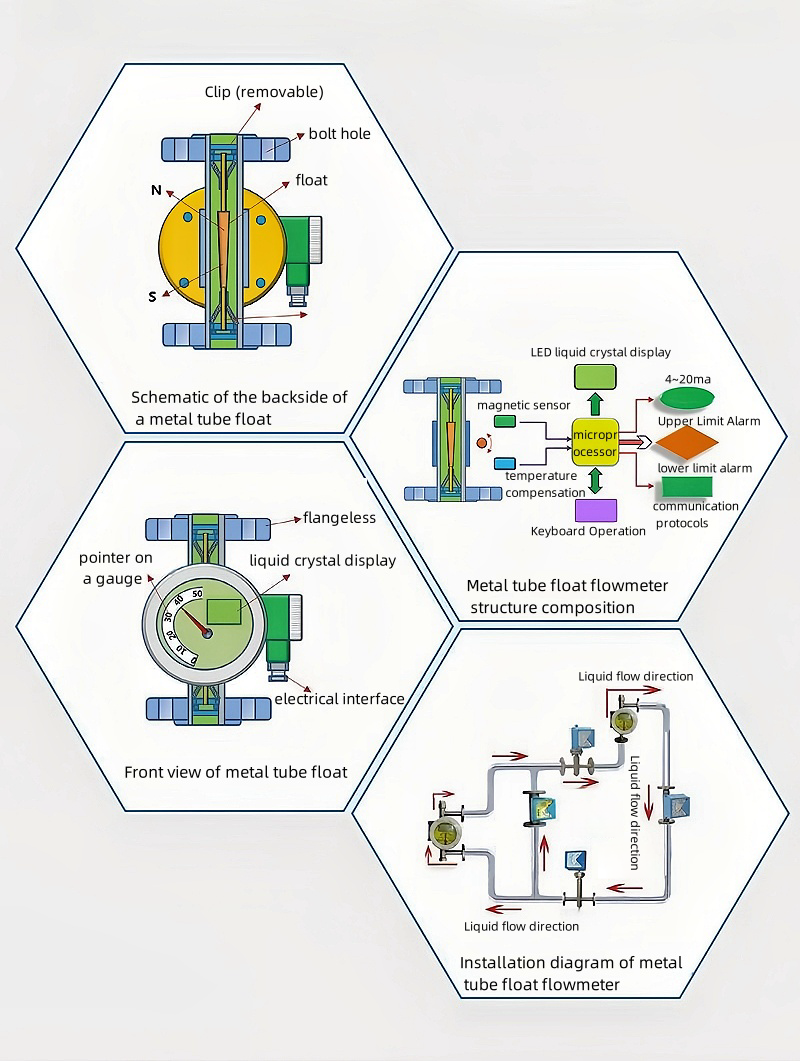

KD-YFFZ metal tube float flowmeter flow detection element is expanded from the bottom up by a vertical conical tube and a vertical cone along the axis of the vertebral tube moving up and down the float is composed of the measured fluid from the bottom up through the vertebral tube and the float formed by the ring gap, the float on the lower end of the differential pressure formed by the float upward force, when the rising force of the float is greater than the float immersed in the fluid in the weight of the float, the float will rise, and then increase the area of the gap, the fluid flow rate at the gap immediately decreased, the differential pressure acting on the float is reduced until the rising force is equal to the gravity of the float immersed in the fluid, the float will be stable, the float will be stable. Ring gap in the fluid flow rate immediately decreased, the float on the lower end of the differential pressure is reduced, the rising force acting on the float is also reduced until the rising force is equal to the float immersed in the fluid gravity, the float will be stabilized at a certain height, the float in the height of the spinal tube and through the flow rate has a corresponding relationship. Rotor flowmeter is generally divided into glass and metal rotor flowmeter, metal rotor flowmeter is the most commonly used in industry, for small diameter corrosive media usually made of glass, due to the fragility of the glass material itself, the key control point is also useful for all titanium and other precious metals for the material of the rotor flowmeter.

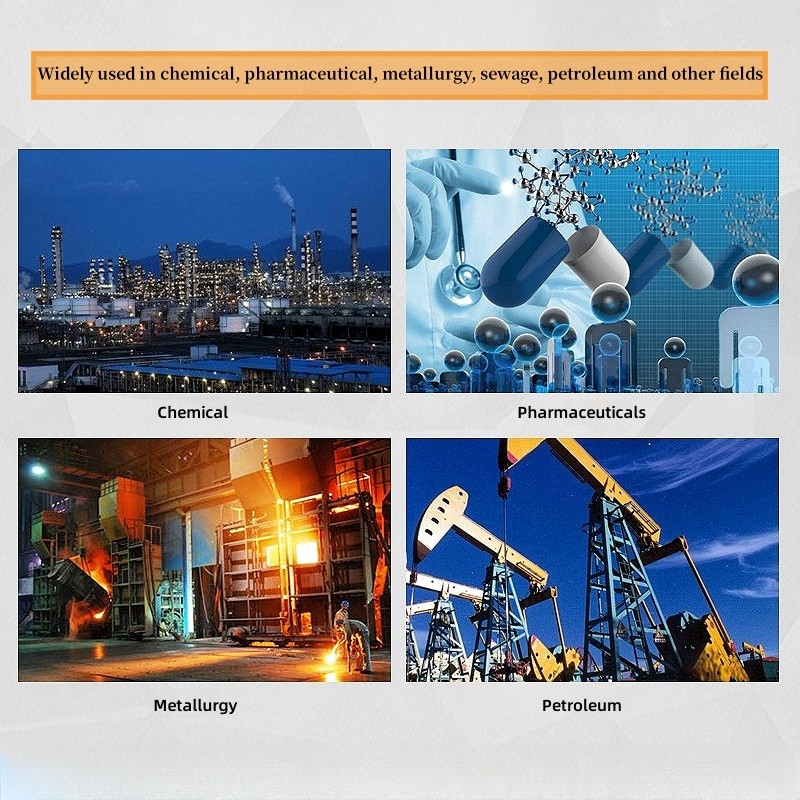

Metal rotor flowmeter is based on the float position measurement of a variable area flow meter, using an all-metal structure, Modular conceptual design, its pressure loss is small, the range ratio is large (10:1), easy to install and maintain, can be widely used in complex, harsh environments and a variety of media conditions of flow measurement and process control. Over the years, the rotor flowmeter's various excellent performance and reliability, as well as a better price-performance ratio widely favored by the petrochemical, iron and steel, electric power, metallurgy, light industry and other industries.

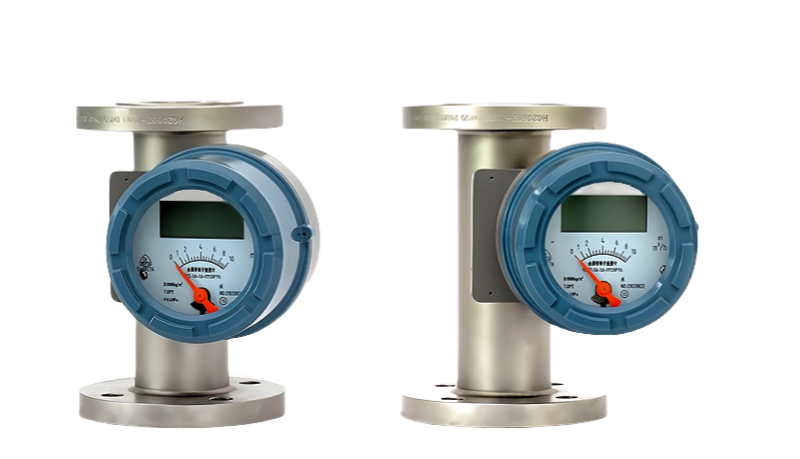

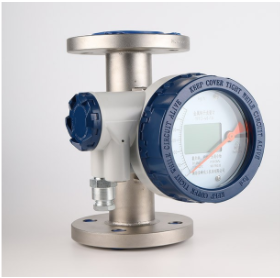

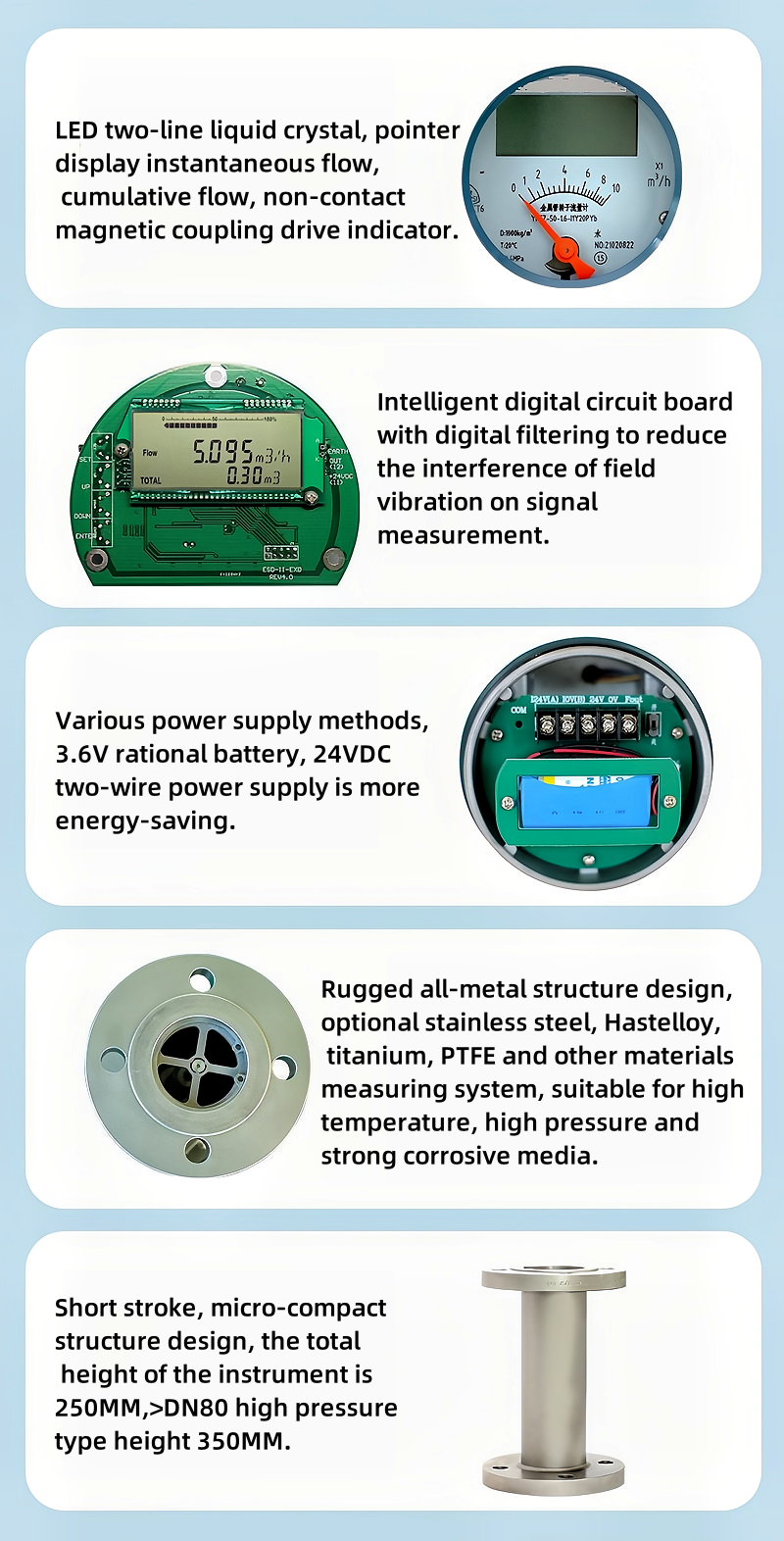

❐Rugged all-metal structure design;

❐ Non-contact magnetic coupling transmission indicator;

❐The measurement system of stainless steel, Hastelloy, titanium and PTFE materials can be selected, which can be suitable for high temperature, high pressure and strong corrosive media;

❐ Low pressure loss design;

❐Short stroke, miniature structure design, total instrument height 250mm;

❐The magnetic coupling structure design ensures more stable signal data transmission;

❐ It can be equipped with thermal insulation or heating jacket structure;

❐The installation method can be divided into vertical and horizontal installation, which can be adapted to various installation occasions;

❐ It is suitable for flow measurement of medium with small diameter and low velocity;

❐The measurement is stable, the work is reliable, the maintenance is small, and the service life is long;

❐ The requirements for straight pipe sections are not high, the first 5DN and the rear 250mm are enough;

❐ Wider flow rate range ratio: 10:1;

❐ Two-line liquid crystal display, on-site instantaneous and cumulative flow display can be selected, with backlight;

❐ It can be used for the measurement of flammable and explosive hazardous environment;

❐ The power supply can choose 24V or lithium battery self-powered type;

❐Multi-parameter intelligent calibration function;

❐ With data recovery, data backup and power failure protection functions;

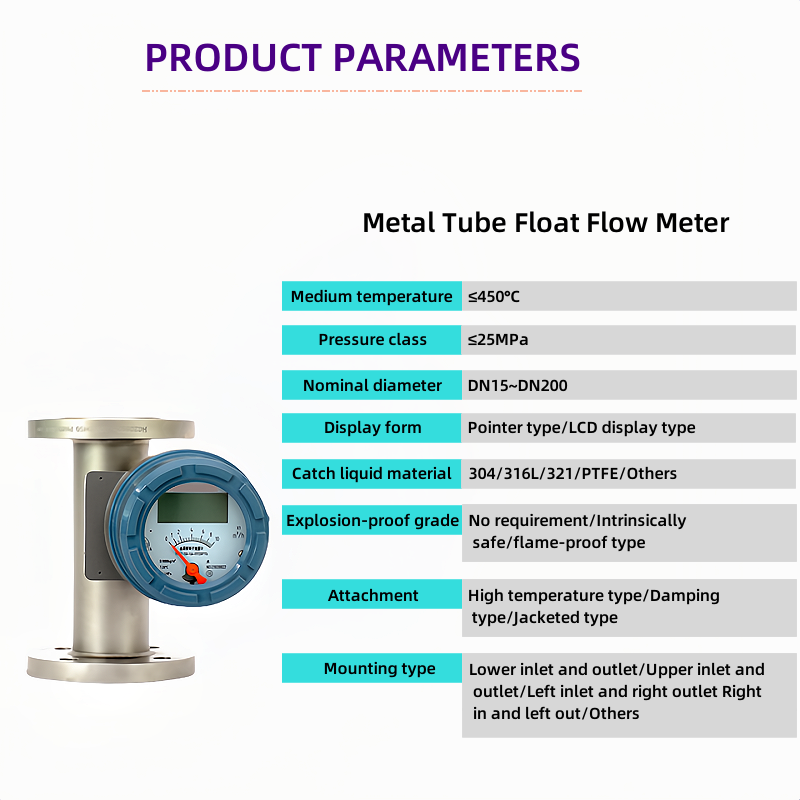

| Flow range | Water (20℃): 1-200000L/h Air (20℃, 0.1013MPa): 0.03-4000m³/h;; |

| Range ratio | Standard type: 10:1; Special type: 20:1; |

| Accuracy | Standard type: Class 1.5; Special type: Class 1.0 |

| Pressure Level | Standard type: DN15-DN50 4.0MPa; DN80-DN200 1.6MPa Special type: DN15-DN50 2 5MPa; DN80-DN200 1 6MPa;; |

| Pressure loss | 7KPa-70KPa |

| Medium temperature | Standard type: -40℃ -100℃; Special type: 100℃ -450℃; |

| Medium viscosity | DN15:η<5mPa.s(F15.1-F15.3) η<30mPa.s(F15.4-F15.8) DN25:η<30mPa.s ; DN50-DN150:η<30mPa.s ; |

| Ambient temperature | Remote transmission type: 40℃~85℃ (the liquid crystal will not be damaged) The liquid crystal works normally at -30℃~80℃ Local pointer type: -40℃~ +100℃;; |

| Connection Type | Standard type: standard flange; special type: any flange standard or thread specified by the customer |

| Electrical Interface | Flameproof type is 1/2NPT internal thread, others are M20*1.5 internal thread; |

| Power supply | Standard type: 24VDC two-wire system 4-20mA (12VDC-32VDC) Alarm type: 24VDC three-wire system 4-20mA (18VDC-28VDC); Battery powered on-site display type: 3.6V lithium battery powered. ≧ 2 years of use; |

| Alarm Output | Upper or lower limit instantaneous flow alarm; switch alarm; relay output; |

| Pulse output | Cumulative pulse output, the minimum interval is 50 virtual seconds; |

| Communication output | RS485、RS232、HART; |

| LCD | Instantaneous flow rate display value range: 0-50000 (decimal point is possible); |

| Protection level | IP65 |

| Explosion-proof grade | Intrinsically safe Exia IICT3~T6 Flameproof Ex d IICT4~T6 |

| Height of instrument | The vertical height of DN15-DN200 standard type is 250mm, the height of >DN80 high pressure type is 350mm |

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.