BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Flange connection can be said to be ubiquitous, but in the selection and installation process need to pay attention to the matter, I summarize, we look at the scene to see if they encountered such problems

1. When the working temperature is lower than 20℃, the maximum allowable working pressure of the flange shall be the value at 20℃. When the working temperature is higher than the upper limit of the listed temperature,

the maximum allowable working pressure can be determined by the designer according to the experience or calculation.

2. If a flange connector of two flange components with different pressure ratings, the maximum allowable working pressure value of the joint is determined by the lower, and should control the installation of the stud torque to prevent

over-tightening. For example, the valve end flange is stainless steel, supporting the flange is aluminum, then it is necessary to consider its maximum allowable working pressure value according to the lower.

3. Determine the pressure-temperature rating of the flange joints, should be considered at high or low temperatures in the piping system of the external force and external torque on the sealing performance of the flange

joints.

4. Flange joints with high temperature variation range or subjected to large temperature gradient should take measures to prevent bolt relaxation, such as regular tightening. Under low temperature operation conditions, it should be ensured that the material has sufficient toughness, cold tightening at low temperature, etc.

5. Plate type flat welding flanges, threaded flanges, butt-welding ring loose flanges and flat welding ring loose flanges should not be used in severe cycling conditions.

6. Under severe cycling conditions, necked butt-welding flanges or integral flanges should be used.

7. Threaded flanges and socket weld flanges should not be used where crevice corrosion or severe corrosion may occur.

8. Nominal pressure less than or equal to PN40 steel flanges and cast iron flanges should be connected with the sealing surface of the full plane (FF) type, gaskets should be full plane non-metallic flat gasket, such as the use of protruding surface sealing surface and protruding surface non-metallic flat gasket, should be controlled on the tightening torque, to prevent over-tightening.

9 with the nominal pressure greater than or equal to PN40 valve with the valve on the whole flange such as concave surface, the pipe flange sealing surface should be convex.

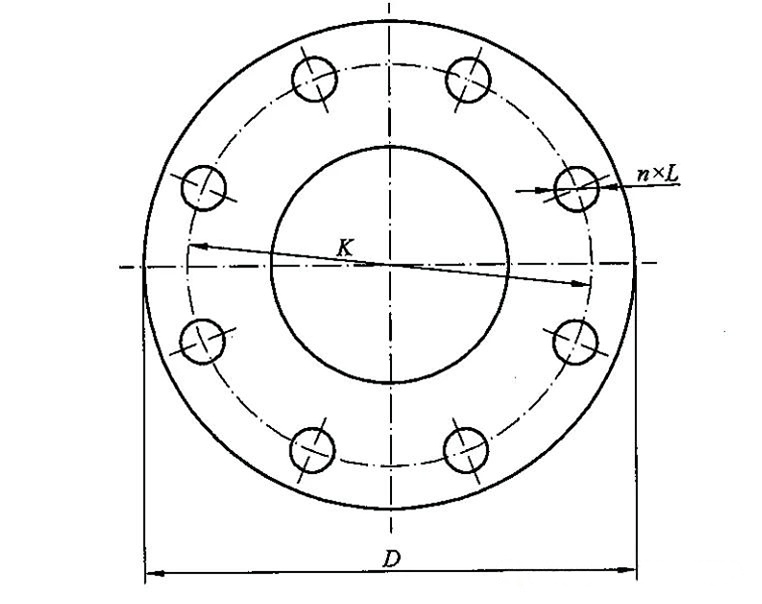

1. Bolt hole drilling requirements are equally spaced to the center line shall prevail, symmetrical center line according to a certain angle of distribution.

2. Installation of piping requirements

When installing the pipeline, you need to ensure that the center of the pipeline and the center of the single flange can not be too large, according to the size of the pipeline to reasonably control its deviation.

3. Installation fastening sequence requirements

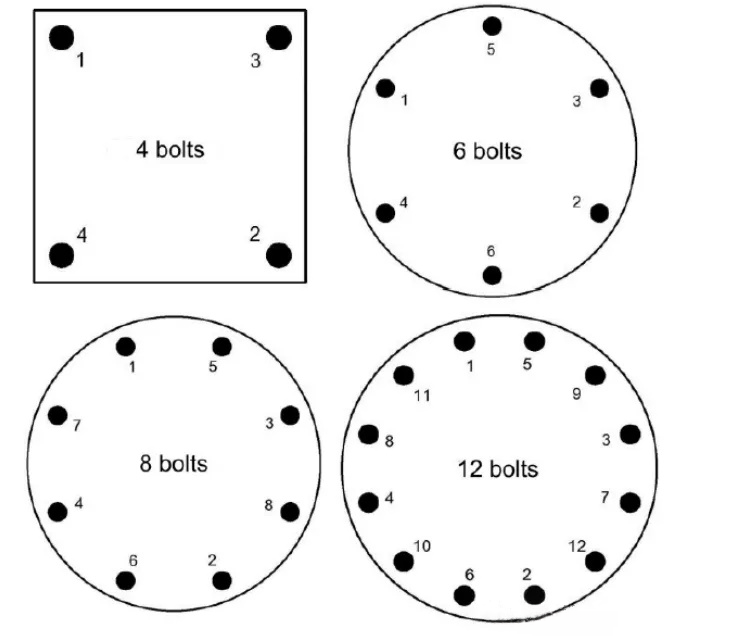

Use suitable tightening tools, according to the provisions of the torque table provided by the company, in a crosswise manner (as shown in the figure below) in accordance with the clockwise direction of the tightening bolts, tightening steps are as follows:

①. Tighten all nuts by hand (larger nuts require a smaller wrench)

②. Tighten each nut in a crosswise manner to about 30% of the full torque.

③. Tighten each nut in a crosswise manner to about 60% of the full torque.

④. Tighten all nuts in a crosswise manner to the full torque until there is no further rotation of the nut (larger diameter flanges require more tightening).

⑤. Tighten again.

Bolts used in frequent thermal cycling or at normal or low temperatures need to be cross-tightened again until the provided torque value is reached or the nut will not rotate further. The pre-tightening operation is usually carried out after bare cooling and it is recommended that the re-tightening operation should be carried out at room temperature and at atmospheric pressure.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist