BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

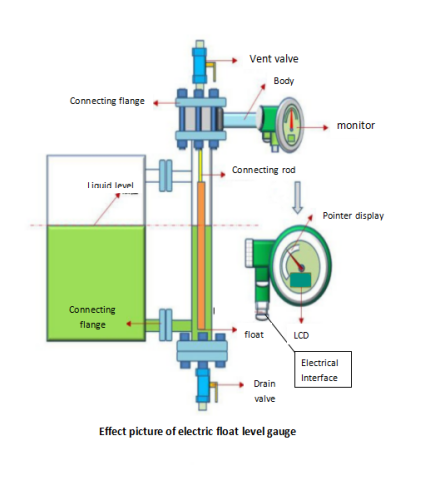

The magnetic flap level meter can realize the purpose of local display and remote (with remote transmitter) liquid level measurement. For different measurement environments and working conditions, the adaptability of the magnetic flap level meter can be greatly enhanced by the addition of suitable components. Among the many parts of the magnetic flap level gauge, the flange valve is a very important structural part of the magnetic flap level meter. But in the long-term use process, if you do not know the maintenance and maintenance or improper methods, the flange valve of the magnetic flap level meter will also produce various failures, which requires regular maintenance and cleaning. So, how should the maintenance and repair of the flange and valve components of the magnetic level gauge be carried out?

A, the flange sealing surface maintenance and maintenance

1, flange sealing surface with dirt. Maintenance and maintenance methods: clean the sealing surface.

2, the flange sealing surface is damaged. Treatment: repair or replace the sealing surface.

Second, the flange part of the leakage failure and processing

1、Gasket damage or failure. Treatment: Replace the gasket.

2、Dirt is hidden between the sealing surface of the flange. Treatment: Remove the flange and clean.

3, flange connection bolts are not tightened or unevenly tightened. Treatment: Loosen the bolts and tighten them again evenly and symmetrically.

Third, the stuffing box leakage failure and processing

1、Flange packing failure. Treatment: Replace the packing with new one.

2, packing loose or packing gland pressure deviation. Treatment: the packing gland should be evenly pressed.

Fourth, the valve stem operation inflexible fault and processing

1, spool cover joint angle is too tight or bearing wear. Treatment: adjust the packing tightness or replace the bearing.

2, the stem or stem nut between the debris or dust, the stem or stem nut is damaged. Treatment: disassemble and clean the stem, if damaged, replace the stem or stem nut.

3、The opening and closing device is faulty. Treatment: check the fault according to the device instructions and repair.

The above is the "magnetic flap level meter flange and valve and other parts of the maintenance and maintenance" related to the introduction, such as to learn more level switch (level switch, level switch), level meter (level meter, level meter) and other level measurement instrument knowledge, welcome to pay attention to and contact us!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist