BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

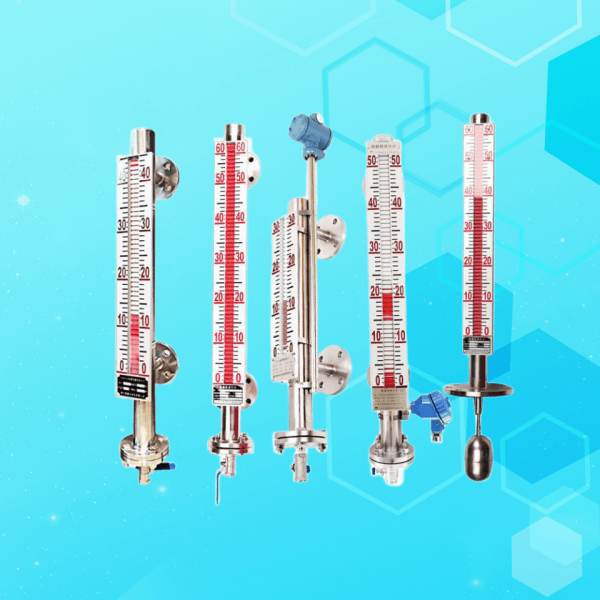

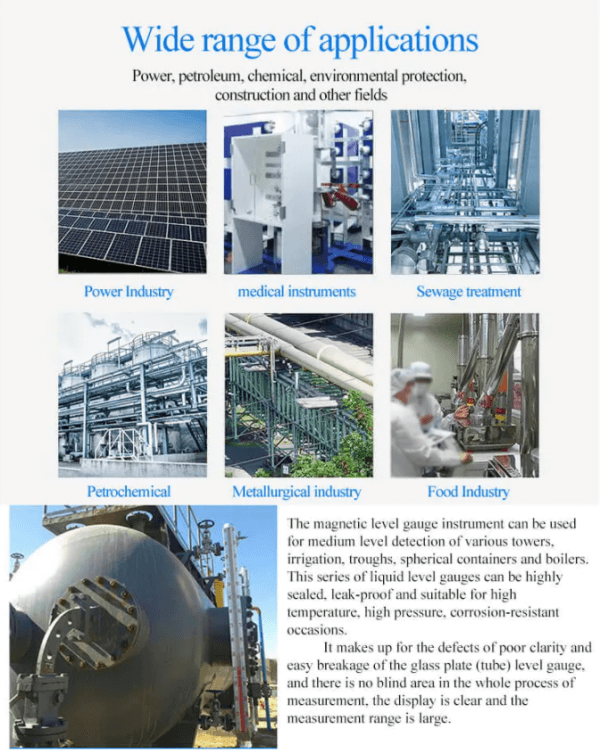

Magnetic flap level meter is a device that uses the principle of linker, buoyancy principle and magnetic coupling principle to display or detect the height change of liquid level, and is also a common instrument for measuring liquid level in industrial production. It is suitable for liquid level measurement under high pressure, high temperature and corrosive conditions, and has wide application in liquid level measurement in petroleum processing, municipalities, food processing, water treatment, chemical, pharmaceutical, electric power, paper making, metallurgy and other fields. However, due to the differences in the use of environment and mode, as well as some magnetic flap level gauge due to unreasonable design or improper operation during installation and use, the magnetic flap level meter can not be measured normally in the process of use, thus affecting the normal production, and even threatening the safety of production. Therefore, it is important to find the factors affecting the normal measurement of the magnetic flap level meter and to avoid the recurrence of such incidents. This article combines the characteristics of the magnetic flap level meter and discusses the common factors affecting the normal measurement of the magnetic flap level meter encountered in the field application process.

1、Using environment

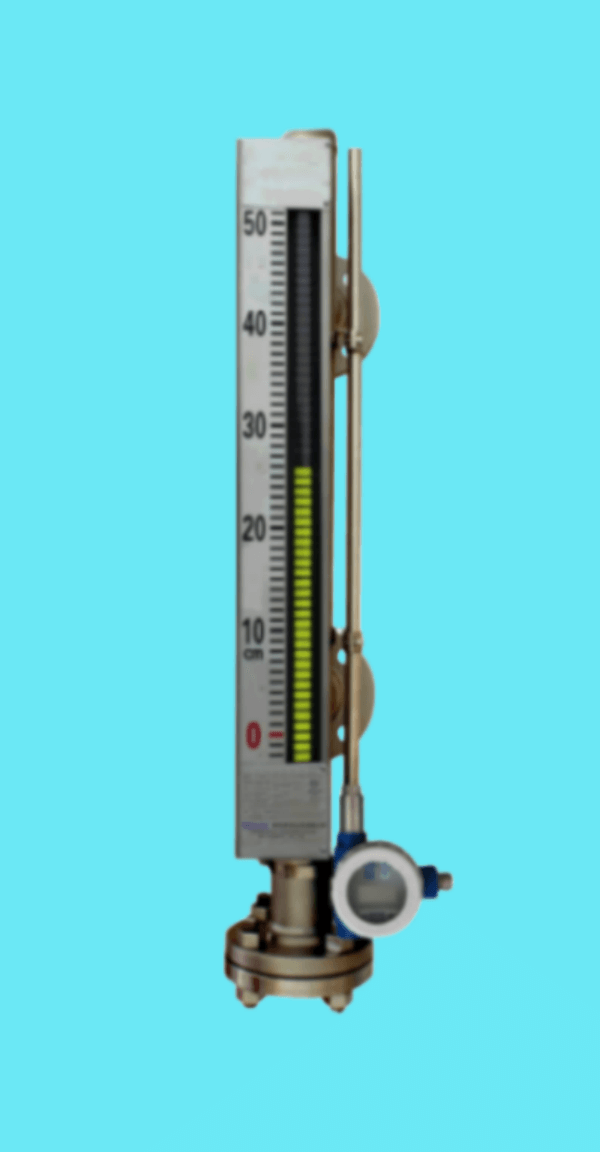

The magnetic mflap mainly uses the buoyancy and magnetic coupling to complete the indication process. When the liquid level rises, the magnetic float moves from down to up under the action of buoyancy, and the magnetic flip flop is flipped 180° by the magnetic induction force in the magnetic float, and the color changes from white to red, and the red and white dividing position of the flip flop on the display panel is the actual height of the liquid level of the tank.

Therefore, there should not be strong magnetic interference in the environment, otherwise the magnetic flip flop will not be able to flip normally and affect the accurate display of liquid level. In addition, in the installation of the magnetic flip-flop level meter, do not use wire or itself with magnetic material fixed magnetic flip-flop level meter float, so as to avoid the magnetic float floating up and down by the wire or the magnetic material impact.

2、Improper installation

The installation position of the magnetic flip-plate level meter must be perpendicular to the ground. This is because the activity of the magnetic float is mainly affected by buoyancy and its own gravity, so if the overall installation of the magnetic flap level meter is tilted, it will increase the friction between the magnetic float and the pipe wall, affecting the normal movement of the magnetic float. In addition, the magnetic flap level meter in the installation process due to its overall weight, the side and tank connected to the diversion tube force, so in the range of larger (generally more than 3m) must be installed in the middle of the auxiliary support device to reduce the diversion tube force. In addition, if there are some metal impurities in the measured liquid, long time use will make impurities deposited in the bottom of the float or adsorbed in the surface of the magnetic float, which requires regular cleaning of its interior. When cleaning the magnetic flap level meter, the valve connected to the diversion pipe should be closed first, and then open the drain valve for drainage, and if necessary, the bottom flange can be disassembled for cleaning. After cleaning, it should be installed according to the original way, with the heavy end of the magnetic float facing upward and the flange bolts tightened.

3、Low temperature environment

The use of magnetic float type level gauge environment is mostly outdoor, especially in the colder areas, if the temperature is too low can also lead to measurement failure. To solve this problem, usually use steam jacket, electric heating, insulation / thermal insulation additional devices. In winter, if the material is affected by the low temperature environment, the whole panel becomes waterproof, and once water vapor or rainwater penetrates into the panel, it will cause the magnetic flip flop to freeze or the glass surface of the panel to frost, and the operator cannot correctly determine the exact location of the liquid inside the tank. Therefore, the glass tube panel becomes an effective way to solve this problem, by fixing the magnetic flip-flop inside the glass tube and then vacuuming or filling with inert gas, and finally sealing the glass tube. This method can completely solve the problem of waterproof and frost-proof panels, but its disadvantage is the high cost, and complex operation process, easy to break.

4、Corrosive environment

In the chemical industry for measuring a variety of corrosive liquids, it is necessary to use anti-corrosion type or lined magnetic flap level meter. More is through the metal tube and magnetic float surface lined with polytetrafluoroethylene (PTFE), the use of polytetrafluoroethylene measured liquid and metal tube separated to achieve anti-corrosion purposes. PTFE has good corrosion resistance and mechanical toughness, not easy to mechanical damage during processing, and for most chemicals and solvents, showing inertia, strong acid and alkali, water and a variety of organic solvents. Although the melting point of PTFE is high, can be used in 250 ℃ working conditions, but because of its own expansion coefficient is relatively large, and with the temperature change and irregular changes, if long-term use in high temperature environment will lead to its deformation in the inner wall of the pipe, and even magnetic float stuck in the inner wall of the pipe, so it must be used in strict accordance with the magnetic flap level meter design parameters. Therefore, the magnetic flap level meter should be regularly maintained and certain protective measures should be taken to prevent its uneven force or other causes of failure and safety accidents.

5、Current signal and switch signal

In some occasions, users need to convert the measurement results into current signals to the central control room, to facilitate monitoring and control, it is necessary to use with remote transmitters to achieve the purpose of converting mechanical signals into current signals. In the whole process of use, when the transmitter is installed to try to make its position does not change, because once the position changes, easy to make the current signal output error. Therefore, for the tank has vibration conditions, should take fixed protection measures.

Liquid level measurement as an important link in industrial production, magnetic flap level meter as one of the commonly used means, which requires the magnetic flap level meter must be safe and reliable, production process and testing standards, by focusing on process details, strict control of the production process and quality testing, to overcome the defects and common failures of peer products at home and abroad, to ensure that the product has a very high reliability. In addition, the user in the use of the process should also be strictly in accordance with product specifications, to ensure the safety of production as the first priority, to ensure the accurate measurement of the magnetic flap level meter and durable.

The above is the introduction of "magnetic flap level meter normal measurement factors", if you want to know more level switch (level switch, liquid level switch), level meter (level meter, liquid level meter) and other level measuring instrument knowledge, welcome to pay attention to and contact us!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist