BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

The tuning fork level switch is based on the vibration principle of cantilever beam, specialised in liquid level measurement instruments for vessels, tanks and various pipelines. It adopts the tuning fork as the vibration probe, and uses piezoelectric devices to realise the driving and detection of vibration. When the fork body is in contact with the measured liquid, the resonant frequency of the fork body is obviously reduced, and the change of the vibration frequency is directly reacted on the output signal of the piezoelectric detection device, and the detection circuit discriminates the change of the frequency and outputs a switching signal. The instrument is stable, reliable, maintenance-free, and has a wide range of applications in water conservancy, chemical, environmental protection, food, medicine and other industries. But to make the tuning fork level switch better function, according to the tuning fork level switch operation specification correct operation is essential, for this reason, this paper combines the kaidi KD series tuning fork level switch installation and connection operation specification is introduced as follows.

First, the tuning fork level switch installation operation specification

Before installing the tuning fork level switch for solids, it should be reconfirmed that the instrument model meets the environmental requirements of process pressure, process temperature, chemical properties of the medium, etc. on site to ensure that the instrument can be used normally after installation.

Generally, KD series tuning fork level switches can be installed in any position according to the need, either horizontally, vertically or inclined. When the measured medium is viscous, the instrument should be installed vertically in order to reduce or avoid the phenomenon of hanging material.

1. Installation direction

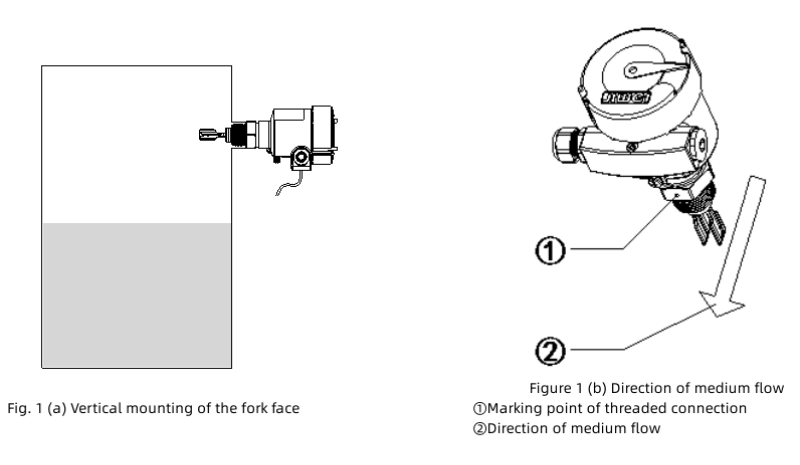

In the installation of KD series tuning fork level switch, in order to avoid hanging material or due to the resistance of the medium to the fork body and the resulting measurement error, should make the fork face and the liquid lift or flow to maintain the same direction, as shown in Figure 1 (a), 1 (b) shows that

2. Avoiding the material inlet

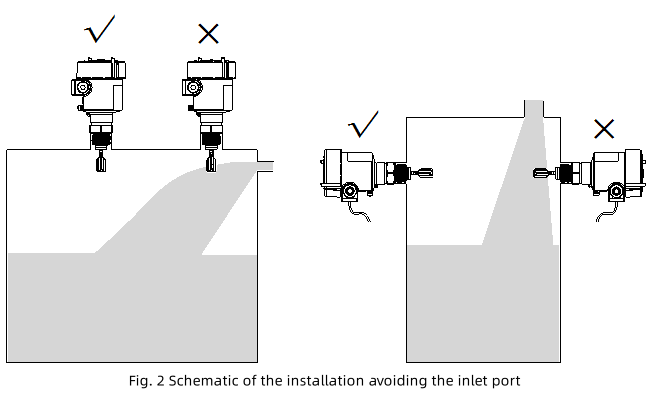

As shown in Fig. 2, when choosing the installation position of KD series tuning fork level switch, the measurement error caused by installing in the position of material inlet should be avoided, and even damage to the instrument should be avoided.

3. Pressure/vacuum

For over-pressure or under-pressure vessels or piping, it is important to ensure that the sealing integrity of the process connection is maintained. Therefore, before installation, it should be confirmed that the sealing material meets the requirements of the process temperature and process pressure on site.

4. Moisture protection

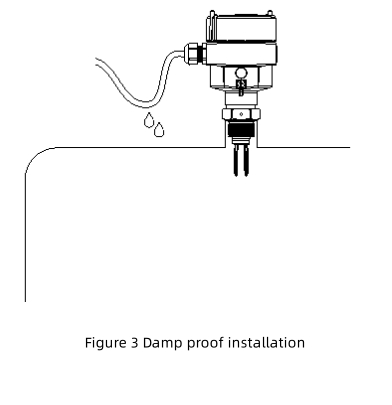

When the tuning fork level switch is installed outdoors or in a humid environment, such as rain or in the condensation phenomenon, rain and condensate will then flow downwards, in order to prevent water or moisture from entering the instrument, before accessing the cable, the cable line should be bent and led downwards, as shown in Figure 3.

Tuning fork level switch operation specification

Second, the tuning fork level switch connected to the operating specifications

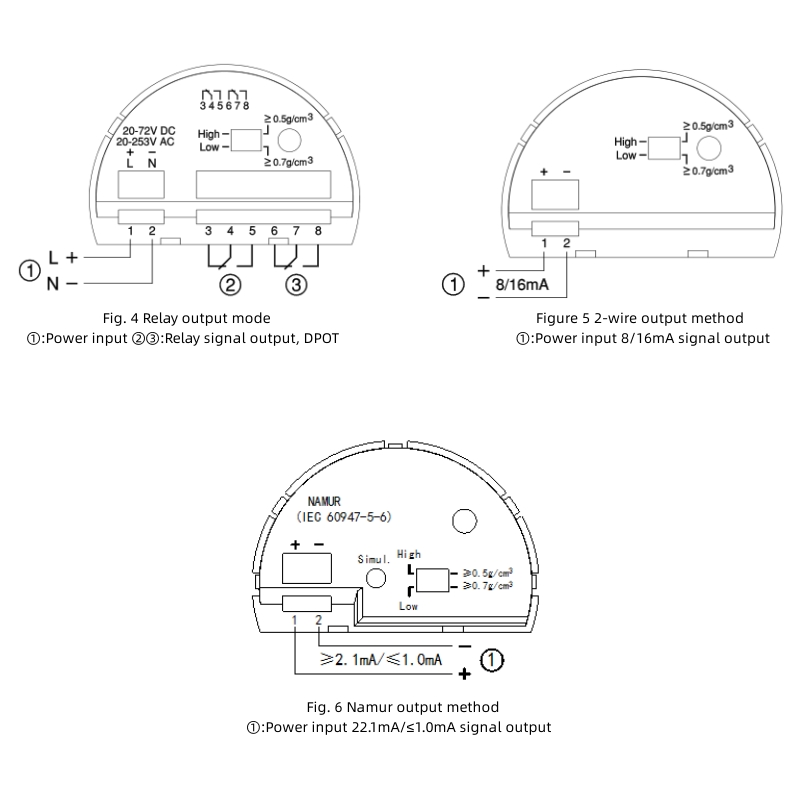

The power connection of the tuning fork level switch is also an important part. Correct and safe wiring is a prerequisite for normal operation of the tuning fork level switch. Generally speaking, the tuning fork level switch should be connected in accordance with the following operating instructions.

1. Safety instructions

From a safety point of view, wiring can only be carried out in the event of a power failure; in the case of explosion-proof tuning fork level switches, the relevant explosion-proof wiring requirements must be followed when wiring.

2. Access cable

The cable for the KD series tuning fork level switches is generally a universal cable with a round cross-section. The diameter of the cable cross-section is 5-9 mm, otherwise the sealing of the cable inlet cannot be ensured.

If you need to use other specifications of the cable, you should use the matching cable inlet bolt, and pay attention to the sealing performance of the cable inlet after replacement.

3. Wiring diagram

When wiring, it should be safely wired as shown in Figures 5, 6 and 7.

4. Wiring procedure

Generally speaking, when wiring the tuning fork level switch, the following steps should be followed:

(1) Open the housing cover;

(2) Loosen the lock nut on the cable threaded connector;

(3) Remove approximately 10cm of the outer jacket of the connecting cable and approximately 1cm of insulation from the end of the core;

(4) Insert the cable through the cable threaded fitting into the housing;

(5) Open the terminals with a screwdriver;

(6) Insert the end of the core cable into the terminal block according to the wiring diagram;

(7) Tighten the terminals with a screwdriver;

(8) Check that the wiring is secure by gently pulling on the accessed cable wires;

(9) Tighten the lock nut of the cable threaded connector and fasten the sealing ring;

(10) Screw on the housing cover.

It should be noted here that for explosion-proof tuning fork level switches, opening the outer cover for operation is only permitted when there is no gas or dust in the environment that would cause detonation.

The KD series tuning fork level switches are highly reliable control switches for liquid level measurement. With a tuning fork length of only 40mm, it is not only suitable for level measurement in vessels, tanks and vats, but also for level measurement in narrow spaces such as conduits. At the same time, based on the design tuning fork level switch working principle of detecting changes in vibration frequency when the fork body is immersed in the medium, the fork body is precisely tuned, and the product can measure the density of the medium as low as 0.5g/cm³, which is not only suitable for the measurement of the level of hydrochloric acid, sulphuric acid, nitric acid, lye, molasses, medicinal liquids, industrial wastewater, etc., but also especially suitable for high-pressure liquefied gases (e.g., LNG), as well as complex measurement occasions with foams, air bubbles, viscous liquids, and vibration interferences. Measuring occasions. As long as the installation and wiring are carried out in strict accordance with the above operating instructions, the tuning fork level switches can be better used for liquid level measurement and monitoring.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist