BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Diesel Level Gauge, a pressure sensor for measuring liquid level, is suitable for level measurement of various media in petrochemical, metallurgical, electric power, pharmaceutical, water supply and drainage, environmental protection and other systems and industries. And, with the magnetic flap level gauge market has been growing continuously in recent years, the development prospect of the level gauge sensor industry is very good.

The working principle of the level transmitter is that when the two pressures of the measured medium are passed into the high and low pressure chambers, they act on both sides of the isolation diaphragm of the sensitive element, and are transmitted to both sides of the measuring diaphragm through the isolation piece and the filling liquid inside the element.

The (float) level transmitter is a capacitor consisting of a measuring diaphragm and an electrode on each side of the insulating piece. When the two sides of the pressure is not consistent, resulting in the measurement of the diaphragm displacement, its displacement and pressure difference is proportional to the two sides of the capacitance is not equal, through the oscillation and demodulation link, converted into a signal proportional to the pressure. The working principle of pressure transmitter and pressure transmitter is the same as that of differential pressure transmitter, the difference is that the low pressure chamber pressure is atmospheric pressure or vacuum.

The A/D converter converts the current from the demodulator into a digital signal, the value of which is used by the microprocessor to determine the input pressure value. The microprocessor controls the operation of the transmitter. In addition, it performs sensor linearization. Resets the measuring range. Engineering unit conversion, damping, open square,, sensor trimming and other operations, as well as diagnostics and digital communications.

This microprocessor has 16 bytes of program RAM and has three 16-bit counters, one of which performs the A /D conversion.

The D/A converter takes the microprocessor and corrects the digital signal trimming data, which can be modified by the transmitter software. The data is stored in EEPROM and remains intact even in the event of a power failure.

A digital communication line provides the transmitter with an interface to external devices such as the Model 205 Intelligent Communicator or control systems utilizing the HART protocol. This line detects the digital signal superimposed on the 4-20 mA signal and transmits the required information through the loop. The type of communication is frequency shifted keying FSK technology and is based on the BeII202 standard.

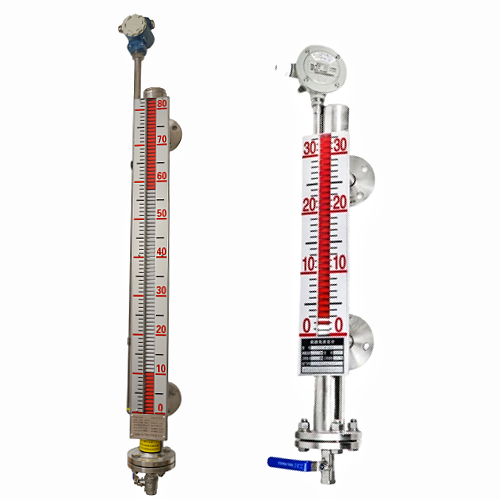

Then, on the 3 major liquid level guage for everyone to explain

1, Float type diesel level meter:

Float level transmitter is to change the magnetic float to float, the level meter is designed according to Archimedes buoyancy principle. Float level transmitter is the use of tiny metal membrane strain sensing technology to measure the liquid level, boundary level or density, it can work through the field key to set the routine operation.

2、Float type diesel level meter:

Float level transmitter by the magnetic float, measuring conduit, signal unit, electronic unit, junction box and mounting components, the general specific gravity of the magnetic float is less than 0.5, can be floated above the liquid surface and move up and down along the measuring conduit, the conduit is equipped with a measuring element, which can be measured under the action of the external magnetic will be converted into a level signal proportional to the level of resistance signal, and will be converted to the electronic unit into a 4 ~ 20mA or Other standard signal output.

3, hydrostatic diesel level meter:

The transmitter uses the liquid static pressure measurement principle work, it is generally used silicon pressure pressure sensor will be measured pressure is converted into an electrical signal, and then amplified by the amplifier circuit amplification and compensation circuit compensation, and then to 4 ~ 20mA or 0 ~ 10mA current output.

The use of liquid level meter is more widely used, to our life and work have brought great influence, in order to correctly use the liquid level transmitter, you need to have some understanding of its classification.

Frequently Asked Questions and Precautions

Liquid level meter is the high and low two liquid level (vapor condensed into liquid through the small steam bag) formed by the pressure, sent to the transmitter in the detection of the two ends of the diaphragm, detection of differential pressure, and then transformed into a 4 ~ 20mA current signal output to the DCS host computer, after the calculation of the re-conversion for the level signal to the CRT. when the CRT due to the value of the error and can not control the system's water supply, you should go to the site to check, verify and adjust the actual water level. Input pressure diaphragm sensor electrostatic capacity change detection section determination circuit operation amplification circuit output current transmission section.

Specific steps are as follows:

1, open the upper end of the transmitter two drain holes for vapor exhaust work, because the central control level signal distortion in addition to the

In addition to the fault of the transmitter itself, generally for the detection of medium condensate contains vapor bubbles or impurities lead to detection signal deviation, so open the transmitter on the two drain holes for the exhaust work until there is a continuous liquid spray. This step to adjust the liquid level of the steam packet, should pay attention to notify the central control of the steam packet level control will be switched to another alternate control level (PH furnace LI404 and LI405, AQC furnace LI304 and LI305), in order to prevent the central control of the liquid level of the value of the emergence of large-scale, violent fluctuations and lead to automatic control failure. In addition to adjust the level of the flash evaporator, because the flash evaporator is a single series of liquid level meter, so the adjustment should be more slowly and carefully.

2, if the first adjustment effect is not good, you can open the transmitter piping on a small amount of sewage valve for sewage work, this work should pay attention to the operation of the safety, the valve should be opened slowly, to prevent possible scalding caused by steam.

3, if the site glass plate water level meter and the central control of the liquid level value difference is very large, can not be sure that the site glass plate water level meter for the real water level, the site glass plate water level meter should be flushed, adjusted to prevent the site glass plate water level meter due to the mixture of steam and water or the valve impurities caused by the blockage of the site liquid level display distortion.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist