F E M type intelligent electromagnetic flow meter is composed of two parts: sensor and converter. It works based on Faraday's law of electromagnetic induction. It is used to measure the volume flow of conductive liquids with a conductivity greater than 5μS/cm. It is an induction meter for measuring the volume flow of conductive media. In addition to measuring the volume flow of general conductive liquids, it can also be used to measure the volume flow of strong corrosive liquids such as strong acids and alkalis and uniform liquid-solid two-phase suspended liquids such as mud, mineral pulp, and paper pulp. It is widely used in the flow measurement of petroleum, chemical industry, metallurgy, textile, paper making, environmental protection, food and other industrial departments and municipal management, water conservancy construction, river dredging and other fields.

.jpg)

▲ The measurement is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity.

▲ There are no flow blocking parts in the measuring pipe, no pressure loss, and lower requirements for straight pipe sections. It has unique adaptability to slurry measurement.

▲Reasonable selection of electrode and lining materials, that is, it has good corrosion resistance and abrasion resistance.

▲ Fully digital processing, strong anti-interference ability, reliable measurement, high precision, flow measurement range up to 150:1

▲Ultra-low EMI switching power supply, suitable for a wide range of power supply voltage, and good anti-EMI performance.

▲ Using SMD device surface mount (SMT) technology, the circuit has high reliability.

▲There are no movable parts in the pipeline, no flow blocking parts, and almost no additional pressure loss during the measurement.

▲The measuring range can be modified online according to the actual needs of users at the scene.

▲The measurement result has nothing to do with the flow rate distribution, fluid pressure, temperature, density, viscosity and other physical parameters.

▲High-definition backlit LCD display, full Chinese menu operation, easy to use, simple to operate, easy to learn and understand.

▲ With RS485, RS232, Hart and Modbus Profibus-DP and other digital communication signal output (optional).

▲ With self-inspection and self-diagnosis functions.

▲ Hourly total recording function, recording the total flow in hours, suitable for time-sharing measurement system (optional)

▲ There are three internal totalizers that can respectively display the forward cumulative amount, the reverse cumulative amount and the difference cumulative amount, and the internal power-down clock can record 16 power-off times. (Optional)

▲Infrared handheld manipulator, 115KHZ communication rate, long-distance non-contact operation of all functions of the converter (optional)

According to the principle of Faraday electromagnetic induction, a pair of detection electrodes are installed on the tube wall perpendicular to the axis of the measuring tube and the magnetic line of force. When the conductive liquid moves along the axis of the measuring tube, the conductive liquid cuts the magnetic line of force to generate an induced electric potential. This induced electric potential consists of two The detection electrode detects, the value is proportional to the flow rate, and its value is: E=B•V•D•K converter has 4-20mA output, alarm output and frequency output, and is equipped with RS-485 and other communication interfaces, and Support HART and MODBUS protocol.

| Parameter | Selection table | |||

| Executive standard | Electromagnetic flow meter (JB/T9248—1999) | FEM electromagnetic flow meter | ||

Diameter (mm) (customizable) | Pipeline PTFE lining: DN10—DN600 | Pipe diameter | 10-2000mm | |

| Pipeline rubber lining: DN40—DN2000 | Instrument type | S | All-in-one | |

| L | Split type | |||

| Flow direction | Positive, negative, net flow | Electrode material | M | 316L stainless steel |

| T | Titanium (Ti) | |||

| D | Tantalum (Ta) | |||

| Hb | Hastelloy-B | |||

| Hc | Hastelloy-C | |||

| P | Platinum (Pt) | |||

| W | Tungsten Carbide (WC) | |||

| Turndown ratio | 150:1 | Output | 0 | no output |

| 1 | Pulse equivalent | |||

| 2 | 4-20mA | |||

| Repeatability error | ±0.1% of measured value | Lining material | C | Neoprene (CR) |

| U | Polyurethane rubber (PU) | |||

| F | Polytetrafluoroethylene (F4/PTFE) | |||

| E | Teflon (F46/FEP) | |||

| P | Tetrafluoroethylene perfluoroalkoxy vinyl ether copolymer (PFA) | |||

| Accuracy class | 0.5 level; 1.0 level | powered | 0 | 220VAC |

| 1 | 24VDC | |||

| Medium temperature | High temperature rubber lining: -20~+90°C | Protocol | 0 | No communication |

| 1 | RS485 | |||

| 2 | RS232 | |||

| 3 | Modbus | |||

| 4 | Hart | |||

| PTFE lining: -30~+120°C | Ground ring | 0 | Without grounding ring | |

| 1 | With grounding ring | |||

| 2 | With ground electrode | |||

| High temperature type PTFE lining: -20~+160°C | Withstand voltage rating | P1 | 1.6MPa | |

| P2 | 1.0MPa | |||

| P3 | 0.6MPa | |||

| P-(n) | Negotiate order | |||

| Conventional rubber lining: -20~+60°C | Explosion proof | N | No explosion-proof | |

| E | Explosion-proof Exd[ia]ia II CT5 | |||

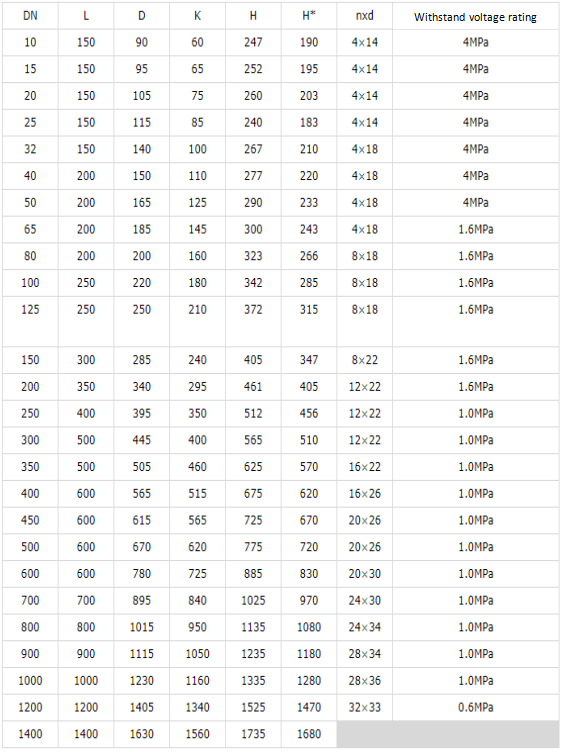

Work pressure (High pressure can be customized) | DN10~DN50≤4MPa | Range | n | Unit: m3/h |

| DN65~DN200≤1.6MPa | Example: F M-100SM2F141P1N-150 | |||

| DN250~DNl000≤1MPa | ||||

| DNl200~DN2000≤0.6MPa | ||||

| Flow rate range | 0.1~15m/s | |||

| Conductivity range | Measured fluid conductivity ≥5μS/cm | |||

| Signal output | 4~20mA (load resistance 0~750Ω), pulse/frequency, Control level | |||

| Communication output | RS485, MODBUS protocol, HART protocol, Profibus—DP protocol | |||

| Power supply | 20VAC, tolerance 15% or 24VDC, ripple ≤5% | |||

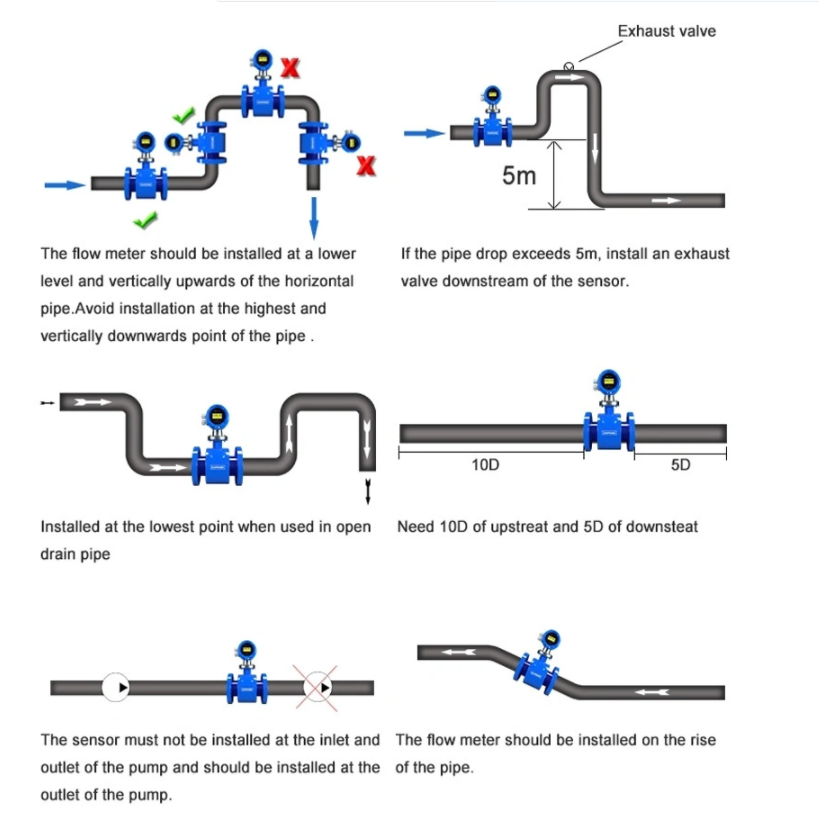

| Length of straight pipe | Upstream≥5DN, downstream≥2DN | |||

| Connection method | Flange connection is adopted between the flow meter and the piping, The flange meets the national standard: GB/T9113.1—2000 | |||

| Explosion-proof grade | Ex dibIIBT4Gb | |||

| Protection level | IP65, up to IP68 for special order | |||

| Ambient temperature | -25~60°C | |||

| Relative temperature | 5%~95% | |||

| Total power consumption | Less than 20W | |||

| Lining material | Name | Symbol | Performance | Maximum working temperature | Applicable liquid | Applicable caliber |

| Rubber | Neoprene | CR | Medium abrasion resistance, resistant to general low concentration Corrosion of acid, alkali and salt | <60°C | Tap water, industrial water,seawater | DN50~2000 |

| Polyurethane rubber | PU | Excellent wear resistance, acid and alkali resistance Poor | <60°C | Pulp, mineral pulp and other slurries | DN50~2000 | |

| Fluoroplastic | PTFE | F4(PTEP) | Chemical properties are very stable, resistant to boiling salt Corrosion of acid, sulfuric acid, aqua regia, concentrated alkali | <160°C | Corrosive acid-base salt liquid | DN25~1600 |

| FEP | F46(FEP) | The chemical performance is equivalent to F4 compressive strength, and the tensile strength is better than F4 | <120°C | Corrosive acid-base salt liquid | DNl0~200 | |

| Copolymer of tetrafluoroethylene and perfluoroalkyl vinyl ether | PFA | The chemical performance is equivalent to F46 Tensile strength is better than F46 | <180°C | Corrosive acid-base salt liquid | DNl0~300 |

| Material | Corrosion resistance |

| 316L | Application: domestic water, industrial water, raw water, well water, urban sewage, weakly corrosive acid, alkali, salt solution |

| Ha B | Application: non-oxidizing acids such as hydrochloric acid (concentration less than 10%), sodium hydroxide (concentration less than 50%), sodium hydroxide alkali solutions of all concentrations, phosphoric acid, organic acids |

| Not applicable: Nitric acid | |

| Ha C | Application: mixed acid and mixed solution of chromic acid and sulfuric acid, oxidizing salts such as Fe+++, Cu++, sea water, phosphoric acid, organic acid |

| Not suitable for: hydrochloric acid | |

| Titanium (Ti) | Application: salt, such as (1) chloride (chloride/magnesium/aluminum/calcium/ammonium/iron, etc.) (2) sodium salt, potassium salt, ammonium salt, hypoaluminate, seawater with a concentration of less than 50% hydroxide Potassium, ammonium hydroxide, barium hydroxide alkali solution |

| Not applicable: Hydrochloric acid, sulfuric acid, phosphoric acid, hydrofluoric acid and other reducing acids | |

| Tantalum (Ta) | Application: Hydrochloric acid (concentration less than 40%), dilute sulfuric acid and concentrated sulfuric acid (excluding fuming sulfuric acid), chlorine dioxide, ferric chloride, hypochlorous acid, sodium cyanide, acetic acid, etc., nitric acid (including fuming nitric acid) Equal oxidizing acid, aqua regia with temperature lower than 80°C |

| Not applicable: alkali, hydrofluoric acid | |

| Platinum (Pt) | Application: Almost all acid, alkali and salt solutions (including fuming sulfuric acid and fuming nitric acid) |

| Not applicable: aqua regia, ammonium salt | |

| Tungsten carbide | Application: Pulp, sewage, anti-interference of solid particles |

| Not applicable: inorganic acid, organic acid, chloride |

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.