BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

Differential pressure transmitter has become an important part of the measurement instrumentation, with other instrumentation, differential pressure transmitter is in a period of rapid development and change. Today we want to understand is the development of differential pressure transmitter overview.Initially, differential pressure measurements were realized by means of the force balance principle. The force balance differential pressure transmitter utilizes the negative feedback principle of depth.(The principle of feedback is a concept in physics that refers to the effect of sending a portion of the energy from the output circuit of an amplifier back into the input circuit to enhance or attenuate the input signal. Psychology has borrowed this concept to illustrate that a learner's knowledge of his or her own learning outcomes, which in turn serves as reinforcement, encourages the learner to study harder, and thus improves learning efficiency. This psychological phenomenon is called the "feedback effect". Feedback effect can guide enterprise management and learning work, is a very important management theorem.)To reduce the sensitive element modulus with the environmental temperature change, elastic hysteresis and its nonlinear deformation and other elements of the direct impact, and thus ensure the accuracy of the measurement. However, this method is complex and bulky, and there are static pressure errors that are difficult to eliminate.

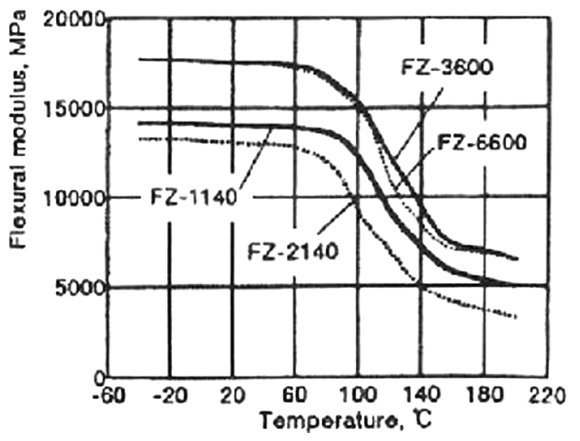

Due to the development of new materials, the modulus of elasticity has emerged(Modulus of elasticity is the ratio of stress to strain in the elastic range, in Pa or MPa . The modulus of elasticity can measure the macroscopic mechanical properties of materials at room temperature and under static load, and is the main basis for determining various engineering design parameters. It is also used to measure the degree of rock plasticity in the process of geological drilling)

and elastic materials with very small temperature coefficients. In particular, the development of electronic detection technology makes the detection of small displacements possible, thus allowing small deformation of elastic materials, which further reduces the variance caused by nonlinearity and elastic hysteresis. These are open-loop type new differential pressure transmitter development has created the conditions. The capacitive differential pressure transmitters commonly used on the market today are of this type. Differential pressure transmitter not only in principle from the closed loop to the fundamental change of the open loop, and has a simple structure, reliable operation, no static pressure error, easy maintenance characteristics .

With the updating of science and technology, various other new types of transmitters and vibrating string and diffusion silicon transmitters have also been successfully developed and put into production and use. The successful development of intelligent differential pressure transmitter 4 20ma is the product of the development of computer and communication technology. Intelligent differential pressure transmitter signal conversion accuracy is high, the direct impact of ambient temperature change is small, the direct impact of static pressure and vibration is small, and the range ratio is particularly small. Therefore, intelligent differential pressure transmitter can meet the needs of a variety of measurement environments. Another feature of intelligent differential pressure transmitter is that it has good communication function. Through the simple operation of the field communicator of the intelligent differential pressure transmitter, remote setting, changing and tuning can be realized, and all these functions bring great convenience for the user's on-site use and maintenance.

Nowadays, due to the development of industrial modernization, automation system is more and more large-scale and complexity, industrial production links from the past a single to ensure the stability of production operation for the purpose of today's large-scale centralized and optimal control. Also, the expansion of the application field, but also need to meet the differential pressure transmitter more and more multi-functional, performance requirements are becoming more and more demanding. Simply put, that is, the differential pressure transmitter 4 20ma needs to meet the high accuracy, adaptability to the measurement object and the use of the environment, miniaturization, digitalization, easy installation and maintenance, especially the reliability of these properties directly affect the reliability and safety of the entire automation system.

The development of differential pressure transmitters is dependent on technological innovation and progress in various industries. At the same time, the application of the new differential pressure transmitter, but also for all walks of life to provide more convenient sensing measurement and monitoring program .

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist