BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

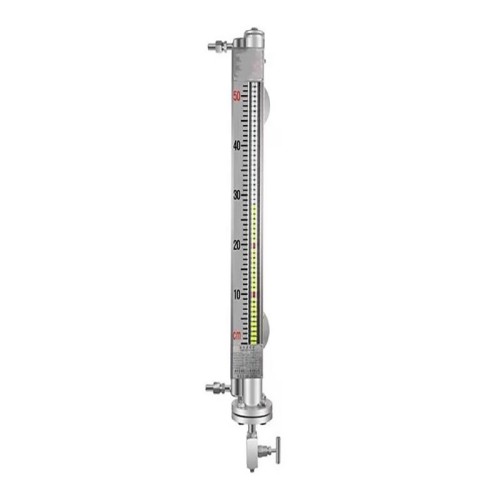

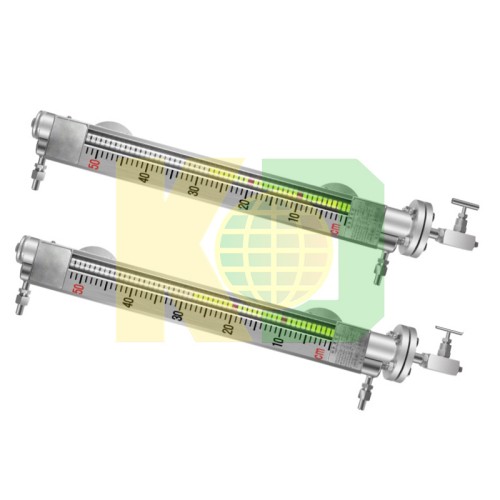

Vacuum-jacketed magnetic flap level gauge is a kind of level measuring instrument which is very suitable for working in low temperature. In order to effectively prevent the measuring medium from freezing at low temperature and cannot be measured, the measuring medium needs to be kept in a liquid and measurable liquid state by exogenous heating measures. Therefore, vacuum-jacketed magnetic flap level meters have been developed for level measurement in low temperature environments. The vacuum jacketed magnetic flap level meter often fails in the process of practical application, and the causes of these failures are various, either caused by the failure of a single component, or by the failure of multiple components at the same time. This article on the vacuum jacketed magnetic level gauge in the process of application of common failures and their treatment are introduced as follows:

A vacuum jacketed magnetic flap level meter common failures

(A) display panel display failure

1, the distance between the display panel and the float is too large, and the driving force of the magnet of the magnetic float is not enough, resulting in the flip flop can not be turned over.

2, the gap between the flip-flop and the rail is not designed (such as the gap is too small), resulting in high friction, resulting in the flip-flop can not be turned.

3, the magnet in the flip flop is too small or magnetic level indicator force disappears, resulting in the flip flop can not flip or flip abnormal.

4, water or dust and other impurities seeped into the display panel, resulting in the flip flop flip difficulties.

5、The ambient temperature is low, the medium is frozen, the magnetic float cannot move, and the flip flop cannot display the liquid level normally.

(B) the local display is normal, but the reed switch remote transmitter display abnormal

The causes of this failure are usually the following:

1, resistance deficiency welding.

2, the pressure exceeds the rated value, resulting in damage to the switch.

3, domestic glass tube reed switch fragile reed switch short-circuit, resulting in abnormal teletransmission.

4, in the case of high medium temperature, the metal sheet is heated and expanded, because the metal contact gap of the reed tube is small, easy to appear closed state.

(C) the reed tube remote teletransmitter and vacuum jacketed magnetic flap level meter are abnormal

The fault is usually a magnetic float failure, there are the following two situations:

Fault phenomenon one: the magnetic float type level gauge is stuck.

Magnetic float is stuck, there are usually several reasons:

1, When the magnetic float is used for a period of time, the magnetic float may be stuck due to the presence of impurities and cannot be moved.

2、The installation angle of the float is less than 87 degrees, which leads to tilt and affects the up and down movement of the magnetic float.

3、The magnetic float is stuck due to its own magnetic adsorption of iron filings or other contaminants, resulting in jamming.

4、The ambient temperature is too low, the medium is frozen, the magnetic float can not move.

5, vacuum jacketed magnetic flap level meter across the steel platform, the distance between the steel plate is too close to produce. Therefore, the installation through the steel platform requires special attention to the spacing between the level meter connecting pipe wall and the cutting edge of the platform. According to the field experience, this spacing is about 100mm that can ensure that the magnetic float level gauge does not affect.

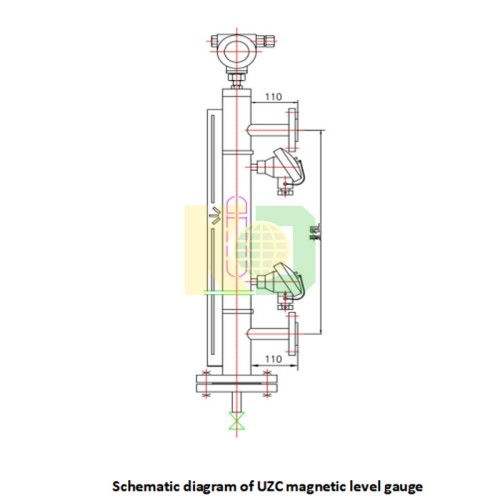

Fault phenomenon two: magnetic float damage

The magnetic float is damaged, there are usually several reasons:

1, the strength of the magnetic float type level transmitter is not enough, resulting in over-pressure concave to the inside, deflated.

2、In the welding place is not welded through or leakage welding, resulting in the float is under pressure when the weld cracked, magnetic float internal water.

3、The use of magnetic float is too long, or long-term high temperature use, demagnetization phenomenon.

4、The magnet in the magnetic float is loose, and the magnetic float gauge cannot work.

Second, the vacuum jacketed magnetic flap level meter troubleshooting and prevention

Know the cause of the failure, the problem is also solved half. We can for the vacuum jacketed magnetic flap level meter in the use of failure, targeted to deal with. Compared with the failure to deal with, the correct daily use and maintenance is more important and critical, here it is recommended that users in the daily use of magnetic flap level meter, pay special attention to first open the upper gate valve, then open the lower gate valve. This is because the bottom of the magnetic flap level meter connecting tube is equipped with a thrust spring to protect the float, otherwise, the role of large differential pressure may crash the float resulting in the level meter can not be used. In addition, it should be noted that the float should not be checked by pulling up and down with a strong magnet outside the connecting tube, in order to avoid the magnetic float level transmitter changing polarity due to magnetization, or even weakening the float magnetism so that it is difficult to work properly. In order to ensure the vacuum status of the vacuum jacket, we need to add vacuum measurement for the vacuum jacket regularly.

The above is the "vacuum jacketed magnetic flip-flop level meter common failures and treatment" related to the introduction, such as to understand more level switch (level switch, level switch), level meter (level meter, level meter) and other level measurement instrumentation knowledge, welcome to pay attention to my consulting us!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist