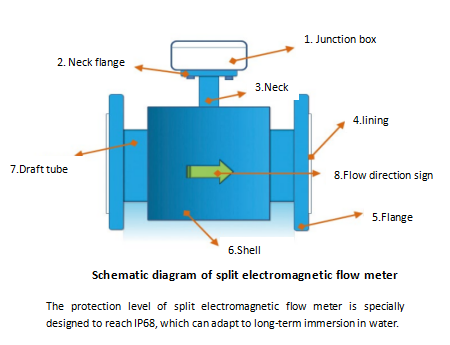

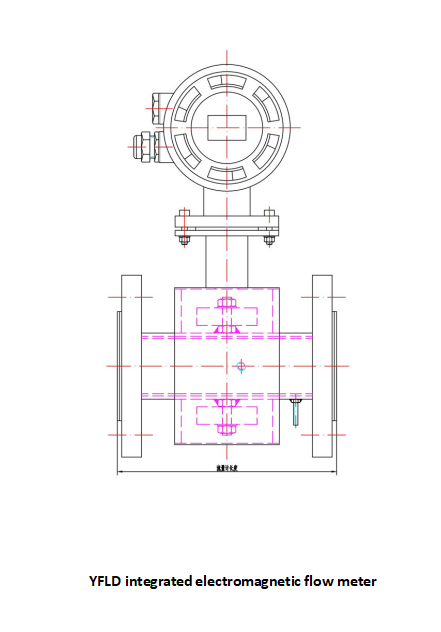

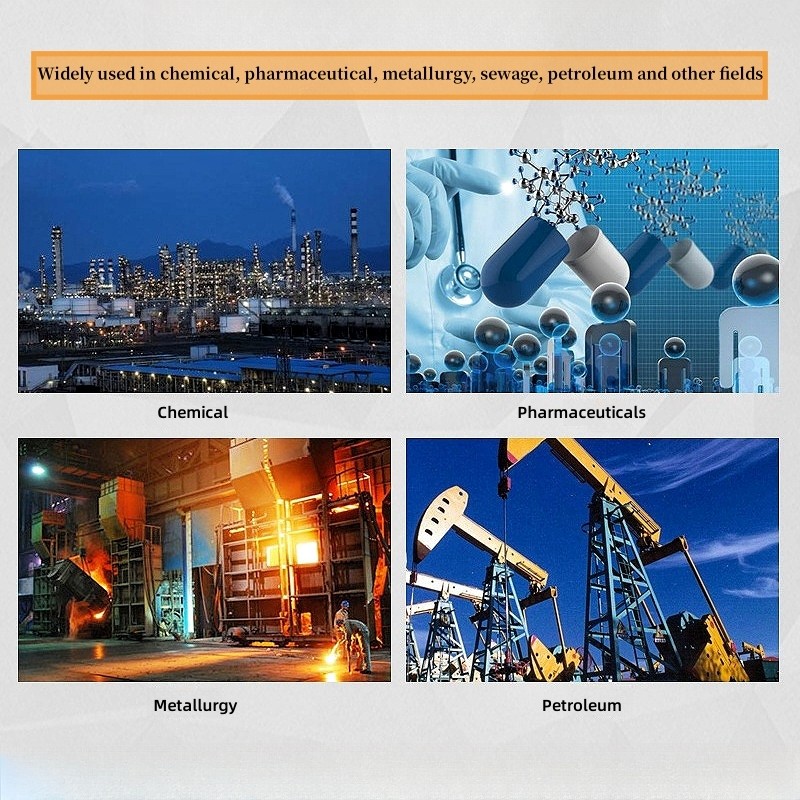

Electromagnetic Flowmeters (Electromagnetic Flowmeters, simply known as EMF) is the 20th century 50 ~ 60 years with the development of electronic technology and the rapid development of a new type of flow measurement instrumentation, electromagnetic flowmeter is the application of the principle of electromagnetic induction, according to the conductive fluid through the applied magnetic field generated by the electromotive force to measure the flow of electrically conductive fluid flow of a kind of instruments, electromagnetic flowmeter The structure of the magnetic circuit system, measuring conduit, electrode, shell, lining and converter and other components, according to the type of installation can be divided into split, insertion type, one-piece, split electromagnetic flowmeter to meet the field display at the same time, but also can output 4 ~ 20mA current signal for recording, regulation and control, insertion type electromagnetic flowmeter is designed for the medium and large aperture measurement of the pipeline, one-piece electromagnetic Flow meter is based on Faraday's law of electromagnetic induction, used to measure the volume flow of electrically conductive fluids, due to the unique characteristics have been widely used in industry for a variety of electrically conductive liquid measurements, mainly used in the chemical industry, papermaking, food, textiles, metallurgy, environmental protection, water supply and drainage and other industries, and computers can be realized with the system control.

➭High measurement accuracy, 0.5 grade, good stability;

➭The measurement is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity;

➭There are no obstructive flow parts in the measuring tube, no pressure loss, and lower requirements for straight pipe sections. It has unique adaptability to slurry measurement;

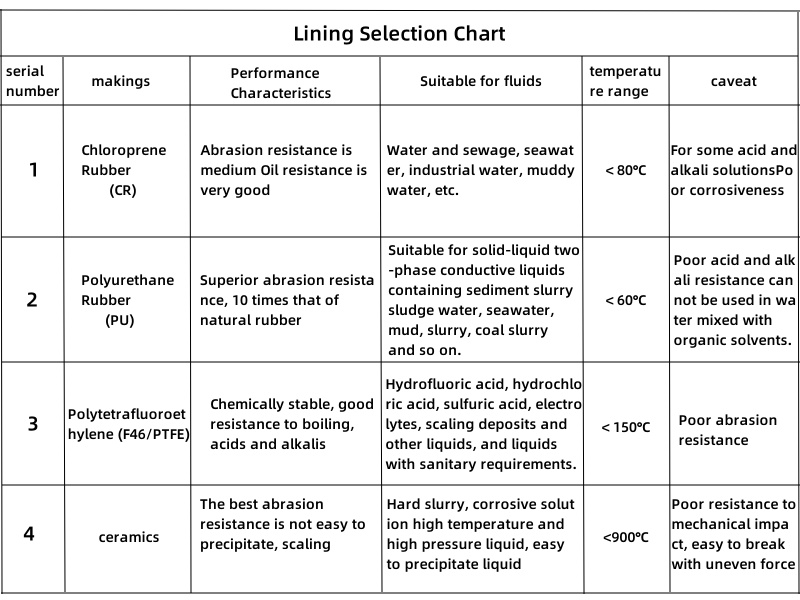

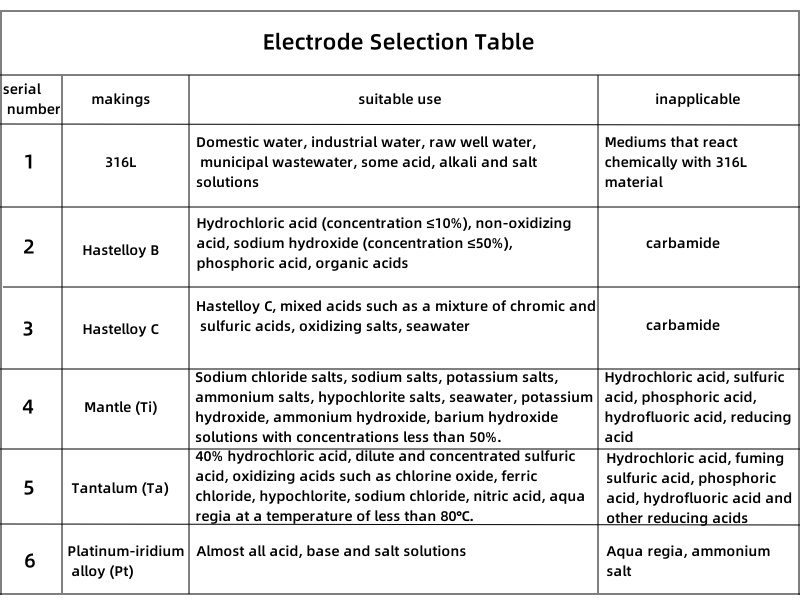

➭Reasonable selection of sensor lining and electrode materials can achieve good corrosion resistance and abrasion resistance;

➭Converter adopts novel excitation method, low power consumption, stable zero point and high accuracy. The flow range can reach 150:1;

➭The converter can be integrated with the sensor or separated;

➭The converter adopts 16-bit high-performance microprocessor, 2x16LCD display, convenient parameter setting and reliable programming;

➭The flowmeter is a two-way measurement system with three totalizers: forward total, reverse total and difference total; it can display positive and negative flow, and has multiple outputs: current, pulse, digital communication, HART;

➭The converter adopts surface mount technology (SMT), with self-check and self-diagnosis functions;

➭The measurement accuracy is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity. The sensor induced voltage signal has a linear relationship with the average flow rate, so the measurement accuracy is high;

➭There are no obstructions in the measuring pipeline, so there is no additional pressure loss; there are no moving parts in the measuring pipeline, so the sensor has an extremely long life;

➭Because the induced voltage signal is formed in the entire space filled with magnetic field and is the average value of the pipe section, the straight pipe section required by the sensor is shorter, and the length is 5 times the pipe diameter;

➭The converter adopts the latest and most advanced single-chip microcomputer (MCU) and surface mount technology (SMT) in the world, with reliable performance, high precision, low power consumption, stable zero point and convenient parameter setting. Click on the Chinese display LCD to display cumulative flow, instantaneous flow, flow rate, flow percentage, etc.;

➭ Two-way measurement system, which can measure forward flow and reverse flow. Special production technology and high-quality materials are used to ensure the performance of the product and remain stable for a long time.

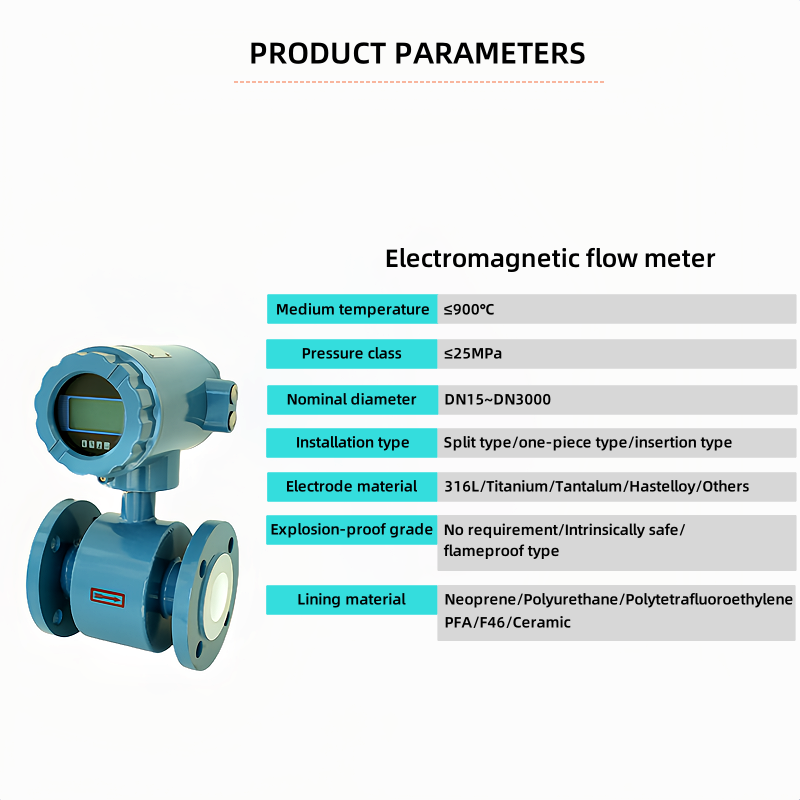

| KD-YFLD | Performance parameter |

| Accuracy Grade | 0.5 level |

| Repeatability | 0.15% 0.25% |

| Conductivity | >20us/cm |

| Measuring diameter | DN15 ~ DN3000 |

| Flow rate range | 0.1 ~ 15m/s; velocity resolution: 0.5mm/s |

| Medium temperature | Rubber lining≦80℃; F4 lining≦150℃ |

| Nominal pressure | 1.0MPa 1.6MPa 2.5MPa 4.0MPa Maximum pressure 25MPa |

| Shell material | 20# carbon steel 304 stainless steel 316L other materials (customizable) |

| Lining material | Neoprene; fluoroplastics (F4, F46, PFA) polyurethane, alumina ceramics, etc. |

| Electrode material | 316L Hastelloy B/C, Tantalum, Titanium, Tungsten Carbide, Platinum-iridium alloy, etc. |

| Power supply | 85 ~ 250VAC 45 ~ 63Hz; 20VDC ~ 36VDC |

| Display interface | Instantaneous flow rate Instantaneous flow rate Positive total amount Negative total amount Net cumulative total |

| Accessibility | Flow accumulation unit can be selected, small signal cutoff, self-contained flow correction function |

| Smart alarm | Fluid empty pipe alarm Excitation current detection alarm Battery capacity detection alarm |

| Additional features | Quantitative alarm Upper and lower limit alarm Empty pipe detection alarm |

| Output signal | Analog current signal Digital pulse signal Digital frequency signal |

| Protocol | Can bring RS485/232 communication HART MODBUS GPRS (optional) |

| Ambient temperature | -30 ~ +60℃ |

| Relative humidity | 5% ~ 95% |

| Protection level | IP67 IP68 (optional) |

| Explosion-proof grade | Intrinsically safe type Exia IICT6 Flameproof type Exd IICT6 |

| Dissipated power | <20W (Connect the sensor) |

KAIDI Sensor,which is a professional level transmiter manufacturer with 20 years of experiences, is dedicated inproviding complete customized solutions for a wide range of industrial automation process applications --inmaterial level, liquid flow, pressure and temperature. We are constantly developing and innovating, our core vision“to provide solutions that exceed customers' expectations.

In 2012, the company successfully expanded its operations both locally and interationally, achieving globalsuccess and recognition for quality fork type level switch, rotary level switch, magnetic level gauges products andservices.

With emphasis placed on customer satisfaction, innovation, product development and overall businesstransformation, the company continued to innovate and expand with each passing year. As a level indicatormanufacturer, KAIDI Sensor has successfully achieved global recognition, obtaining the leading position as Asia'stop process automation sensor and level gauge manufacturers. These were implemented successfully, and KaidiSensors products,such as rotary level sensor and Level Indicator, can be used in many different industries suchas food & beverage, water, energy, pharmaceutical etc. In the past 5 years, the company has undergonetremendous growth and development - flourishing internationally and providing customers worldwide with thebest customized solutions for process automation

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.