BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

How about determining whether instrumentation in industry meets the requirements for explosion protection? This is a worthwhile learning point for users who need to use explosion-proof products or for partners who need to know about level instruments. The following Kaidi Energy Technology Co., Ltd. to introduce you to the relevant aspects of knowledge points!

At present, in many complex working conditions of the application site, the instrument must be a product with explosion-proof function. In general, explosion-proof products can meet most of the explosion-proof requirements. However, due to the variety and quality of products on the market industrial instrumentation varies, explosion-proof products mixed, it is difficult to distinguish the real from the fake. Therefore, in the actual selection, how to quickly identify whether the instrument meets the requirements of explosion-proof is very important. Here, according to the author's experience in product design, three methods to determine whether industrial instruments meet the requirements of explosion-proof.

A, the appearance of identification method

Appearance identification method, that is, through the appearance of the instrument, the initial determination of whether to meet the requirements of the explosion-proof. There are several specific places to identify the following.

(1) nameplate identification: whether the instrument's nameplate has Ex explosion-proof symbol, whether the parameter description of the explosion-proof level description.

(2) Glan head (cable entrance): Flameproof glan head should be made of metal (such as stainless steel, brass, etc.).

Second, the explosion-proof certificate identification method

Explosion-proof instruments have the corresponding explosion-proof certification. To determine whether the instrument meets the explosion-proof, you can inquire at the third-party website of explosion-proof certification. If the product model matches the actual product, it means that it meets the explosion-proof requirements, and vice versa.

Third, the technical verification method

Technical verification method, that is, through the basic definition of explosion-proof, from the shell size and structure of the initial identification of the instrument to meet the requirements of explosion-proof.

According to the standards and requirements of industrial instrumentation explosion-proof, explosion-proof instrumentation is defined as follows.

(1) electrical equipment enclosures that can withstand the dangerous pressure of the internal hazardous gas mixture and prevent the propagation of the internal hazard to the hazardous mixture around the enclosure (Zone I explosion-proof technology).

(2) allows hazardous gases to enter the explosion-proof enclosure, which may create a hazard within the enclosure. However, the enclosure must be of sufficient strength; and each enclosure joint must have a long enough engagement length and a small enough gap to ensure that the internal hazard does not pass through the explosion-proof joint and result in an external environmental hazard.

(3) is the gap explosion-proof technology, relying on the gap, the length of engagement to achieve the effect of cooling, flameout.

From the definition, it can be seen that the requirements of the explosion-proof is mainly for the instrument housing, our initial judgment can be achieved by the number of screw teeth on the housing cover, in accordance with the requirements of the explosion-proof, screw teeth to meet the 5 teeth and the total engagement length of 8 mm can be.

The above three methods of determination are very effective in verifying that industrial instrumentation products meet the requirements of explosion isolation.

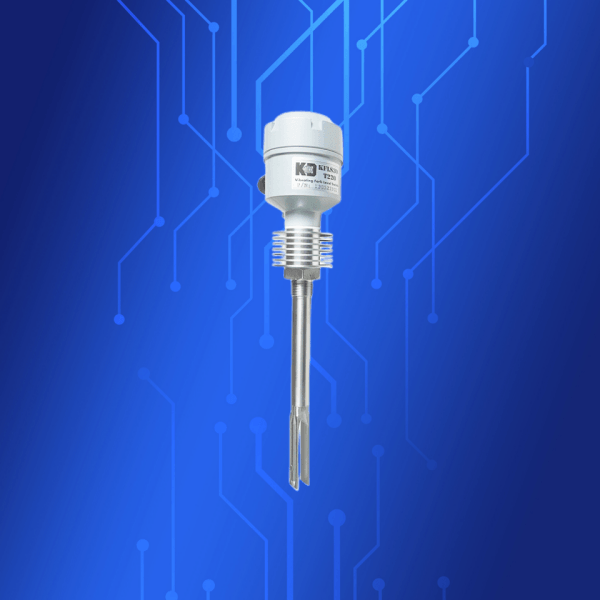

For rotary level switches, especially for tuning fork level switches, the identification of their explosion-proof function is particularly important. There are too many inexpensive and low quality products on the market, which make it difficult to identify whether they are explosion-proof or not, causing customers to be at a loss when choosing products. Especially in the higher requirements for explosion-proof occasions, if the pursuit of low prices, while ignoring the performance indicators of the product may lead to serious consequences, so it is particularly important to learn to identify whether industrial instruments meet the requirements of explosion-proof.

The above is about how to determine whether the instrumentation in industry to meet the requirements of the explosion-proof? This point of knowledge to explain, if there is anything you do not understand the place or other insights can be left in the comments section to discuss Oh!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist