BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

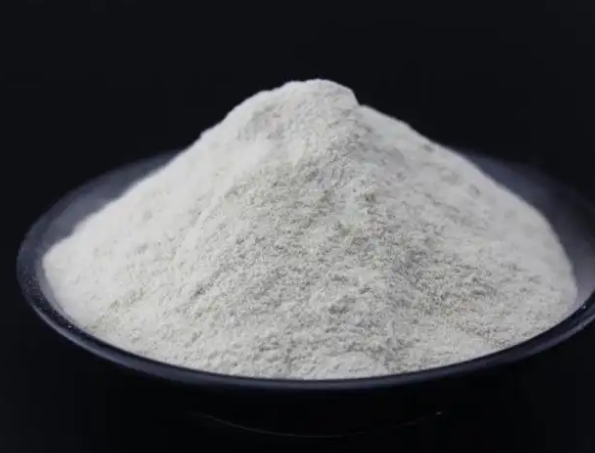

In the large-scale process automation production, each link has different material level measurement needs, and the characteristics of materials in different processes are also very different. For example, carbon black industry, wet granulation needs to add water in the production process, and then high temperature drying process, so add water before and after the addition of water to the viscosity of the material is a big difference; iron and steel, metallurgy, thermal power industry, desulfurization and denitrification process links in order to deal with the sulfide and nitrogen compounds in the flue gas after dedusting will be sprayed with limestone powder, stored in the limestone silo of the material will have a certain degree of viscosity, plus 120 ℃ or even higher process temperature, exacerbating the material agglomeration; lithium industry, battery materials such as lithium iron phosphate, lithium hydroxide, lithium carbonate, etc. The material itself has poor mobility and strong hygroscopicity, due to viscous and easy to agglomerate. For this characteristic of the material level detection, taking into account the tank structure and the need for control linkage, in addition to continuous measurement of the material level, requires the addition of switching instrumentation as a limit alarm. Measurement of viscous powder has always been the difficulty of level measurement instrument, for viscous powder level measurement, how to choose the right level switch becomes the key to solve the difficulty.

Viscous Powder

Instruments that can adapt to viscous material level measurement are few, and to achieve stable, long-lasting and reliable measurement, they must be selected according to specific working conditions.

Level measurement can be divided into contact measurement and non-contact measurement according to whether it is contact or not. For viscous powder conditions, the relatively mature and reliable measurement method is non-continuous contact measurement, mainly rotary level switches, capacitive level switches and vibration level switches represented by tuning forks and vibrating rods.

The advantage of the rotary level switch is that the motor drives the spindle to rotate, and the blade is not sensitive to the material hanging, but when used to measure the hygroscopic powder, due to the sealing of the rotating shaft can not be avoided in the spindle end cover gap will be seepage of material in the high-temperature powder with the pressure of the silo, the shortcomings of this is more prominent, not only will the rotating shaft jamming, high temperature powder ash is also easy to enter the table head leading to the motor burned out.

Resistor level switch similar to the rotary level switch, in order to ensure the sealing performance of the product, the rotation angle of its blade is not 360 °, but to a certain angle of the swing back and forth, the service life of the relative rotary level switch will be a little longer, but the limitations of its own mechanical structure of the sealing is poor, the problems encountered on the rotary level switch in the resistor level switch on the body of the same can not be avoided.

Capacitive level switch by detecting changes in capacitance between the probe and the container wall output level control signals, its main advantage is reflected in the material used in the probe of the PTFE rod of strong corrosion resistance, in the lithium industry can be avoided to avoid direct contact between the material and the metal. However, if it is used to measure the viscous material, because of its dielectric constant changes, easy to scar on the probe, also can not realize the measurement of such materials.

Radio frequency conductive material level switch is developed on the basis of capacitive type, increasing the anti-hanging material circuit design, to achieve a certain degree of anti-hanging material effect. However, when used to measure viscous materials, also due to its dielectric constant changes, easy to scar on the probe, to avoid frequent false alarms. RF-conductance level switches are mainly used in relatively dry, relatively stable dielectric constant of the gray storage measurement.

Vibrating rod level switch is the use of piezoelectric ceramic drive probe vibration for work, so compared with radio frequency conductivity and capacitive level switch, its main advantage is to maximize the avoidance of material in the probe hanging material, this vibration level switch measurement principle has nothing to do with the dielectric constant of the medium. Unlike the single rod structure of vibrating rod level switches on the market, the probe of the vibrating rod level switch adopts the double tube structure nested inside and outside, and achieves the resonance state after precision tuning, which can maximize the performance of anti-hanging material. Ordinary single rod structure vibrating rod level switch, because of its single rod structure can not realize the probe resonance, especially sensitive to hanging material, even if the slight hanging material will output false alarm signal; due to the inability to resonate, the single rod probe on the low-density media poor perceptibility, can not be measured; single rod structure vibration is difficult to its piezoelectric components require a higher driving voltage, resulting in short life, poor reliability of the instrument.

From the point of view of anti-hanging material, sealing, independent of the dielectric constant of the medium and sensitivity, the double tube vibrating rod level switch is currently the more ideal choice for viscous powder level measurement. Of course, it does not mean that the double bar vibrating rod level switch can be applied to all kinds of viscous material conditions, such as in the easy to caking and scarring of the material also has its limitations, especially installed in the low and high temperature environment, for the vibrating rod level switch is also very challenging, then we generally recommend to increase the auxiliary measures to slow down this hanging material, such as adding regular blowing.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist