Electromagnetic Flow Meter

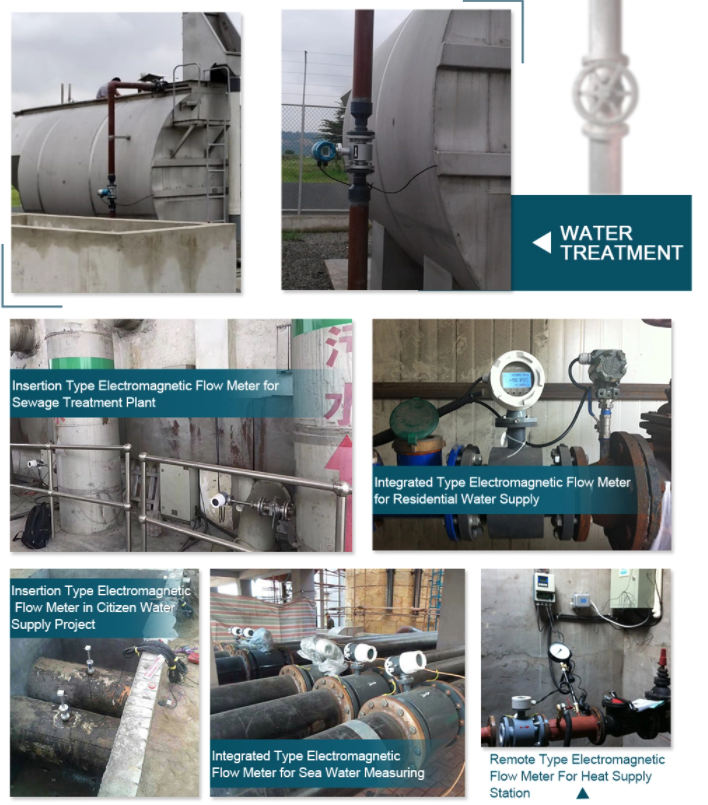

Electromagnetic flow meter (EMF for short) is a new type of flow measuring instrument that developed rapidly with the development of electronic technology in the 1950s and 1960s. Electromagnetic flow meter is an instrument that uses the principle of electromagnetic induction to measure the flow of conductive fluid based on the electromotive force induced when the conductive current passes through the externally clamped magnetic field. There are no obstructions and moving parts in the measuring tube, and the pressure loss is small, so it will not cause additional energy loss or blockage, and the energy-saving effect is significant. It is especially suitable for liquid-solid two-phase flow media, such as sewage, mud, mineral pulp, paper pulp, etc.

▲Unaffected by changes in fluid density, viscosity, temperature, pressure and conductivity, the linear measurement principle enables high-precision measurement;

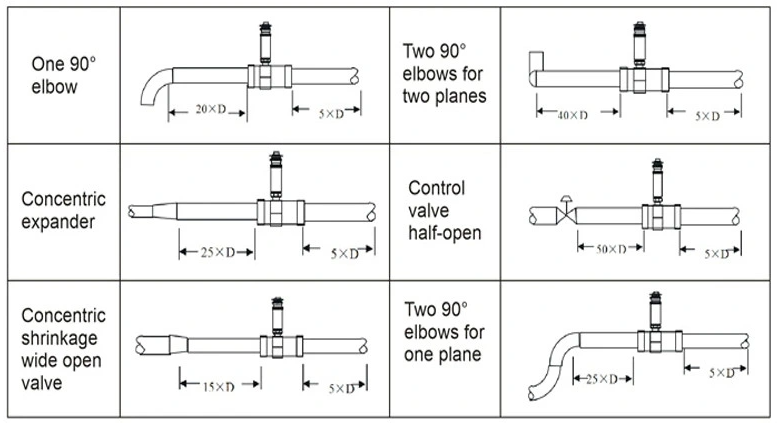

▲The installation requirements are low, the front straight pipe section only requires 5D, and the rear straight pipe section is 2D (D is the inner diameter of the selected instrument)

▲The nominal diameter DN3-DN3000 covers a wide range, and there are many choices of linings and electrodes, which can meet the requirements of measuring a variety of conductive currents.

▲With MODBUS-RS485, HART, GPRS and PROFIBUS communication signal output (optional)

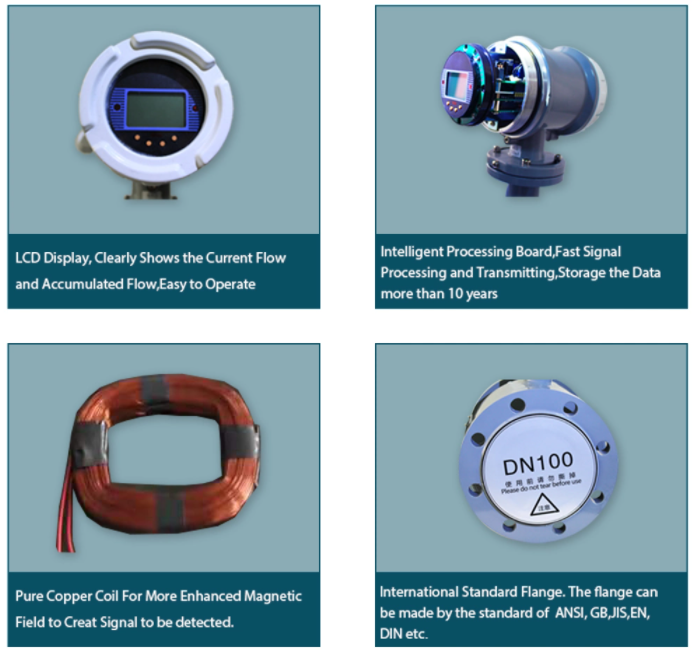

▲The converter adopts 32-bit embedded microprocessor, full digital processing, fast calculation speed, strong anti-interference ability, reliable measurement, high accuracy, and the measurement range can reach 1500:1

▲With conductivity measurement function, it can judge whether the sensor is empty or not, with self-check and self-diagnosis function

▲The internal calculator can separately display the forward cumulative flow, reverse cumulative flow and instantaneous flow

▲The plug-in electromagnetic flow meter is easy to install and can open the hole under pressure on the spot without continuous flow. It has absolute installation advantages and price advantages.

| Executive standard | Electromagnetic flow sensor "JB/T9248-2015" |

| Maximum flow rate | 15m/s |

| Fluid conductivity | ≥5μS/cm |

| Precision level | ±0.2% of indicated value, ±0.5% of indicated value |

| Nominal diameter (mm) | 3;6;10;15;20;25;32;40;50;65;80;100;125;150;200;250;3;6 ;10;15;20;25;32;40;50;65;80;100;125;150;200;250;1600;1800;2000;2200;2400;2600;2800;3000 |

| Nominal pressure | 10.0MPa;6.3MPa;4.0MPa;2.5MPa;1.6MPa;1.0MPa;0.6MPa |

| Ambient temperature | Sensor: -25℃~+60℃, converter and integrated type: -10℃~+60℃ |

| Material of signal electrode and ground electrode | 316L; Hastelloy B; Hastelloy C; Titanium; Tantalum; Platinum-iridium alloy; Tungsten carbide |

| Connection flange material | Carbon steel, stainless steel (304, 316/316L) |

| Connecting flange standard | National standard, Ministry of Machinery standard, Ministry of Chemical Industry standard, (American standard, target must be customized) |

| Electrical Interface | M18*1.5、M20*1.5 |

| Shell protection | Whole machine IP65 Sensor IP68 Sensor IP67 Whole machine IP68 |

Converter IP65 Converter IP65 |

| Electrode lining | Material | Scope of application |

| Lining electrode | Neoprene(CR) | 0℃~80℃ non-strong acid, strong alkali, strong oxidizing medium; can detect sewage and mud |

| Polyurethane rubber(PU) | -25℃~60℃; neutral and strong abrasion slurry, coal slurry, mud | |

| Teflon(PFA) | -25℃~140℃ non-abrasive medium; sanitary medium | |

| Polyperfluoroethylene propylene(F46) | -25℃~100℃ non-abrasive medium; sanitary medium | |

| PTFE | -25℃~140℃; strong corrosive medium such as concentrated acid and alkali; sanitary medium | |

| Ceramics(AL2O3) | Chemical Industry; Mining Industry; Food Industry | |

| 316L | Used in water. Sewage or inorganic. Measurement of slightly corrosive medium with organic acid | |

| Hastelloy B(HB) | It has good corrosion resistance to all concentrations of hydrochloric acid below the boiling point and is also resistant to sulfuric acid. Corrosion of non-oxidizing acids, alkalis, and non-oxidizing salt solutions such as phosphoric acid, hydrofluoric acid, and organic acids | |

| Hastelloy C(HC) | It is resistant to oxidizing acids, such as nitric acid. Corrosion of mixed acid, or mixed medium of Ming acid and sulfuric acid; also resistant to corrosion of oxidizing salts such as Fe+++, Cu++ or containing other oxidants, such as corrosion of hypochlorite solution and seawater at higher than normal temperature | |

| Titanium(Ti) | It is resistant to corrosion by sea water, various chlorides and hypochlorites, oxidizing acids (including fuming nitric acid), organic acids, alkalis, etc.; it is not resistant to corrosion by relatively pure reducing acids (such as sulfuric acid, hydrochloric acid), but such as acid When it contains oxidants (such as nitric acid, Fe+++, Cu++), the corrosion resistance is greatly reduced | |

| Tantalum(Ta) | Has excellent corrosion resistance, very similar to glass. Except for hydrofluoric acid, fuming sulfuric acid, fuming nitric acid, and alkali, it is resistant to corrosion by almost all chemical media (including boiling point and hydrochloric acid, nitric acid, and sulfuric acid). Not resistant to corrosion in alkali. | |

| Platinum-iridium alloy | Applicable to almost all chemical substances, but not applicable to aqua regia and ammonium salt | |

| Tungsten carbide | Good abrasion resistance, can be used for the measurement of high abrasive media, such as paper pulp, mineral pulp, etc. |

Please Send Us your Application details

Measuring range , medium, Installation method (flange, thread), Pressure range, Remote transmitter, Level alarm switch

More Model available for all appication, different termperture and pressure!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist

Our technical team will check your specifications and make a best solution for you.