BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

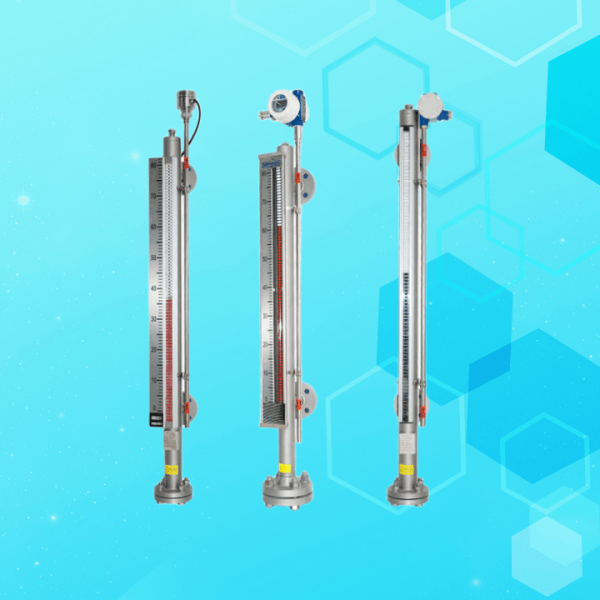

Remote magnetic flap level gauge is a kind of liquid level measuring instrument which is composed of reed tube remote transmitter and magnetic flap level meter combined together. It transmits the level signal from the site to the machine room or control room in the form of 4-20mA current, so as to grasp the level of the tank remotely and facilitate the purpose of real-time control. In order to better understand the remote magnetic flap level meter, this paper introduces the main uses and daily maintenance of the remote magnetic flap level meter as follows.

A, the main use of the remote magnetic flap level meter

Remote magnetic flap level meter has a large measuring range and is not limited by the height of the storage tank. Simple structure, easy installation, low maintenance cost. The indicator mechanism is completely isolated from the measured medium, with high safety, stability and reliability.

It is mainly used for measuring and displaying the liquid level of various types of storage tanks, storage tanks, storage pools, reaction tanks, fermentation tanks, oil fields, liquefied gas, liquid hydrogen, strong acid and alkali liquids, etc.

Second, the installation and maintenance of the remote magnetic flap level meter

In the process of using the remote magnetic flap level meter, the remote magnetic flap level meter should be well installed and daily maintenance, generally should do the following:

1. When choosing the installation location of the telemagnetic flip-plate level meter, attention should be paid to avoid or install away from the import and export of the material medium.

2. If the teletransmission magnetic flap level meter exceeds a certain length (such as ordinary type > 3 meters, anti-corrosion type > 2 meters), in order to ensure the safety of the instrument, the level meter needs to be reinforced with additional flanges or fixed support in the ear climb to make the instrument more solid.

3. When installing the remote transmitter, the remote transmitter should be installed close to the dominant tube of the magnetic level transmitter and fixed with stainless steel holding hoop, but do not use iron to avoid affecting the magnetism of the meter and measurement accuracy.

4. After installation, attention should be paid to the commissioning of the instrument in accordance with a certain order. Generally should first open the upper guide valve, then slowly open the lower valve, let the medium smoothly into the main tube, observe whether the magnetic red and white flip flop flip is normal, and then close the lower guide valve, open the drain valve, let the liquid level in the main tube drop, according to this method three times, still normal, can be put into operation. It should be noted that when the medium enters the leading tube, it must enter smoothly, if the medium sharply impacts the float, it is easy to cause violent fluctuations of the float, which will affect the accuracy of the display.

Finally, attention should be paid to the characteristics of the media, the leading tube of the remote magnetic flap level meter for occasional cleaning, in order to clean off the impurities in the leading tube, to ensure the smooth operation of the float.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist