BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

In the process of burning coal in thermal power plants, a large amount of coal ash is generated. This coal ash is usually collected in coal ash bins and coal ash hoppers. In order to avoid the stored coal ash from bubbling up the tank, it is quite necessary to detect and control the height of the coal ash material level. The general practice is that a 4-20mA continuous quantity output meter will be installed on the tank as well as a switching quantity output limit level alarm meter to do overflow prevention tank. Therefore, the selection of level measurement instrumentation for coal ash silos and coal ash hoppers in power plants is very important. In this paper, we will discuss the selection of level measuring instruments for coal ash silo and coal ash hopper in power plants for the reference of the general instrument users.

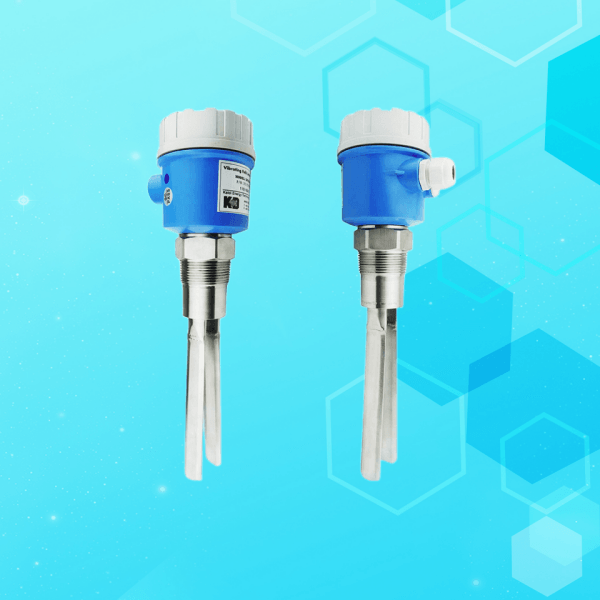

I. Switching output level switch

Switching output level switches mainly include RF conductivity level switches, resistance level switches, tuning fork level switches, etc. The working principle can be referred to the corresponding product page on the official website of Kaidi Energy Technology Co.

For the consideration of product stability, it is recommended to use vibrating tuning fork level switch for tank limit alarm. The tuning fork level switch has the characteristics of solid and reliable structure, no split parts, low maintenance and overhaul cost, and not affected by the change of dielectric constant, which can effectively prevent the overflow of the hopper.

Two, continuous volume output level meter

1、3D Level Scanner

The 3D level scanner is based on a two-dimensional array beamformer transmitting low frequency pulses to receive the echoes from the material inside the silo, chamber or other container, the digital signal processor of the device samples and analyzes the received signals, and by estimating the arrival time and direction of the echoes, the processor forms a three-dimensional image of the material surface. This image is processed by a proprietary computational method to generate a 3D image that can be displayed on a remote screen. The device can accurately derive the volume and mass of the material, enabling process level monitoring and inventory control to reach a new level.

Radar level meter is a measuring instrument based on the principle of time travel, radar waves run at the speed of light, the running time can be converted into level signals through electronic components. The probe sends out high frequency pulse and propagates, when the pulse meets the material surface it is reflected back and received by the receiver inside the meter, and the distance signal is converted into a level signal.

3、Heavy hammer level meter

The intelligent motor drive system of the heavy hammer level meter controls the heavy hammer tied to the stainless steel cable to fall, and the hammer stops falling when it touches the surface of the medium, and then the heavy hammer level meter changes the direction of rotation of the motor to retract the hammer. During the measurement process, the hammer level meter obtains the level signal through the precise measurement of special double optical sensors, and converts the level signal into a 4~20mA analog signal.

Compared with the high cost 3D scanner and the heavy hammer level meter which is easy to bury the hammer, the non-contact high frequency radar level meter is not sensitive to dust and noise, so the high frequency radar level meter is an ideal choice for the level measurement of silo.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist