BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Why should transmitters and sensors use 4~20mA as transmission signal?

I. What is 4~20mA.DC (1~5V.DC) signaling system?

4~20mA.DC (1~5V.DC) signal system is the International Electrotechnical Commission (IEC): analog signal standard for process control system. Our country from DDZ-Ⅲ type electric instrumentation began to use this international standard signaling system, instrument transmission signal using 4 ~ 20mA.DC, contact signal using 1 ~ 5V.DC, that is, the use of current transmission, voltage receiving signal system.

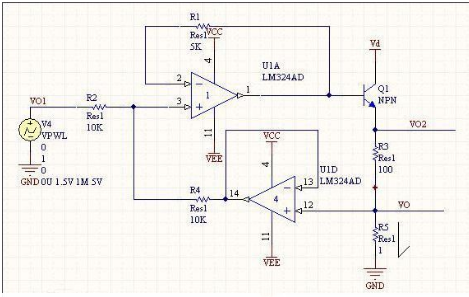

4~20mA current loop working principle:

In the industrial field, using an instrumentation amplifier to complete the signal conditioning and transmit it over a long line will cause the following problems: firstly, since the transmitted signal is a voltage signal, the transmission line will be interfered with by noise; secondly, the distribution resistance of the transmission line will generate voltage drop; thirdly, how to provide the working voltage of the instrumentation amplifier in the field is also a problem.

In order to solve the above problems and avoid the influence of related noise, we use current to transmit the signal, because the current is not sensitive to the noise. 4~20mA current loop is to use 4mA to indicate the zero signal, and use 20mA to indicate the full scale of the signal, and the signal lower than 4mA and higher than 20mA is used for various kinds of fault alarms.

(Image source: Internet)

Second, 4 ~ 20mA.DC (1 ~ 5V.DC) signal system advantages?

Field instrumentation can be realized two-wire system, the so-called two-wire system that the power supply, load in series, there is a common point, and the field transmitter and control room instrumentation before the signal contact and power supply with only two wires. Because the signal starting current of temperature sensor 4-20ma.DC, for the transmitter to provide a static operating current, while the instrument electrical zero point of 4mA.DC, not coincide with the mechanical zero point, this "live zero" is conducive to the identification of power outages and disconnections and other faults. And two-wire system is also convenient to use the safety grid, conducive to safety and explosion-proof.

Control room instrumentation using voltage parallel signal transmission, the same control system belongs to the instrumentation between the public terminal, easy to detect the instrument, regulating instrumentation, computers, alarm devices with, and convenient wiring.

The reason for using 4~20mA.DC as the contact signal between the field instrument and the control room instrument is that: because the distance between the field and the control room is far, the resistance of the connecting wires is large, if the voltage signal is used for remote transmission, it is better than the resistance of the wires and the voltage division of the input resistance of the receiving instrument, which will produce a large error, while using the signal of the constant current source as the remote transmission, as long as the transmission loop does not branch, the current in the loop will not change with the length of the wires, and the current in the loop will not change with the length of the wires. change with the length of the wire, thus ensuring the accuracy of the transmission.

The reason for using 1~5V.DC as the contact signal between the instruments in the control room is: in order to facilitate the common reception of the same signal by multiple instruments and to facilitate the wiring and the formation of various complex control systems. If the current source as a contact signal, when more than one instrument to receive the same signal, their input resistance must be connected in series, which will make the maximum load resistance exceeds the load capacity of the transmitter instrument, and the negative end of the signal of the receiving instrument potential is different, it will introduce interference, and can not be done in a single centralized power supply.

The use of voltage source signal contact, contact with the field instrumentation with the current signal must be converted to a voltage signal, the simplest way is: in the current transmission loop in series with a 250Ω standard resistor, the temperature sensor 4-20ma.DC converted to 1 ~ 5V.DC, usually by the distributor to complete this task.

Third, why transmitters choose 4 ~ 20mA.DC for transmission signal?

1, first from the field application of safety considerations

Safety focus on explosion-proof safety spark-type instrument to consider, and to control the instrument energy as a prerequisite to maintain the normal operation of the instrument static and dynamic power consumption is reduced to a minimum. Output 4 ~ 20mA.DC standard signal transmitter, its power supply voltage is usually 24V.DC, the main reason for the use of DC voltage is that you can not use large-capacity capacitors and inductors, it is only necessary to consider the transmitter and the control room instrumentation connected to the distribution of capacitance and inductance of the wire, such as 2mm 2 of the wire and its capacitance distribution of 0.05μ/km or so; for a single wire inductance of 0.4mH/km or so; much lower than the detonation of hydrogen. km or so; much lower than the value of the detonation of hydrogen, which is obviously very favorable to explosion-proof.

2, the transmission of signals with a current source is better than the voltage source

Because of the distance between the scene and the control room, connecting the wire resistance is large, if the voltage source signal transmission, due to the wire resistance and receiving instrument input resistance of the voltage division, will produce a large error, if the current source signal as a remote transmission, as long as the transmission loop does not appear branch, the current in the loop will not change with the length of the wire, thus ensuring the accuracy of the transmission.

3, the maximum signal current selection of 20mA reasons

The choice of maximum current 20mA is based on safety, practicality, power consumption, cost considerations. Safe spark instrumentation can only be used for low voltage, low current, 4 ~ 20mA current and 24V.DC is also safe for flammable hydrogen, for 24V.DC hydrogen detonation current of 200mA, far more than 20mA, in addition to comprehensively consider the connection distance between the production site instrumentation, with the load and other factors; and power consumption and cost issues, the requirements of the electronic components, power supply power requirements and other factors. Requirements for electronic components, power supply and other factors.

4, the starting current of the signal to choose the reason for 4mA

Output of 4 ~ 20mA transmitter to the majority of two-wire system, two-wire system, that is, the power supply, the load is connected in series, there is a common point, and the field transmitter and the control room instrumentation between the signal contact and power supply with only two wires. Why is the starting point signal is not 0mA, which is based on two points: First, the transmitter circuit will not work without static current, the signal starting point current 4mA.DC, not coincide with the mechanical zero, this "live zero" is conducive to the identification of power outages and disconnections and other faults.

Four, the origin of 4 ~ 20mA sensor?

The reason for using the current signal is not easy to be disturbed, and the current source of internal resistance is infinite, wire resistance in series in the loop does not affect the accuracy, in the ordinary twisted-pair cable can be transmitted hundreds of meters.

The reason for using the current signal is not easy to be disturbed, because the amplitude of the noise voltage in the industrial field may reach several V, but the power of the noise is very weak, so the noise current is usually less than nA level, so the error brought to the 4-20mA transmission is very small; the internal resistance of the current source tends to be infinite, and the lead wire resistor is connected in series in the loop without affecting the accuracy, so it can be transmitted hundreds of meters on the common twisted-pair cable; due to the large internal resistance of the current source and the constant resistance, the lead wire resistance is connected in series in the loop without affecting the accuracy, so it can be transmitted hundreds of meters on the common twisted-pair cable. Due to the large internal resistance of the current source and the constant current output, we only need to place a 250 ohm resistor to ground on the receiving end to obtain 0-5V voltage, the advantage of low input impedance receiver is that the nA level of input current noise produces only a very weak voltage noise.

The upper limit of 20mA is taken because of explosion-proof requirements: the spark energy caused by the interruption of a 20mA current is not sufficient to ignite the gas. The reason why the lower limit is not taken as 0mA is in order to be able to detect line breaks: in normal operation it will not be lower than 4mA, and when the transmission line is broken due to a fault, the loop current drops to 0. 2mA is often taken as the alarm value for a broken line. Current transmitter will be converted into physical quantities of 4 ~ 20mA current output, there must be an external power supply for its power supply. The most typical is the transmitter needs two power lines, plus two current output line, a total of 4 wires to be connected, called four-wire transmitter. Of course, the current output can be common with the power supply a common line common VCC or GND, can save a line, called three-wire transmitter. In fact, you may notice that the 4-20mA current itself can power the transmitter. The transmitter in the circuit is equivalent to a special load, the special thing is that the transmitter's power consumption current between 4-20mA according to the 4 20ma temperature sensor output and change. The display meter is simply strung in the circuit. This type of transmitter requires only two external wires and is therefore called a two-wire transmitter. The lower limit of the industrial current loop standard is 4mA, so the transmitter is supplied with at least 4mA as long as it is within the range.

Therefore, the 4-20mA signal output is generally not easily disturbed and safe and reliable, so the industry is commonly used in the two-wire 4-20mA power output signal. But in order to better deal with the 4 20ma temperature sensor's signal, there are more other forms of output signals: 3.33MV/V; 2MV/V; 0-5V; 0-10V and so on.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist