BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

If a pressure sensor is exposed to a manufacturing environment that exceeds the limits specified by the supplier during storage or assembly, the sensor can become faulty. The following six factors are summarised as noteworthy

1. Temperature

Excessive temperatures are one of the common causes of many problems with pressure sensor rs485, as pressure sensors have many components that can only function properly within specified temperature ranges. During assembly, sensors may be negatively affected if they are exposed to environments outside of these temperature ranges.

For example, if the pressure sensor is installed close to a steam line that generates steam, the dynamic performance will be affected. The correct and simple solution is to move the sensor to a location away from the steam line.

2. Voltage Spikes

Voltage spikes are short-lived voltage transients. Although this high-energy surge voltage lasts only a few milliseconds, it can still cause damage to the sensor. Unless the source of the voltage spike is obvious, such as from lightning, it is extremely difficult to detect, and OEM engineers must be aware of the potential risk of failure throughout the manufacturing environment and beyond. Prompt communication with us can help identify and eliminate such problems.

3、Fluorescent lighting

Fluorescent lamps require high voltage to generate an arc to break through the argon and mercury during start-up, which heats the mercury to a gaseous state. This start-up voltage spike can pose a potential hazard to the pressure sensor. In addition, the magnetic field generated by fluorescent lighting may induce a voltage on the sensor wires that the control system may mistake for an actual output signal. Therefore, sensors should not be placed under or near fluorescent lighting fixtures.

4, EMI / RFI

Pressure sensors are used to convert pressure into an electrical signal and are therefore susceptible to electromagnetic radiation or electrical interference. While sensor manufacturers have made every effort to ensure that sensors are protected from the adverse effects of external interference, some specific sensor designs should reduce or avoid the effects of EMI/RFI (Electromagnetic Interference/Radio Frequency Interference).

Other EMI/RFI sources to avoid include contactors, power cords, computers, walkie-talkies, mobile phones, and large machinery that generates changing magnetic fields. The most common methods of reducing EMI/RFI interference are shielding, filtering and suppression. For proper preventive measures, you can consult us.

5. Shock and vibration

Shock and vibration can cause a variety of problems such as dented housings, broken wires, cracked circuit boards, signal errors, intermittent failures, and shortened life. To avoid shock and vibration during assembly, OEMs must first consider this potential problem in the designer and then take steps to eliminate it.

The easiest way to do this is to mount the sensor as far away as possible from obvious sources of shock and vibration. Another possible solution is to use vibration shock isolators, depending on the installation method.

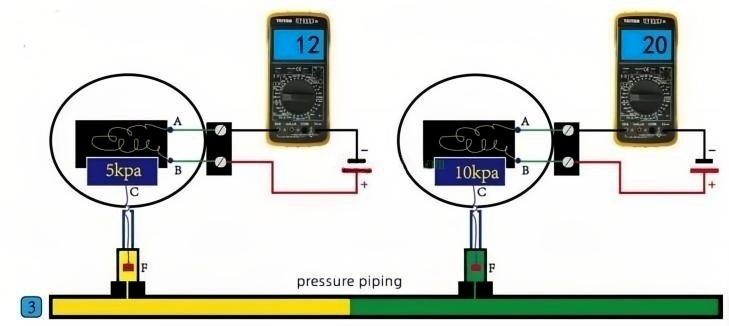

6. Overpressure

Whether at their own manufacturing site or at the end user, once the OEM has completed the machine assembly, care should be taken to avoid overpressure problems. Overpressure can occur for a variety of reasons, including water hammer effects, accidental heating of the system, and failure of the voltage regulator.

If the pressure value occasionally reaches the upper limit of pressure resistance, the 4 20ma pressure sensor can still withstand and will return to its original state. However, when the pressure value reaches the rupture pressure, this can cause the sensor diaphragm or housing to rupture, resulting in leakage. Pressure values between the upper pressure limit and the rupture pressure can cause permanent deformation of the diaphragm, resulting in output drift.

To avoid overpressurisation, OEM engineers must understand the dynamics of the system and the limits of the sensor. During design, they need to grasp the interrelationships between system components such as pumps, control valves, counterbalance valves, check valves, pressure switches, motors, compressors, tanks, and more.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist