BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

The working principle is that the motor in the junction box drives the drive shaft and the blade connected to the end of the drive shaft to rotate together when the blade touches the material because of the resistance, the blade stops rotating, prompting the motor to stop rotating when the material drops and the blade resistance disappears, the overall resistance level switch will resume normal operation. When the material drops and the resistance of the blade disappears, the rotary level switch will resume normal work. When the resistance of the material falling blade disappears, the whole level switch will return to normal operation. The resistance level switch has been widely used in chemical, plastic, cement, pharmaceutical, feed, food and other industries, which is inseparable from its many advantages.

A, the advantages of the resistive level switch

1、Simple structure, excellent performance. Simple structure, corrosion resistance, high temperature resistance and dustproof performance, stable and reliable work, low price, high cost performance.

2、Accurate and reliable, easy to install. The rotary level switch can be installed horizontally (slightly inclined) or vertically, using the contact measurement method, accurate and reliable measurement, convenient and easy to use.

3、Stable work, strong adaptability. The rotary level switch has measurement reproducibility and adaptability to environmental conditions, i.e. it is not affected by changes in medium, shape, specific gravity, temperature, humidity, dust concentration, etc.

4、Strong anti-interference, ready to install and use. Because of the simple internal structure of the resistive level switch, there is no complex electronic components and amplifying circuit, it is not subject to any electromagnetic interference, and can be used for a long time without any debugging and maintenance after installation, so it is more trouble-free to use.

5、Overload protection, not easy to damage. The output shaft adopts overload protection device, which can effectively avoid the damage caused by improper use or abnormal external force to the motor and reducer.

Second, the characteristics of the count for the resistance level switch

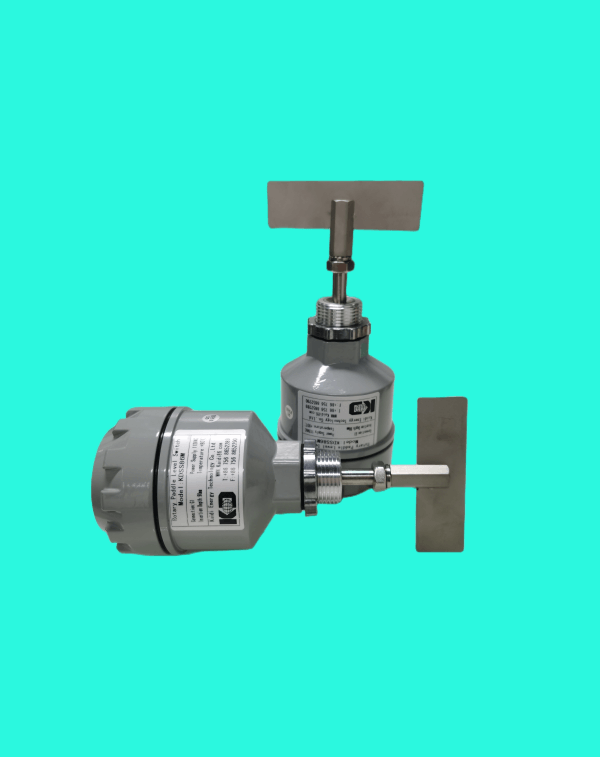

KDSS86 series rotary paddle level switch has the following characteristics in addition to the above advantages common to rotary level switches.

1、Imported motor, integrated design. Imported motor, micro switch and bearing; motor and mechanical control integrated design, easy to replace and repair.

2, anti-loose design, more reliable. Vibration anti-loose structure design, can effectively avoid parts loosening and slipping off.

3、Super anti-shaking, smooth running. Double bearing design, super anti-jitter performance, even when the material flow will not send a wrong signal, smooth operation, long life.

4、High sealing. Super dustproof sealing design, protection grade up to IP65.

5、Double explosion-proof certification. Gas dust double explosion-proof, explosion-proof level of ExdIICT6; ExtDA21IP65T80℃, wide range of application.

6、High quality material, anti-corrosion and wear-resisting. Using high quality 304/316L stainless steel or carbon steel materials, with excellent corrosion resistance and wear resistance.

7、Longer service life. Automatic protection function, so that the resistive level switch in the bin with material blade rotation is blocked, power off does not work to protect the motor and effectively extend its service life.

III. Defects of the rotary level switch

It is these advantages of rotary level switches in material level measurement that make them widely used in the industrial field of material level measurement. However, just as there is no perfect thing, there are also some defects in the resistance level switch itself. Specific performance in the following areas.

1、Rotary level switch is a switch level measuring instrument, which can only measure a certain height point level, but cannot realize the real-time continuous measurement of material level.

2, from the working principle of the rotary paddle type level switch, it is clear that the motor directly determines and affects the stability and reliability of the work of the rotary level switch. In industrial applications, if the motor is not selected properly (such as the use of low-quality motor), it is easy to cause frequent failure of the rotary level switch.

(1) The motor coil is easily burnt out and scrapped.

(2) If the motor torque is insufficient, false alarms often occur.

(3) If the motor quality is light, the self-chattering of the product during operation cannot be eliminated, affecting the stability of the product.

(4) motor reducer device is easy to wear, easy to occur gear bite, or due to parts rupture, the motor can not work.

In order to guarantee the reliability of the product from the root, KDSS86 series of rotary level switch adopts imported motor, micro switch and bearing, and also pays attention to the details of the process, strictly controls the production process and quality inspection, which has higher reliability than similar products in China.

The above is the introduction of "what are the advantages and defects of resistance level switch", if you want to know more level switch (level switch, liquid level switch), level meter (level meter, liquid level meter) and other level measuring instrument knowledge, welcome to pay attention to and contact!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist